Centrifugal separator for pharmaceutical extraction

Optimize your extraction process with precision centrifuging that enhances product purity and efficiency, ensuring high-quality outputs while reducing waste.

Separates and Clarifies Pharmaceutical and Chemical Mixtures

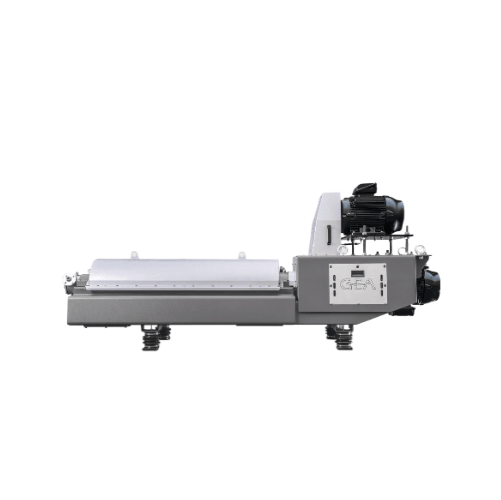

The Decanter pharmMaster from GEA is a purpose-engineered centrifuge designed for the rigorous demands of pharmaceutical and chemical extraction processes. Specializing in the separation and clarification of complex mixtures, it efficiently handles active pharmaceutical ingredients, medicinal plant extracts, and chemical intermediates. This decanter utilizes a solid-wall bowl with a cylindrical and conical section, enabling effective dewatering and clarification in high solids content environments. Featuring GEA’s summation-drive with intelligent kinematics, it achieves high differential speeds and torques necessary for processing substantial solid capacities while reducing energy consumption via a variable-speed motor. Constructed from high-alloyed stainless steels and compliant with ATEX standards, the device offers robust corrosion resistance and explosion protection, ensuring safe operation with volatile compounds. With automation capabilities and remote monitoring options, the pharmMaster seamlessly integrates into continuous production lines, maintaining optimal performance and reliability. A CIP system enables straightforward cleaning, minimizing downtime and ensuring contamination-free operations, while customization options, including material selections and engineering support, cater to specific production requirements.

Benefits

- Enhances production efficiency by handling large volumes with continuous operation.

- Reduces energy costs with a variable-speed motor and optimized kinematics.

- Ensures safety in explosive environments through ATEX-compliant design.

- Offers corrosion resistance with all contact parts made from high-alloyed stainless steels.

- Minimizes downtime with easy cleaning via an integrated CIP system.

- Applications

- Chemicals, Pharma extraction, Pharmaceuticals

- End products

- Active pharmaceutical ingredients (apis), Medicinal plant extracts, Chemical intermediates

- Steps before

- Comminution, Grinding, Mixing with extraction agent

- Steps after

- Clarification, Dewatering, Centrifugal extraction

- Input ingredients

- extraction products, extraction agent, comminuted material, suspension

- Output ingredients

- solids discharge, extraction residue, extract

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Automation

- PLC-controlled

- Material of Construction

- High-alloyed stainless steels

- Differential Speed

- High differential speeds and torques

- Cleaning Method

- Chemical cleaning after separation

- Design Standard

- ATEX compliant

- Suspension Inlet

- Axially arranged

- Bowl Design

- Solid-wall with cylindrical and conical sections

- Gas Displacement

- Inert gas blanketing

- Solids Discharge

- Conveyed to conical end

- Extraction Liquid Discharge

- Discharged via a centripetal pump

- Working mechanism

- Solid-liquid extraction

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP / Manual

- Automation level

- PLC-controlled

- Explosion Protection

- ATEX compliant, gas-tight

- Stainless Steel Compatibility

- High-alloyed stainless steels

- Gasket Material

- NBR, FKM or EPDM

- Corrosive Resistance

- Yes (suitable for acidic environments)

- Inert Gas Blanketing

- Prevents corrosion and oxidation

- Shape of the bowl

- Cylindrical and conical sections

- Discharge method

- Centripetal pump

- Material of construction

- High-alloyed stainless steels

- Feed method

- Axial inlet

- Control System

- Standardized or tailor-made automation solutions

- Drive Type

- GEA summation-drive with variable speed motor

- Inert Gas Handling

- ATEX-compliant gas-tight decanter

- Material of Construction

- High-alloyed stainless steels

- Gasket Material

- NBR, FKM, EPDMChemical

- Explosion Protection

- ATEX certified