Pharmaceutical sieving equipment for high hygiene standards

Ensure the purity of pharmaceutical powders and granulates with precision sieving technology designed for high hygiene standards, optimizing your production line by effectively removing contaminants and maintaining uniform particle size distribution.

Separates and Homogenizes Pharmaceutical Powders and Granules

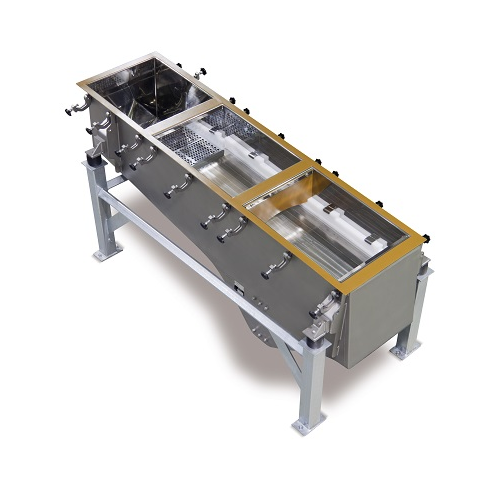

The Pharma Siebmaschine from SPALECK is a highly efficient vibratory sieving machine specifically designed for the pharmaceutical industry. Utilizing precision vibration technology, it expertly separates, de-dusts, and homogenizes powders and granules, ensuring optimal ingredient consistency for end products such as tablets, gel capsules, and protein supplements.

This equipment features a robust stainless steel construction, meeting the industry’s demanding hygiene standards, and is ATEX and GMP compliant. With a throughput tailored to your production needs, it supports continuous, batch, and high-speed operations. The integrated Cleaning in Place (CIP) system guarantees easy maintenance and minimized downtime, facilitating seamless integration into existing production lines.

SPALECK’s Pharma Siebmaschine is PLC-controlled, offering compatibility with advanced remote monitoring systems, ensuring efficient operation and superior process control. Available customization options, such as rotor speed and chamber configurations, coupled with extensive engineering support, make it adaptable to unique production requirements.

Benefits

- Ensures product purity and compliance with stringent industry standards.

- Minimizes contamination risk with seamless integration and efficient CIP system.

- Adapts to various production scales with customizable configurations.

- Enhances product consistency through precise de-dusting and homogenization.

- Increases operational efficiency with PLC-controlled, high-speed operation.

- Applications

- Ingredients, Agglomerates, Pellets, Pharmaceutical powder, Granulates, Pills, Pharmaceutical products, Pharmaceuticals

- End products

- Granular vitamin mixes, Active pharmaceutical ingredients (apis), Tablets, Gel capsules, Pharmaceutical ingredient compounds, Vitamin powders, Coated pellets, Protein supplements, Effervescent tablets, Injectable powders

- Steps before

- Purification, Grinding, Blending, Mixing, Pre-screening

- Steps after

- Packaging, Sterilization, Coating, Inspection, Tablet Pressing

- Input ingredients

- pharmazeutische Pulver, Arzneimittel, Pulver, Pellets, Pillen, Granulate, Agglomerate

- Output ingredients

- gereinigte Pharmazeutika, arzneimittelbestandteile, fraktionierte Produkte, homogenisierte Zutaten, staubfreie Produkte, präzise Korngrößen

- Market info

- Spaleck is known for its expertise in designing and manufacturing innovative screening, separation, and conveying technology, particularly for recycling and bulk materials industries, and is reputed for high-quality, durable equipment tailored to customer specifications globally.

- Material

- Stainless Steel

- Compliance Standards

- GMP, ATEX

- Automation

- Manual / Auto

- Cleaning Method

- CIP

- Hygienic Design

- Polished Surface with Low Roughness

- Application

- Pharmaceutical Powders, Pellets

- Operation

- Batch / Continuous

- Reproducibility

- High Precision

- Particle Size Reduction

- Precise Distribution

- Load Capacity

- Variable

- Sieving Accuracy

- High Separation Efficiency

- Cleaning Integration

- Optimal Cleaning Options

- Heat Generation

- Low

- Dust Control

- Dust-Free Execution

- Mobile Execution

- Optional

- Batch vs. continuous operation

- Batch

- CIP/SIP

- CIP optimized

- Cleaning method

- CIP (Cleaning in Place)

- Automation level

- Highly automated

- Energy efficiency

- High

- Changeover time

- Reduced due to ComfortLINE design

- Hygienic design

- Stainless steel with low surface roughness

- Contaminant resistance

- Prevents entry of foreign particles

- Corrosion resistance

- Stainless steel construction

- Temperature resistance

- -40°C to +85°C

- Cleanability

- Optimized for CIP (Cleaning in Place)

- Compact footprint

- Designed for easy integration into existing processes

- Material

- Stainless steel with polished finish for hygiene

- Machine Footprint

- Customizable based on production needs

- Discharge method

- Customizable with options such as feed, transport, and dosing troughs