Let's Make Pharmaceutical Powders

Find innovative pharmaceutical powder equipment and connect directly with world-leading technology suppliers

Pharmaceutical powders provide longer shelf life and better stability than liquid dosage forms. But the processing of pharmaceutical powders is crucial for growing segments besides pharmacy. Functional foods and cosmetics formulated with active ingredients and excipients depend on powdered forms to fulfill their promises.

Innovative equipment for pharmaceutical powder

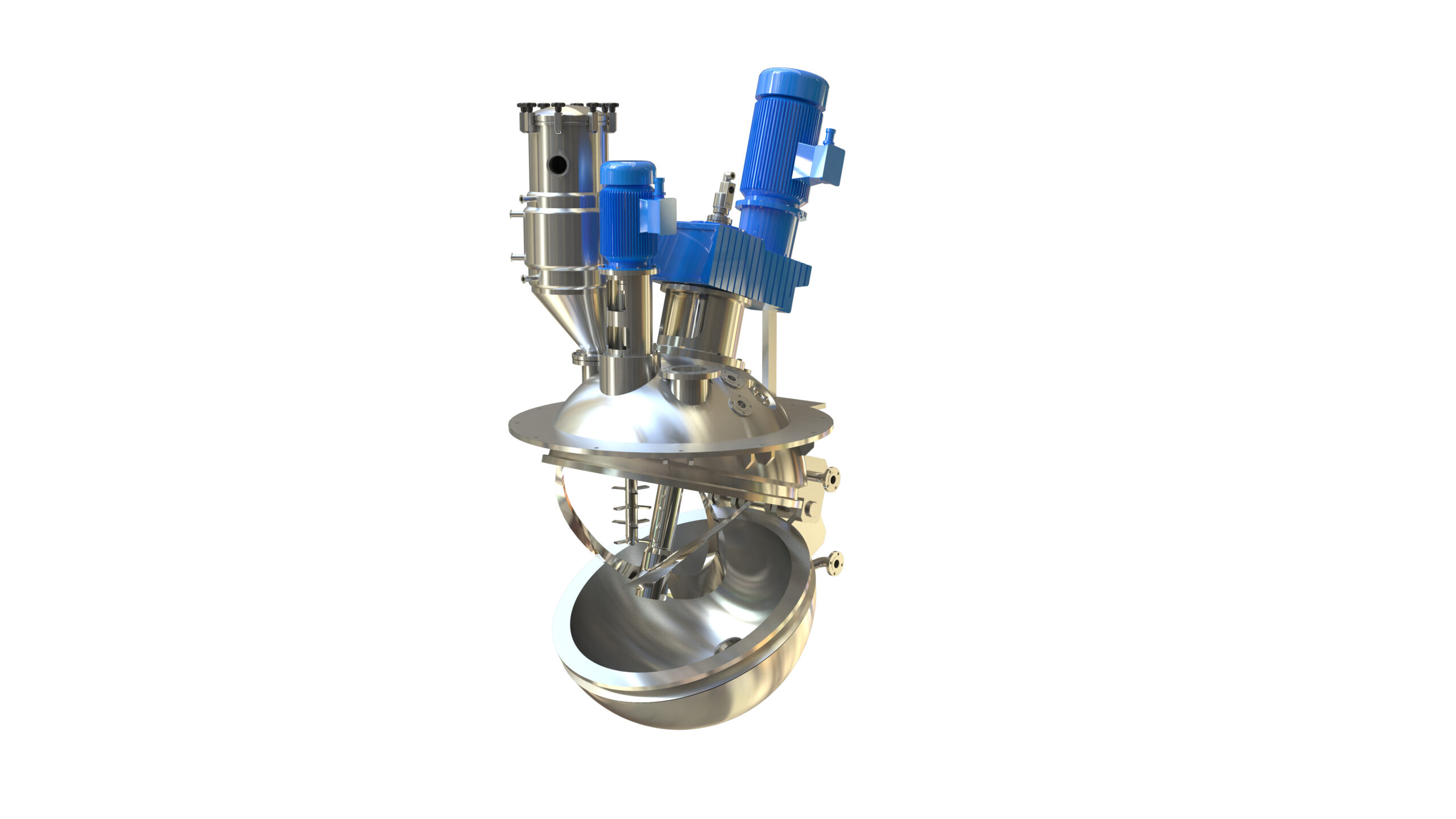

3D powder mixer for active pharmaceutical ingredients

Proper mixing and homogenization are essential to achieve a reliabl...

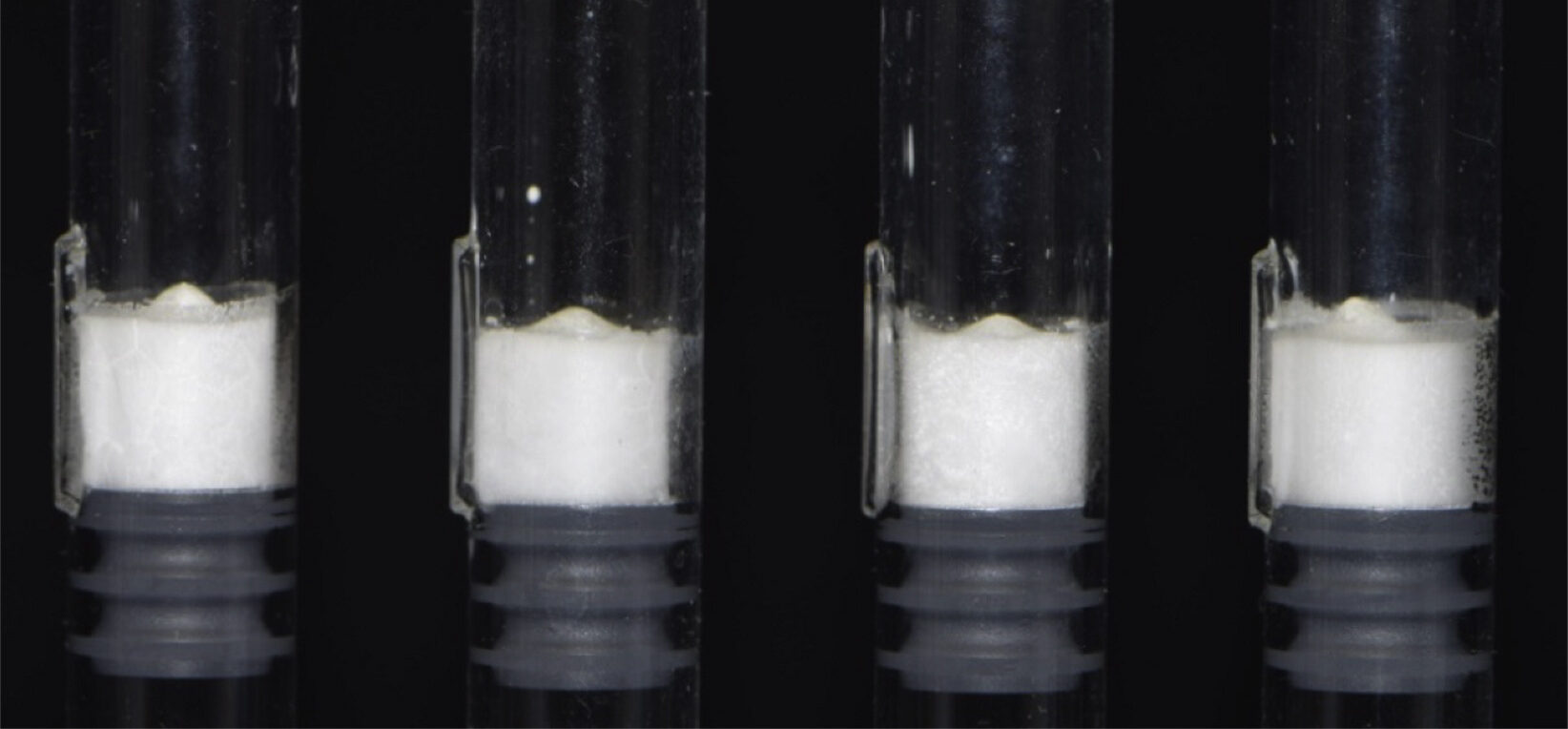

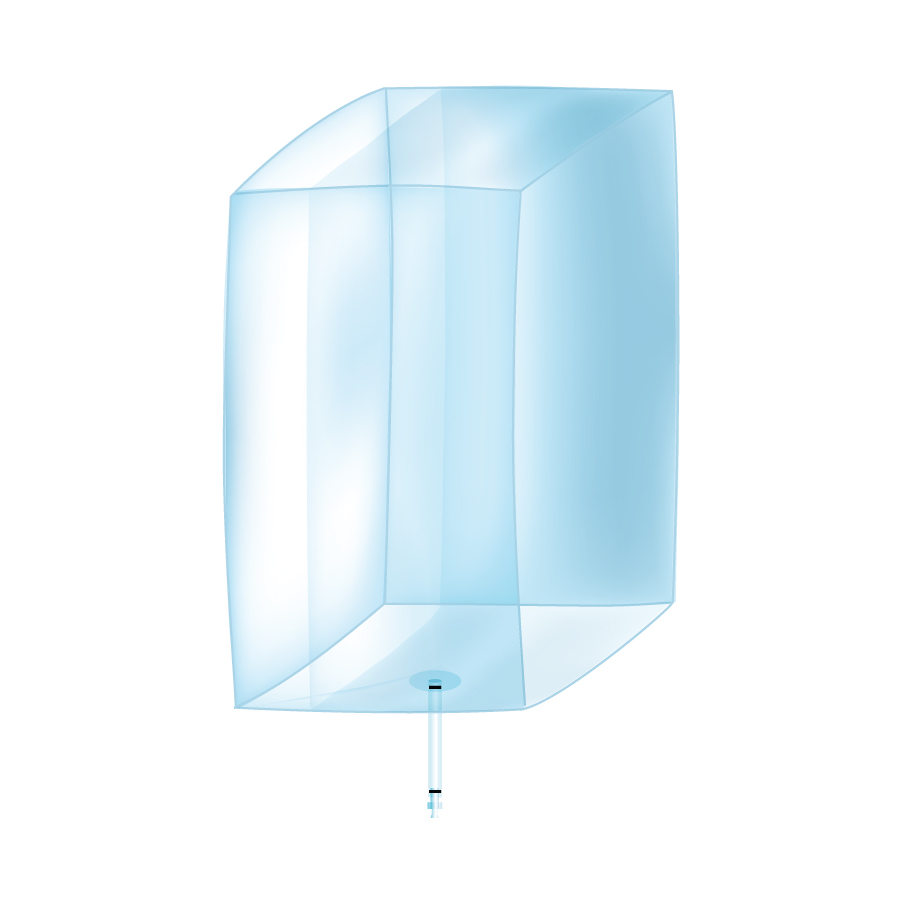

API powders storage bottle

Users who prefer rigid storage over single-use pharma charge bags, require lightweight solutions ...

Bin blender for pharmaceutical powder mixing

Achieve uniform mixing and homogenization of dry powders directly in storage ...

Capsule filling system for pharmaceutical production

Efficiently fill and lock capsules of various sizes with exceptional...

Stories about pharmaceutical powder

Scientifically tested continuous drying for your tablets

Aim your safety standards high, while granulating dry

Discover the best mix for your blending application

Wet milling: The revolution in the API production

Closing the containment loop in HPAPI manufacturing

Lowering heat stresses on API by reducing friction

Tell us about your production challenge

Reduce particle sizes before manufacturing pharmaceutical powders

Variable particle sizes of pharmaceutical powders develop significant challenges in the manufacturing process. Polydisperse materials have poor mixing characteristics and may lead to clumping instead of particle cohesion. Therefore, powder characterization is an important part of the production process.

Mill your powders before mixing the formula to ensure a homogeneous particle size distribution. The ball mill produces impact and attrition between the material and the moving balls and is suitable for wet and dry grinding processes. Although it downsizes particles to very fine grades, it does not very well handle soft, fibrous materials. A hammer mill adapts better for these kinds of powders.

Processing of pharmaceutical powders improves the bioavailability of active ingredients

The fine diameters of pharmaceutical powders achieve high penetrability, making them effective delivery systems for intra-respiratory solutions. Their small particles have a faster dissolution rate and better bioavailability.

However, unless distributed in mono-dose formats, dosing can be inaccurate. Powders typically also have an offensive aftertaste compared to other oral medicines.

Contain pharmaceutical powders in sealed packaging

Non-potent drugs manufactured into pharmaceutical powders are dispensed as bulk products. Medicated powders such as antacids or topical anti-infectives may be stored in containers, but they must ensure airtight closure.

Headache powder, laxative powders, and other products formulated from potent ingredients are prepackaged into single-dose portions. Divided powders, as they are called, reduce the risk of overdosing, so dosing and weighing systems are indispensable for production.

Which pharmaceutical powder technology do you need?

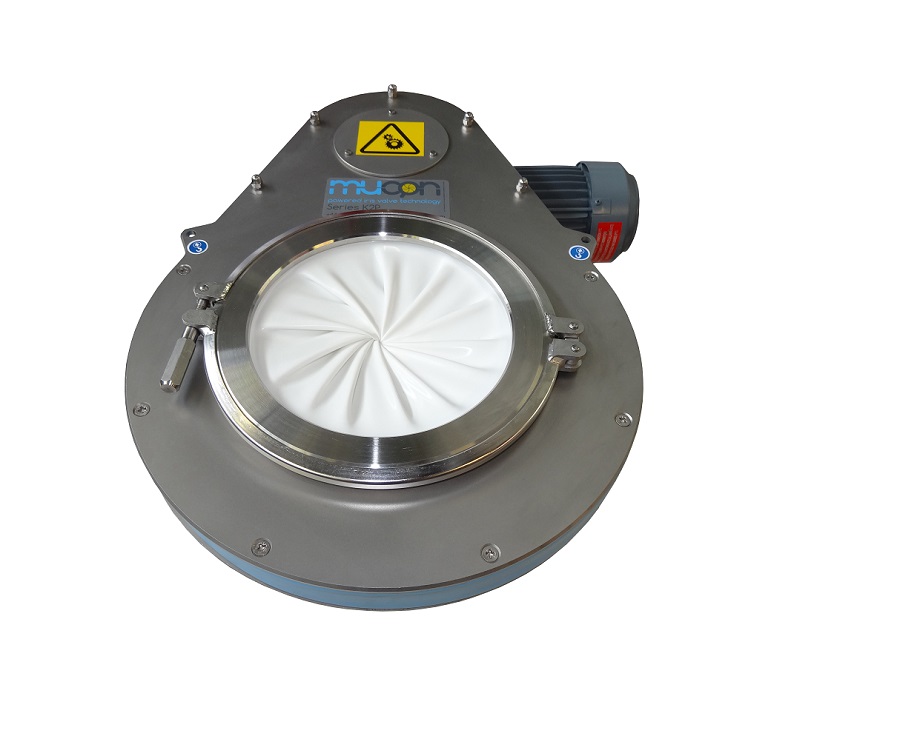

Industrial powder security screening and de-agglomeration

Ensure product purity by efficiently screening and de-agglomer...

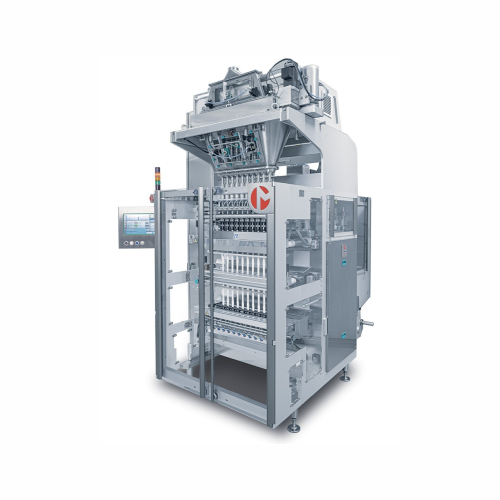

Stickpack filling and closing system for pharmaceutical powders

Achieve precise dosing and secure packaging for pharmace...

Homogenous blending solution for powders and granules

Achieve precise, homogenous blending of challenging materials like ...

High speed powder dosing and stoppering for antibiotics

Address the threat of antibiotic-resistant bacteria with precisio...

Continuous mixing for fine and cohesive powders

Achieve unparalleled mixing precision for cohesive powders while reducing ...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

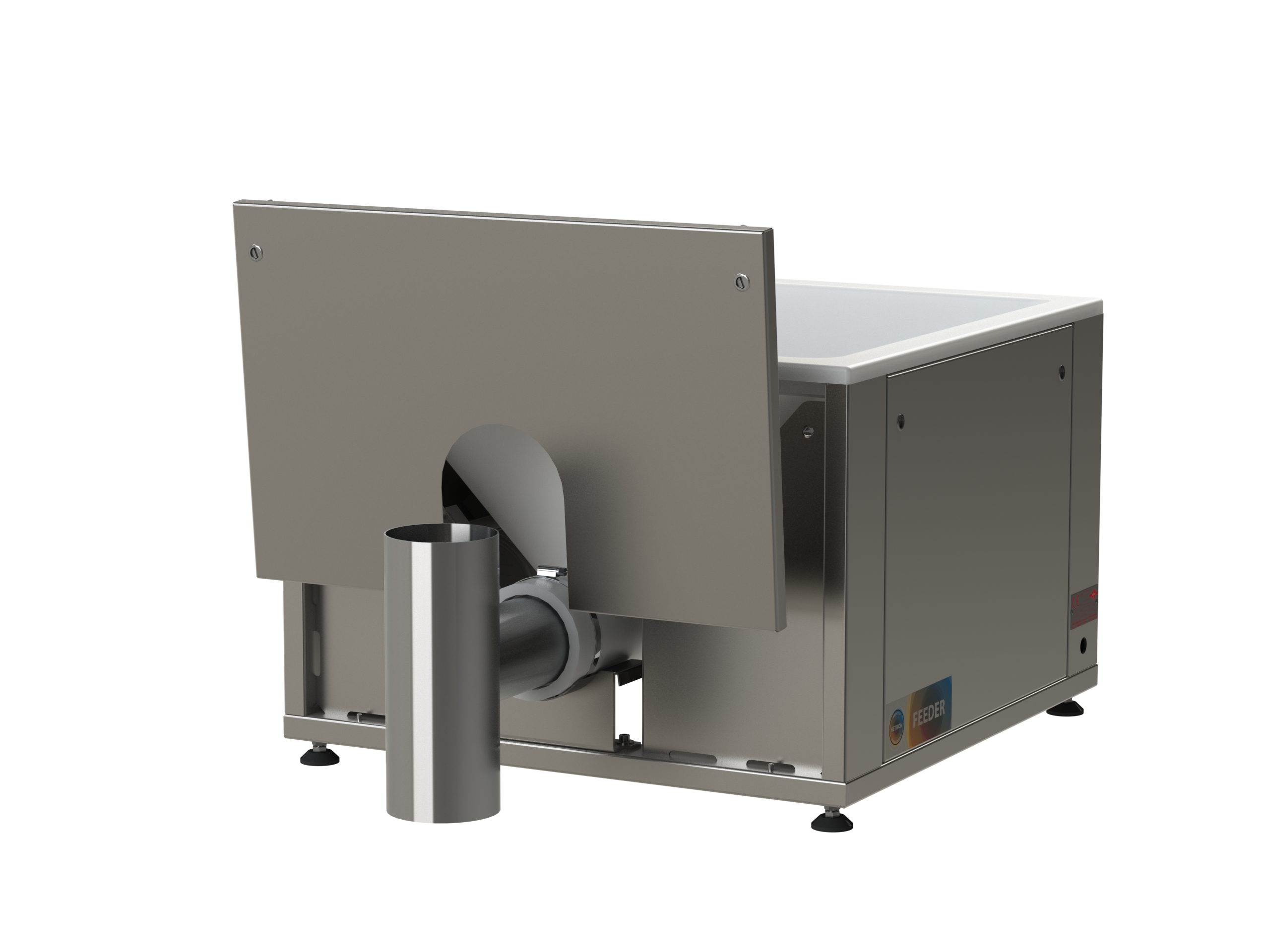

Powder feeder for consistent mixing in pan coating processes

Ensure precise dosing and mixing of pharmaceutical powders ...

Pharmaceutical powder bag filling system

Ensure precision in pharmaceutical formulations with a system that fills high-spee...

Powder dosing system for development and small batches

Streamline lab-scale pharmaceutical production with a versatile po...

Powder dosing machine for laboratory applications

Achieve precise powder dosing and streamline your R&D processes wi...

Auger dosing unit for powder dosing in pharmaceuticals

Ensure precise and flexible dosing of pharmaceutical powders with ...

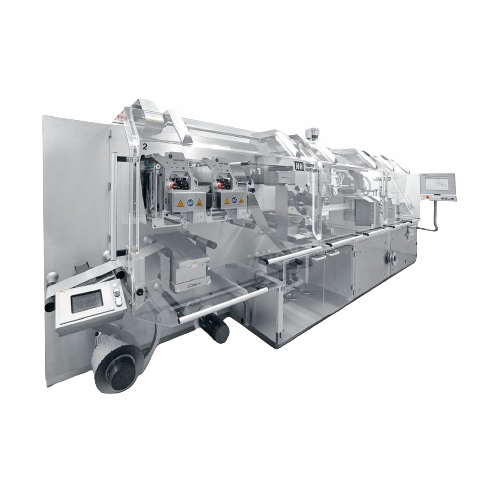

Commercial blister filling solution for dry powder

Efficiently fill and seal blister packs with precision, ensuring consi...

Capsule filling system for powder, pellets, and tablets

Optimize capsule production with rapid dosing changes, minimizing...

Semi-automatic powder dosing system

Achieve precise micro-dosing for pharmaceutical powders with a flexible system ideal fo...

Particle sizing for powders and suspensions

Optimize particle shape and size analysis with rapid, reproducible results for...

Benchtop laboratory powder blender

Perfect for R&D labs needing precise, small-batch powder blending and mixing, this ...

Tipping and filling line for bulk Api powder production

Ensure precise and aseptic handling of pharmaceutical powders wit...

Production isolator for powder preparation and weighing

Ensure precise weighing and safe handling of pharmaceutical powde...

Dry powder filling isolator for cgmp production

Achieve precise powder dosage and secure containment for hazardous materia...

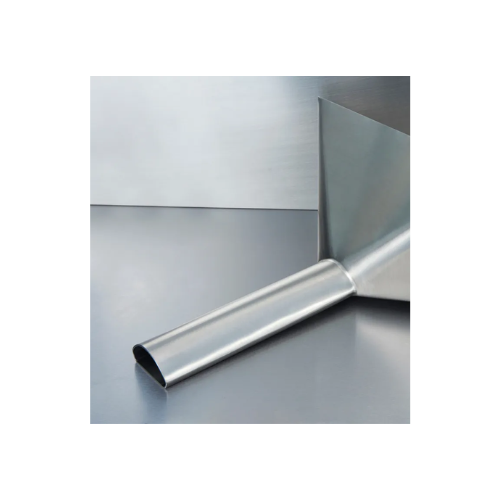

Powder dispensing funnel

Enhance powder handling accuracy while minimizing product loss with a precision-engineered dispensin...

Plastic containers for bulk powder transfer

Maximize your facility space with innovative plastic containers designed for e...

Intermittent motion powder dosing and capping system

Ensure precise powder dosing and secure capping in one seamless step...

Automatic bagging station for powdery products

Streamline your packaging line with a reliable solution designed for high-s...

Jet mill for micronizing pharmaceutical powders

Achieve precise particle size reduction with a jet mill that leverages hig...

Bin blender for pharmaceutical powder mixing

Achieve uniform mixing and homogenization of dry powders directly in storage ...

Powder dosing and weighing system

Optimize precision in pharmaceutical processing with a system designed to ensure accurate...

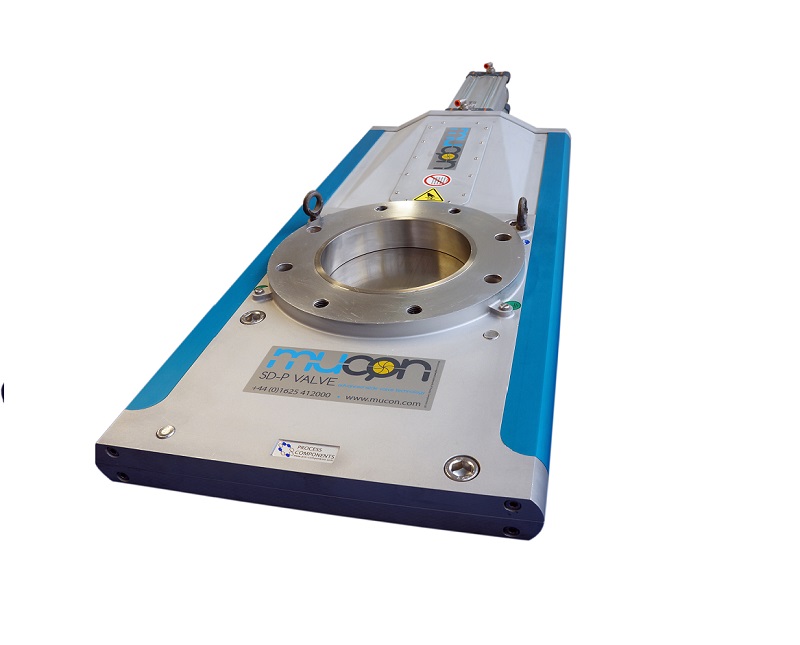

Containment valves for pharmaceutical powder transfer

Ensure safe transfer of highly potent pharmaceuticals with this mod...

Lean phase pressure conveying for powder handling

Effortlessly transport and manage powdered materials with lean phase pr...

Efficient ribbon mixers for precise powder blending

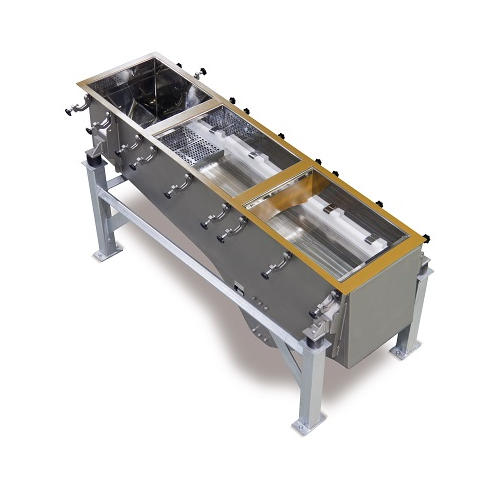

Achieve consistent and uniform blending with this advanced U-Trough m...

Flat-bottom twin-screw feeder for precise powder feeding

Achieve precise control in powder dispensing with this flat-bott...

Gravimetric twin screw feeders for pharma powders

Optimize feeding for challenging materials with dust and water-resistan...

High-speed wrapping machine for chocolate or compressed powder products

For confectionery and pharmaceutical operations...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

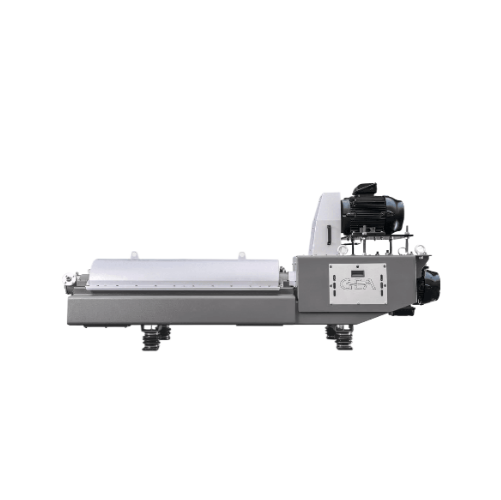

Dry granulator for pharmaceutical powders

In pharmaceutical industries, where large-volume production is the norm, compact...

Accurate multiple dosing system for powders

Dosing multiple powders in a batch process is time inefficient, especially whe...

High-speed powder dosing system

Balancing speed and accuracy in powder dosing is crucial to fulfilling production viability....

Powder micro-dosing system

Pharmaceutical powders in metered doses demand maximum filling precision. This is particularly ch...

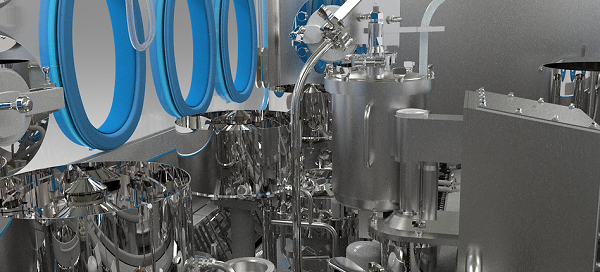

Aseptic filling machine for liquids and powders

Aseptic filling of containers such as vials, syringes, bottles, and cartri...

Pharmaceutical powder mixer

Large batches of powders with different characteristics are commonly mixed in pharmaceutical ind...

Powder transfer system

Loading powder from a container source to vessels, tanks, or mixers that are under pressure may be haz...

Fast gravimetric powder microdosing 50 - 200 g

Micro-dosing powders of high-value food or chemical products can be challen...

Gravimetric powder microdosing 2 - 100 g

Powders and granules are commonly dosed for the manufacturing of pharmaceuticals, ...

Gravimetric powder microdosing 0.400 - 2 g

If you need to process high value food, pharmaceuticals or chemicals, there is ...

Single-use powder handling bag

Containers for handling pharmaceutical and biopharmaceutical powders may be disposable, to av...

API powders storage bottle

Users who prefer rigid storage over single-use pharma charge bags, require lightweight solutions ...

Metal detector for pharmaceutical powders

Powdered and granulated pharmaceuticals require careful screening against metal ...

R&D V-type powder blender

Many pharmaceutical processes rely on the complete blending and homogenizing of different powdered...

Powder transfer vessel

Intermediate bulk storage of pharmaceutical product requires specialist containers. For increased effi...

Bellows for pharmaceutical powders

Thermal and mechanical changes can lead to stresses in industrial piping systems. These ...

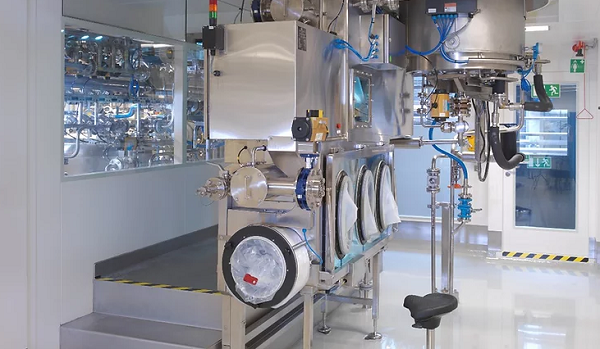

Flexible contained powder charging solution

Filling of transportation bags and discharging them into mix tanks or reactor ...

Flexible contained handling of powder transfer bags

Filling of transportation bags and discharging them into mix tanks or...

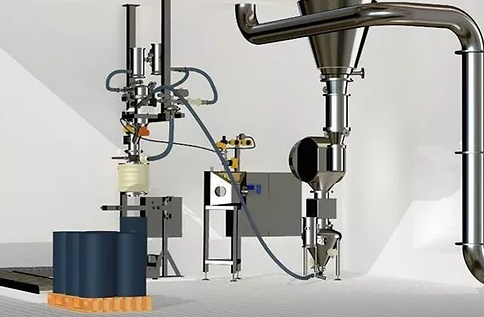

Flexible contained powder discharge into FIBC’s

Flexible intermediate bulk containers known as FIBC’s are commonly used in...

Flexible contained powder discharge into drums

Powdered products are handled every day in the pharmaceutical and bioproces...

Drum mills for fine grinding of large volumes

Achieve consistent and precise pulverization of large sample volumes with dr...

Laboratory jaw crusher for sample preparation

Achieve precise size reduction and sample preparation with this compact jaw ...

Automatic capsule filling machines

Efficiently fill capsules with precise doses of powders, liquids, and tablets to enhance...

Fluid bed processor for pharmaceutical granulation and drying

Achieve precise drying, granulation, and coating of pharma...

Lifting column for drums and containers

Streamline your production with lifting columns designed for precise handling, blen...

Capsule banding system for tamper-evident sealing

Ensure tamper-evident integrity for capsules by utilizing a precise ban...

Conical screw mixer for pharmaceutical and chemical industries

Optimize mixing precision and efficiency with a conical s...

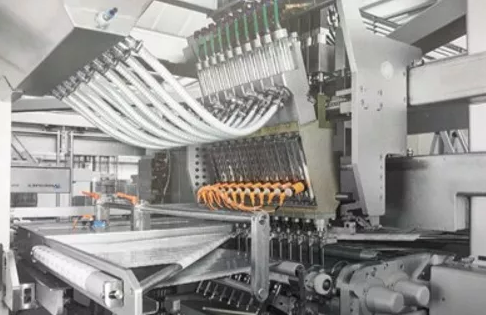

Dpi inhaler production system

Enhance your inhaler production with precision assembly and integrated dosing, filling, and ca...

Micro-dosing system for inhalation blisters

Streamline your inhalation product production with precision micro-dosing, for...

High shear wet granulation line

Achieve consistent and uniform granules with energy-efficient wet granulation designed to op...

Benchtop spray dryer for drug discovery

Optimize your formulation development with a compact spray dryer that streamlines t...

Laboratory fluid bed dryer for pharmaceutical granulation

Optimize your lab-scale drying and granulation processes with ...

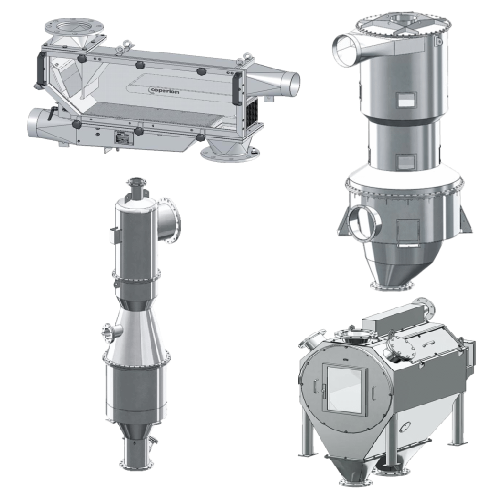

Pellet dedusting elutriators

Achieve superior purity in your production line by effectively removing dust and streamers with...

Rotary filling system for Rtu vials in pharma production

Optimize your sterile liquid and powder handling with a versatil...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

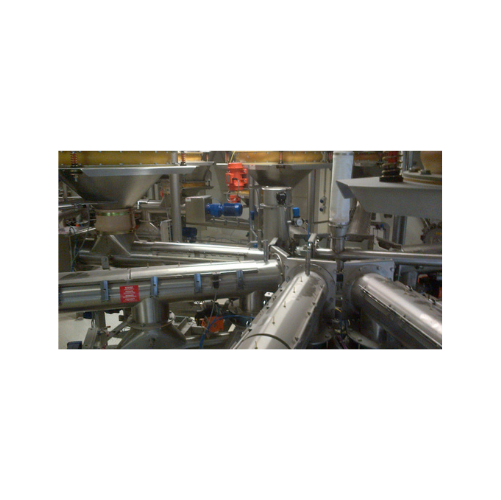

Raw material handling systems for plastic and pharmaceutical industries

Effortlessly manage and optimize the handling a...

Industrial grater and shredder for pharmaceutical and chemical applications

Optimize your production line with a versa...

Pharmaceutical roller compactor for granulation

Achieve precise granulation with streamlined compaction, ensuring consiste...

Fluid bed granulator for pharmaceutical applications

Optimize your granulation and drying processes with advanced fluid-b...

Integrated granulation train for pharmaceutical processes

Achieve precise granulation, uniform mixing, and efficient dry...

Double-sized bi-layer tablet press

Achieve high-volume production with precision using a double-sized bi-layer tablet press...

Intermediate bulk container (ibc) blending for pharmaceutical manufacturing

Streamline your pharmaceutical blending pr...

Continuous granulation and drying system for pharma production

Achieve precise control over granule quality with a conti...

Stainless steel tubular screw conveyor for bulk solids handling

Ensure precise material handling with stainless steel tu...

Stick pack packaging for pharmaceutical products

Enhance your production efficiency with compact stick pack solutions, off...

Lab scale roller compactor for dry granulation

Achieve seamless scale-up from lab development to full-scale production wit...

High accuracy hammer milling for precise particle size reduction

Achieve precise particle size control to enhance produc...

High-shear mixer granulator for pharmaceutical production

Achieve optimal granulation with enhanced mixing efficiency, r...

Vacuum rated vibro sifter for pharmaceutical materials

Ensure precise separation of impurities and achieve consistent par...

Pharmaceutical sieving equipment for high hygiene standards

Ensure the purity of pharmaceutical powders and granulates w...

Continuous wet granulator and dryer for R&D

Pharmaceutical laboratories need compact equipment to handle and produce small...

Fluidized bed system for the granulation and drying of pharmaceuticals

Pharmaceutical industries employ several process...

Continuous roller compactor for dry granulation of pharmaceuticals

When making tablets, pharmaceutical manufacturers ne...

Container blender for pharmaceuticals

Manufacturing pharmaceutical solids like tablets requires using a proper blender to b...

Single-use containment valves

From GMP and HSE perspective material transfer is critical for chemical and pharmaceutical for...

Big bag filling machine

Active pharmaceutical ingredients demand high handling standards to prevent cross-contamination. More...

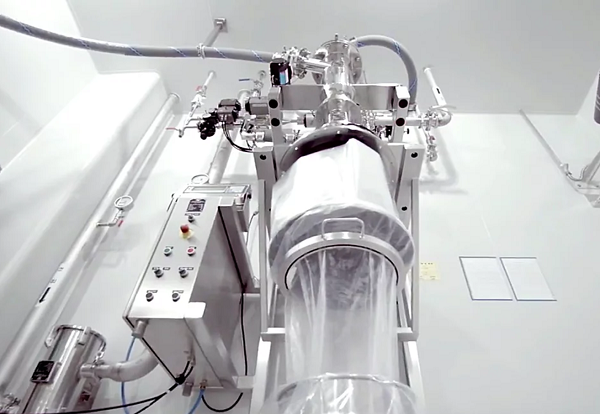

Disposable isolator

Pharmaceutical powders need to be contained in the strictest conditions. But handling powders and cleanin...

High containment micronizing isolator

Powder processing for chemical compounds demands product-specific micronizing solutio...

Filter dryer discharging isolator

Contained discharging is critical to the quality of filtration and drying processes. But ...

Contamination free filling system

Liners for powder handling across industries must prevent contamination of materials to c...

API containment isolator

Contamination is a major concern in powder handling, not least when processing pharmaceutical produc...

Big bag discharger

Big bags offer suitable material handling for powder products from pharma and food ingredients to bulk and...

Production scale jet mill

Large volume manufacturers demand the most out of their production process, including powder milli...

Jet mill micronizer

Small scale manufacturers that require effective micronization of powders for their process lines may nee...

Pilot scale jet mill

In a pilot scale level or preliminary study, all the production process steps have to satisfy the small ...

Laboratory jet mill

Manufacturing small quantities of high-value products requires efficient machines that can process these ...

Jet mill for clinical trials

R&D laboratories may need to reduce the size of powder particles in small quantities for cl...

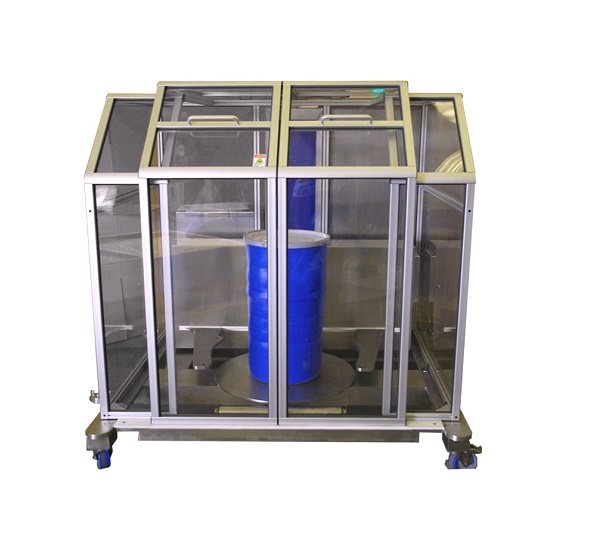

Drum filling system

Pharmaceutical and chemical products may be toxic or prone to contamination from environmental exposure. ...

Drum emptying system

Handling products from the pharmaceutical and chemical industries requires careful attention and extreme...

Small-scale laboratory dispersing machine

Developing and validating new processes requires reliable and highly versatile e...

Eccentric press for refill tablets

Hundreds of different refill tablets, of various shapes or sizes, are on the market toda...

Continuous centrifuge for lithium hydroxide

Lithium hydroxide, a lithium compound used in making lithium batteries, is ind...

Single-use containment valve

Safe transfer of liquids and hazardous powders into systems can be a challenge in pharma, bioph...

Metal detector for granulated products

Free-fall applications, such us flour, sugar, spices and other granulated or powdere...

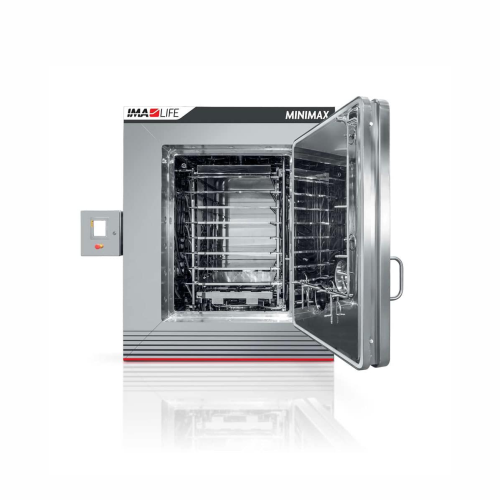

Laboratory scale active freeze dryer

The laboratory-scale active freeze-drying is used for dehydrating high-value products ...

Drum tipper

Many pharmaceutical processes require drums of powders or liquids to be fed from one part of the process to the ne...

Bin blender

Many pharmaceutical processes require the blending of powders or other granular ingredients, the mixing of settled...

Container lifter

Container handling in the pharmaceutical industry brings its own set of unique challenges. Traditional barrel...

Tumbler sieve for classifying and dedusting granular materials

For the classification of delicate granular material, scr...

Feeder with flexible wall hopper

The varying properties of dry powder products mean that specialized feeders are required fo...

Small feeder with flexible wall hopper

In many laboratory applications and production processes, smaller quantities of powd...

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

Spherical dryer

Drying vessels that are simple, reliable, and easy to maintain increases product quality and process efficienc...

Disposable tank liners

Manufacturers in the bioprocessing industries are increasingly turning to single use solutions for the...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

Hygienic automatic iris valve

In automated systems where controlled discharge of powders and bulk solids is required with a ...

Hygienic hand-operated iris valve

Hand-operated valves are required for the walls of clean rooms for glanding around cables...

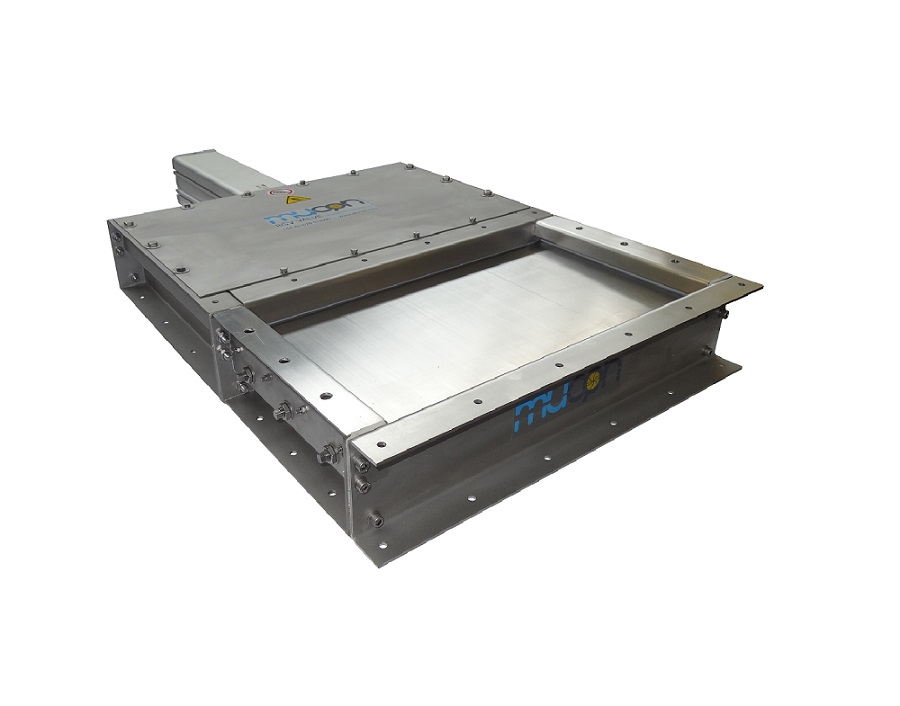

Slide gate valve

In the powder and bulk handling industries, in-line shut off valves are required to provide uninterrupted smo...

Roller gate valve

In large scale operations, modular and configurable valves are required to isolate and control dry powders,...

High containment split butterfly valve

Powder containment is the cornerstone of chemical and pharmaceutical manufacturing. ...

Downflow booth

Provides the highest levels of operator protection from potentially harmful airborne contaminants generated dur...

Inline batch mixer for solids and liquids

Several issues often arise when your process requires batch-wise mixing of powde...

Dust-free continuous homogenizing system

Producers in a wide variety of industries benefit from equipment that can continuo...

Laboratory dispersing machine for low-viscous masses

Laboratory mixers have not always been easy to work with. Getting a...

Agitator for medium viscosity media

Mixing fluids of medium viscosity for many production processes requires an agitator wi...

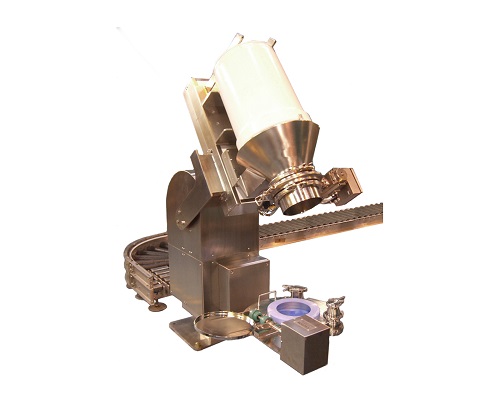

Flexible contained charging for split butterfly valves

Poly bottles with split butterfly valves are often used to transfe...

Crimping system

Flexible disposable containment systems in the form of specially designed plastic bags are an excellent choice...

Flexible contained drum transfer system

Transferring powders from drums to process equipment such as reactors or mills can ...

Compact strip packaging for solid products

Efficiently package a variety of solid pharmaceutical products with precision a...

Tablet elevator for pharmaceutical applications

Ideal for efficient transport and elevation of delicate pharmaceutical tab...

Small-scale freeze dryer for pharmaceutical applications

Optimize small-batch and pilot-scale lyophilization with advance...

Vacuum paddle dryer for active pharmaceutical ingredients

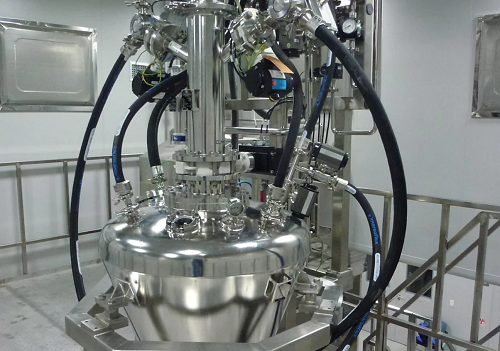

For precise moisture control and contamination-free conditions...

Integrated plenum tablet coater

Achieve consistent and high-quality coatings on tablets with advanced airflow management, ef...

Tablet coating system for laboratory development

Optimize your tablet formulation development with a versatile coating sys...

Pharmaceutical high-shear mixer granulator

Enhance your production efficiency with a high-shear mixer granulator, designed...

High-throughput aseptic isolator for syringes and vials filling

Streamline your aseptic filling process with a high-spee...

Tablet counting solution for pharmaceutical industry

Maximize dosing precision and reduce miscounts in high-speed pharmac...

Bench-top mixer and spheronizer for formulation development

Accelerate R&D success by seamlessly integrating mixing...

Tablet coating system for pharmaceuticals and supplements

Enhance tablet coating efficiency with flexible, replaceable p...

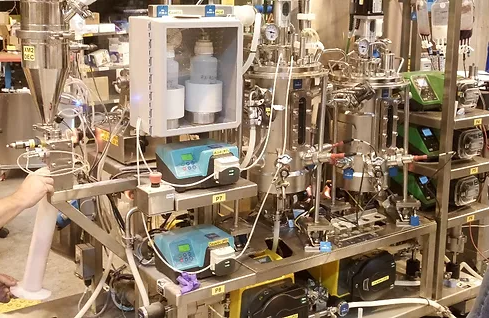

Purified water system for pharmaceutical industry

Ensure consistent purity and compliance in your production line with a ...

Drum decanting unit for high viscosity liquids

Efficiently decant high viscosity liquids like solvent-based paints and ess...

100l laboratory jacketed glass reactor

Optimize your batch processing with this 100L jacketed glass reactor, designed for p...

1200°c Pe/cvd furnace for high-temperature material synthesis

Enhance your material processing capabilities with precise...

Empty capsule sorting system for pharmaceutical manufacturing

Expedite your capsule production with a high-speed system ...

Tablet compression module for high containment applications

Quickly switch between tablet batches without compromising s...

Medium-volume rotary tablet press for pharmaceuticals

Optimize tablet production with high-throughput and rapid changeove...

Integrated small-scale granulation and drying system

Ensure precise granule size and moisture control for enhanced tablet...

Centrifugal separator for pharmaceutical extraction

Optimize your extraction process with precision centrifuging that enh...

Pharmaceutical isolator system for aseptic production

Ensure aseptic conditions and operator safety with a robust isolati...

Single screw feeders for granules

Optimize the feeding of well-flowing granules with precision and consistency—key for main...

Calendering solution for laboratory production of films, tapes, and tablets

When rapid production of high-quality film...

Cooling conveyor belt for extrudates and granules

Efficiently cool and convey extrudates and granules with precise temper...

Pharmaceutical twin-screw extruder

Optimize your pharmaceutical production with high-speed continuous extrusion that ensure...

Precision laser drilling for osmotic controlled release tablets

Enhance tablet precision and control drug release with h...

Industrial sieving machine for pharmaceuticals

One of the physical attributes that granular pharmaceutical products must h...

High containment big bag discharge docking system

The discharge of materials demands strict containment, particularly in ...

Pharmaceutical data management software

A typical pharmaceutical production handles numerous work flow activities like mana...

Automatic centrifuge for lithium carbonate

The battery industry requires high purity components. To obtain more than 99.5%...

Particle analysation monitor

Products like granules, tablets and capsules require inspection at numerous steps in the produc...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

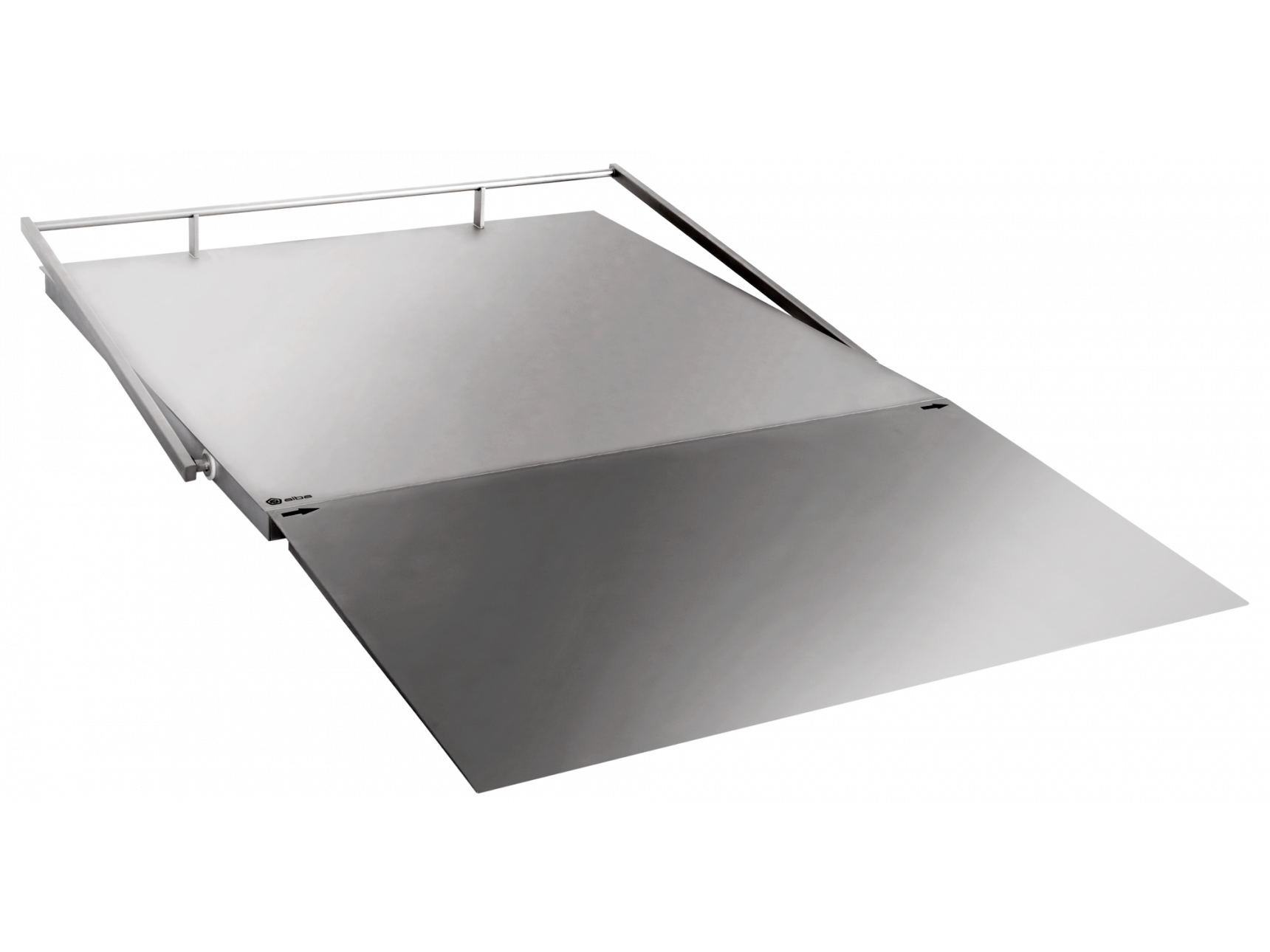

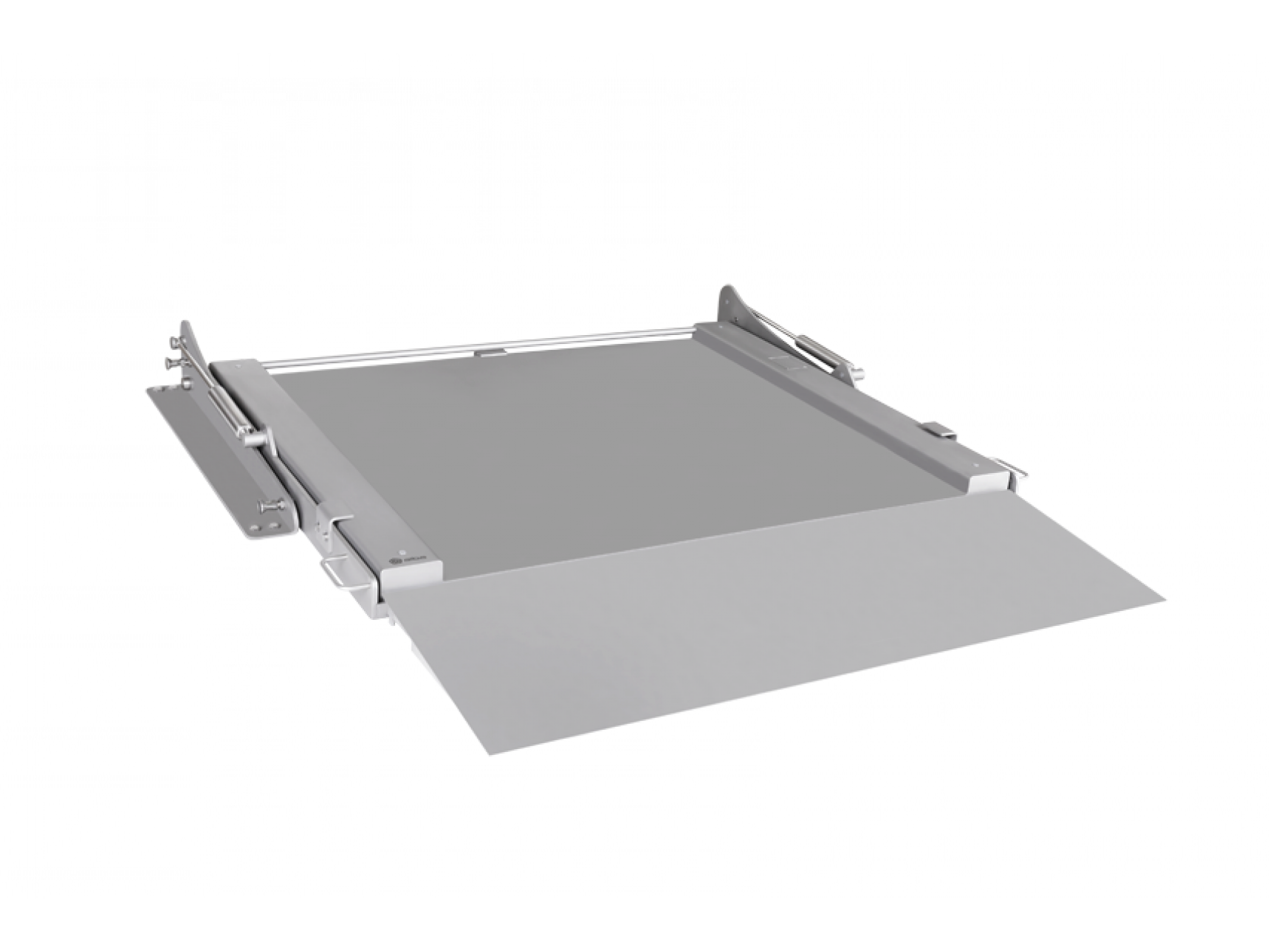

Hygienic floor scale

The food and pharmaceutical industries require maintaining high levels of sanitations as well as logisti...

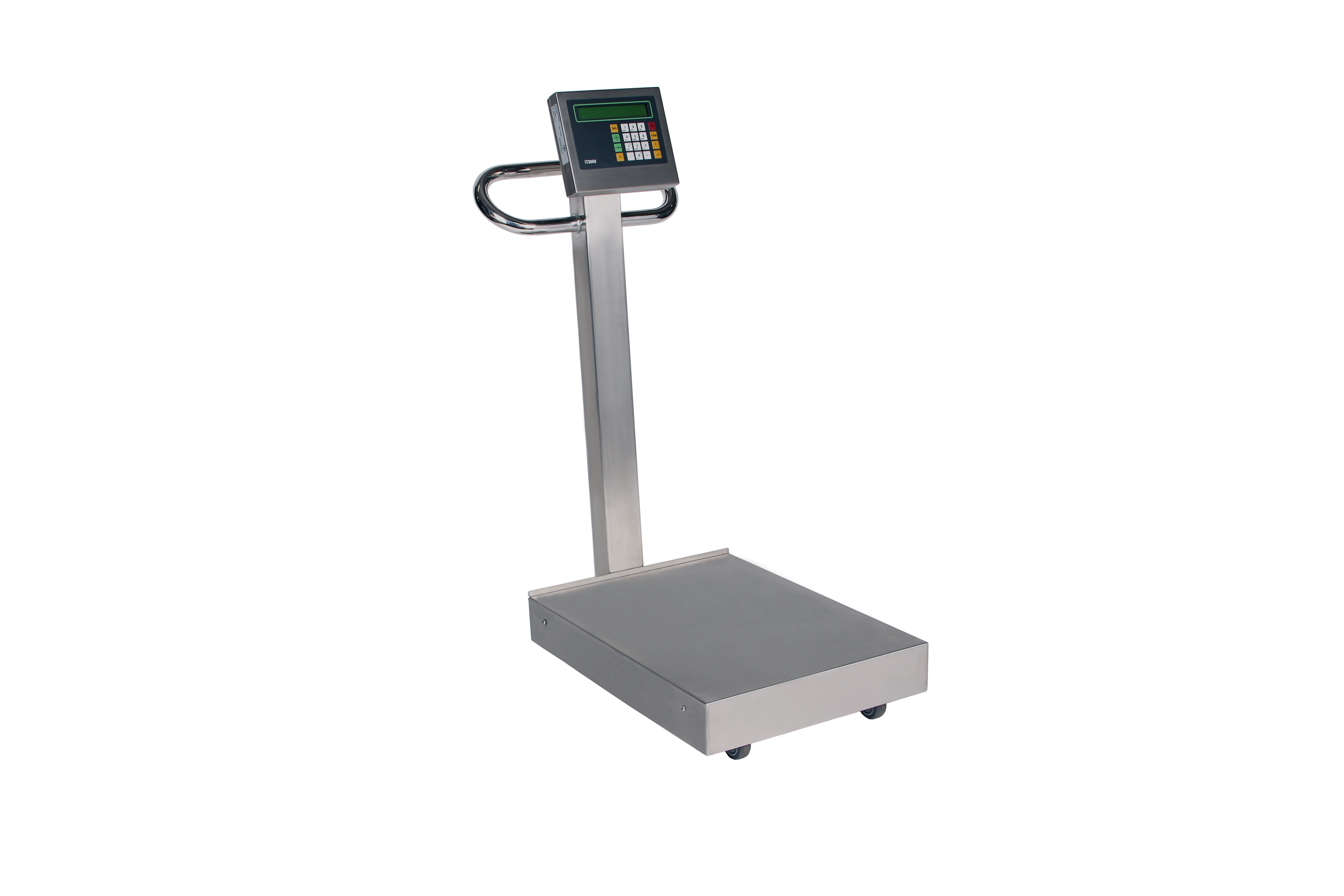

Hygienic mobile scale

Having a reliable and accurate weighing and measuring solution is absolutely essential, especially in t...

High containment closing system

Pharma and biopharma laboratories need fast effective solutions for tightly sealing bags for...

High containment sampler

Drawing a sample for evaluation from a running process is not a simple task, especially when dealing...

Pharmaceutical pure steam generator

Dry, saturated steam can be used to sterilise pharmaceutical manufacturing equipment, a...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Flexible containment docking solution

When sampling or transferring hazardous substances and sensitive bulk goods, a dust-t...

Flexible containment zip

Transfer of sensitive and toxic bulk goods across process units requires specialist handling to prev...

Drum conditioner

Many pharmaceutical production processes involve the use of products that have naturally hardened within thei...

Pharmaceutical container lifter

Moving larger or heavier containers from height is out of the scope for standard handling eq...

Vacuum sack lifter

In the production of pharmaceuticals and other high-hygiene environments, manual handling of inputs or int...

Mobile drum lifter

The production of pharmaceuticals and other hygienic products often requires the handling of large and bul...

GMP Jib crane

Vacuum manual handling systems are the ideal way of quickly and safely moving small to medium sized loads in all...

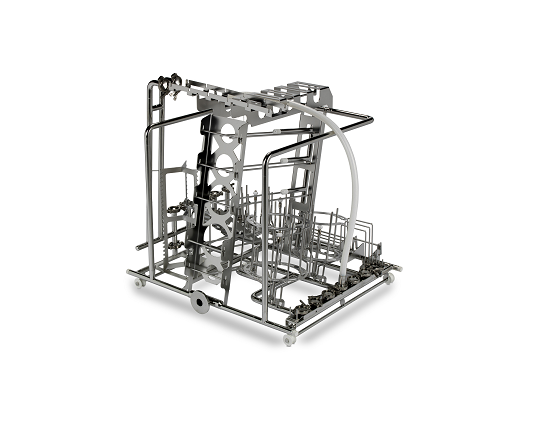

Loading basket for GMP washer

To ensure perfect cleaning of contact parts they must be placed in the GMP washer in such a wa...

Bulk chamber washer

The production of cosmetics, nutraceuticals or unregulated pharmaceuticals often requires the cleaning an...

Entry-level chamber washer

When cleaning smaller products contacting filling or compressing components used in the productio...

Colloid mill

For creating extremely fine emulsions and high quality dispersions a high pressure homogenizer is often chosen. ...

High-pressure homogenizer

When processes call for homogenized emulsions with extremely fine particle sizes the traditional t...

Checkweigher for sachets and sticks

The checkweighers for multiple lanes have a 1.5 times faster response speed and 2 times...

Microencapsulation system for your drug delivery system

Whether you want to improve the stability of nutrients, protect a...

Centrifugal disc filter

The pharmaceutical and bioprocess industries need filtration processes of particularly high quality t...

Transfer system for high-containment environments

A high-performance transfer port system that combines ultimate safety, ...

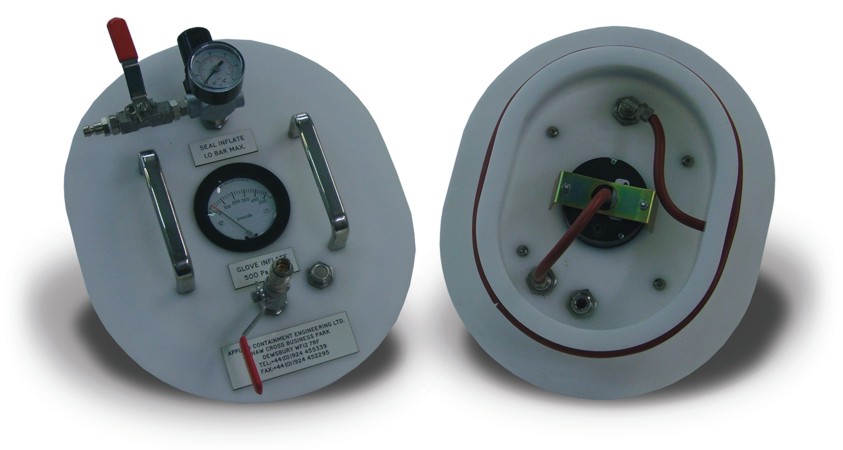

Half-suit tester

Designed to allow operators to perform sterility testing in an aseptic environment providing assurance of mat...

Glove tester

Testing device of the containment capability of gloves, which is as important as the other parts of the integrate...

High containment segment ball valve

Valves fitted in blenders and dryers can have dead spaces that prevent complete process...

Removable GMP compliant connections for tubing

Tubing frameworks can have rough welding joints, corners and sharp angles t...

Negative pressure isolator

Used for products biologically hazardous, that also require minimized cross contamination.

Corundum disk mill

Wet milling and grinding of viscous liquids or pastes containing solid particles such as peanut butter,mus...

Vertical laminar flow cabinet

HEPA filtered vertical laminar airflow (down flow) creates an ISO 14644-1 (Class 5) work area ...

Horizontal laminar flow benches

HEPA filtered horizontal laminar airflow (crossflow) creates an ISO 14644-1 (Class 5) work a...

Compact horizontal laminar flow bench

HEPA filtered horizontal laminar airflow (cross-flow) creates an optimized free space...

Microbiological safety cabinet class II

This handy device offers the most advanced features in product-operator protection ...

Biosafety cabinet class II for cytotoxic medicines

For the manipulation of hazardous substances utilized during the prepa...

Positive pressure isolator

Ideal for products which have no biological risk but require high sterile conditions.

Biological safety cabinet class III

Specially designed for the handling of microbiological agents, when working with indige...

Hygienic floor scale with lifting device

The food and pharmaceutical industries require maintaining high levels of sanitati...

Dispersing machine for emulsions and suspensions

Equipment operating under the rotor/stator principal is often employed wh...

Economic dispersing machine for emulsions and suspensions

For products of medium viscosity and relatively consistent par...

Dispersing machine for very fine emulsions and suspensions

For continuous high performance mixing of solid and liquid ra...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...

Cone mill machine

When your raw materials include agglomorated suspensions of grainy or crystalline solids and your process n...

Continuous homogenizing system

Certain mixing tasks present unique challenges and manufacturers need equipment that is speci...

High accuracy homogenizing system

When extremely high accuracy is required in your recipe or formulation traditional mixing...

Horizontal kneader

For high viscosity products, better results and reduced process times can be achieved with kneading type r...

Vertical kneader

Production of highly viscous products with high solid content often benefits from kneading processes rather t...

Continuous kneader

Effective mixing of highly viscous products with extremely high solids content can be difficult and the re...

Batch dispersing machine

Equipment operating under the rotor/stator principal is often employed when more traditional methods...

Batch dispersing machine for abrasive products

For mixing and dispersing tasks that cannot be completed by conventional st...

Batch dispersing machine for bottom entry into vessels

When your process requires high performance mixing or dispersion b...

Cost-effective homogenizing and emulsifying system

Manufacturers of cosmetic products need mixing equipment that is capab...

Dilution system for two or more liquids in one pass

Onsite dilution of liquid process ingredients has historically been a...

Pilot dispersing machine for testing and scale-up

Innovators in process development need laboratory equipment that helps ...

In-line laboratory dispersing machine

Innovators in a wide variety of industries need laboratory equipment on which process...

Jet flow agitator for high-viscosity media

Processes including homogenization, dispersing, suspension, emulsification and ...

Agitator for low viscosity media

Reliably agitating fluids in open or pressure-less vessels in a laboratory or small scale p...

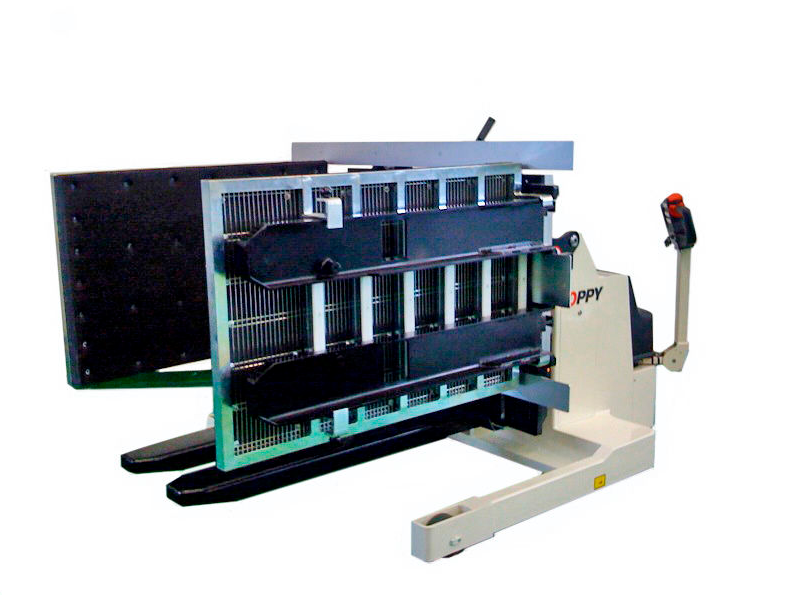

Mobile pallet turner

Turning your pallet may allow for more effective pallet changing than the conventional lifting and grabb...

In-line pallet changer

When you need to transfer load from one pallet to another without tilting or turning, then selecting t...

Non-tilting pallet changer

Stable vertical lifting of the load from the pallet to enable EPAL or industrial pallet exchange.

V-shaped pallet changer

If you are looking for a sturdy pallet changing solution, a stationary V-shaped pallet changer can be...

Pallet changer floor level

For transferring goods from wooden pallets to plastic pallets, or vice-versa, this Pallet changer...

Pallet changer

For turning loads and exchanging them on pallets, here is a stationary pallet changer that will load and unload...

Mobile pallet changer without turning

If you are looking to change the pallet without turning the load, through a lateral p...

Versatile mobile pallet turner

Here is the versatile mobile pallet turner that completes the typical features of all mobile ...

Mobile pallet turner for higher stacks

When you need to opt a pallet changer that is capable of lifting and turning loads a...

Aseptic barrier systems

Designed for sterile product and Potent API’s either with low or high OEL requirements.

Restricted-access barrier systems

Create a physical barrier between the operator and the product. More flexible than an iso...

Sterility test isolators

Designed to avoid this risk and protect the product from both the process and externally generated f...

Horizontal chemical scraper centrifuge

For slurries difficult to discharge, a scraper can improve process reliability, effi...

Horizontal pharmaceutical scraper centrifuge

For slurries difficult to discharge, a scraper can improve process reliabilit...

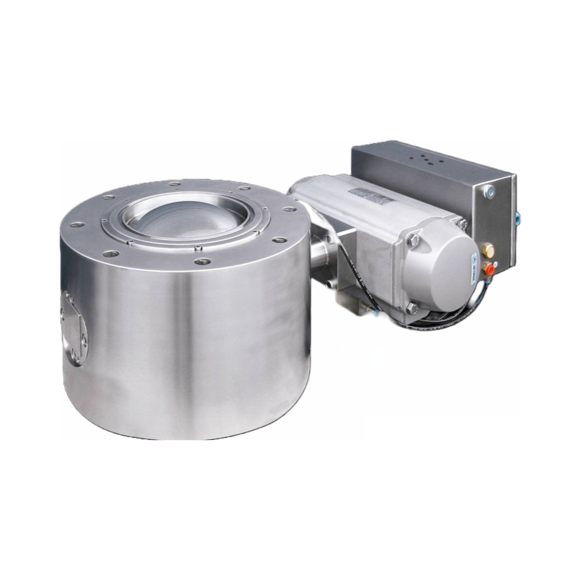

Isolator centrifuge

For transferring highly active pharmaceutical ingredients (HAPI) without contamination from the isolator ...

Mobile pilot plant centrifuge

The system is perfectly suited for pilot plants as well as small-quantity productions in the f...

Vertical top discharge centrifuge

Discharge solids vertically upward through manual action, optionally using a filter bag o...

Vertical peeler centrifuge

A vertical peeler centrifuge is used to separate solids, usually to separate fine particles from ...

Vertical scraper centrifuges

Vertical Bottom discharge Centrifuges work discontinuously, discharging the solids to the botto...

Pusher centrifuge

Pusher centrifuges are continuously operating filter centrifuges and can have several basket stages dependi...

Checkweigher for stand-up pouches

When working with several lines of stand-up pouches, you can benefit from controlling the...