High containment split butterfly valve

Powder containment is the cornerstone of chemical and pharmaceutical manufacturing. Floating particles do not only represent efficiency loss but serious hazards too. Lack of tightness during the powder discharge process leads to cross-contamination and operational health risks.

Dock transfer systems squarely in place

The ASBV active/passive valve interface by Andocksysteme locks into position, minimizing exposure of material during powder discharge. The system has two split valves – one active, one passive – that can be easily and reliably centred on each other at a tolerance of ± 14 mm.

Once the units are docked, the valve discs open simultaneously, preventing exposure of the products during transfers. The dust-tight environment achieves contamination values lower than 1µg/m3.

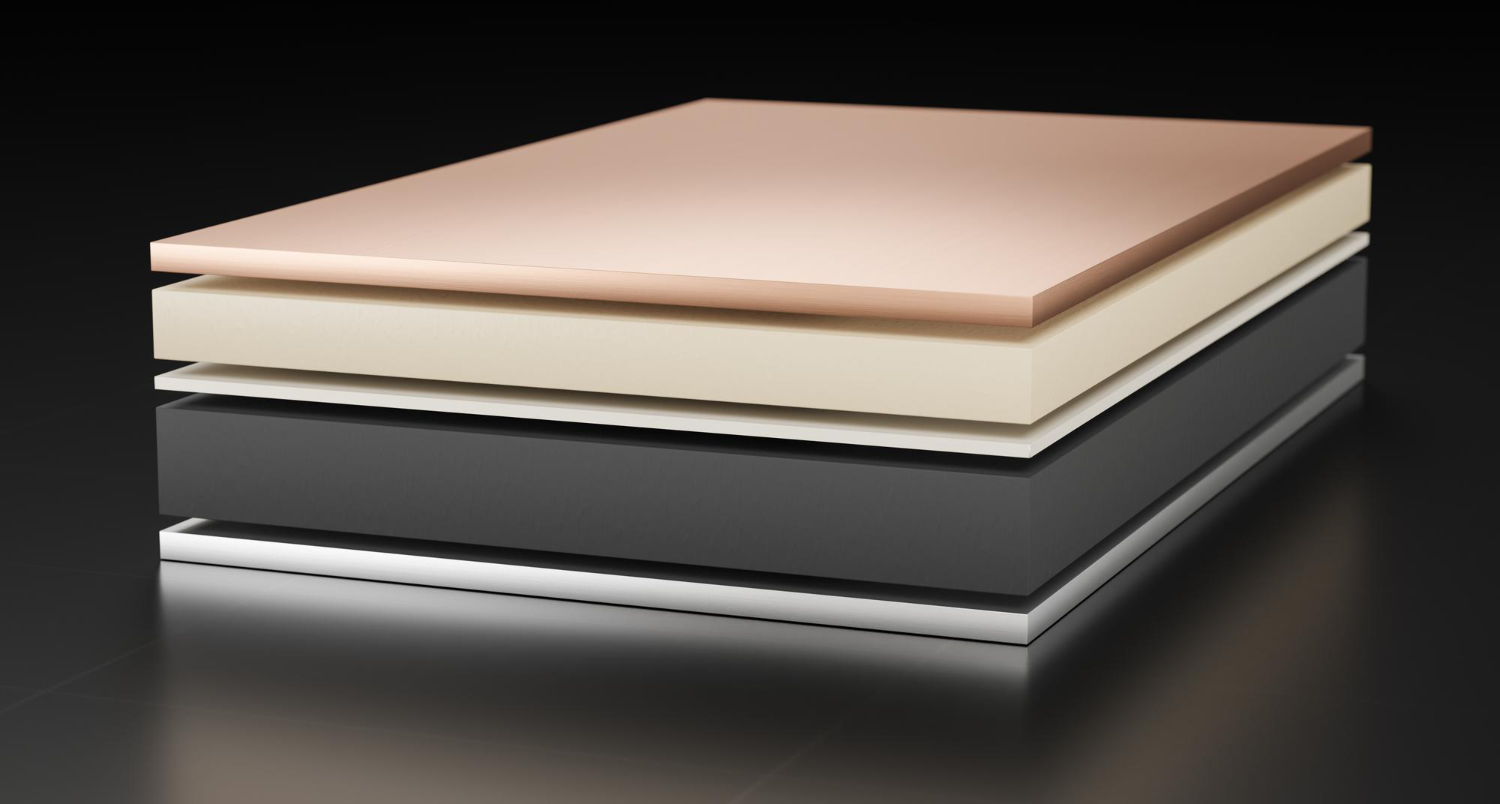

The ASBV solution is fitted with EPDM seals and are optional with a wide range of materials, such as PTFE, offering top-range chemical resistance. All seals are made from FDA-approved materials and can handle a wide range of temperatures as well as explosion-proof executions.

Washing the ASBV interface is simple as the system can be connected to a WIP loop to flush out residual powders. These containment solutions serve applications with an exceptional performance and are easy to be integrated. Moreover, high quality parts and reduced complexity drives simple maintenance.

Benefits

- Manual or automatic operation

- Passive valve can be docked in two positions (180° turned)

- Easy removal of the insert in contact with the product

- Biggest range of valve sizes DN 50 to DN 300

- Available in stainless steel 1.4404, optional HC 22 or other materials

- Optional add-ons to increase the containment performance