Pellet dedusting elutriators

Achieve superior purity in your production line by effectively removing dust and streamers with advanced dedusting technology, streamlining operations and enhancing product quality with precision separation solutions.

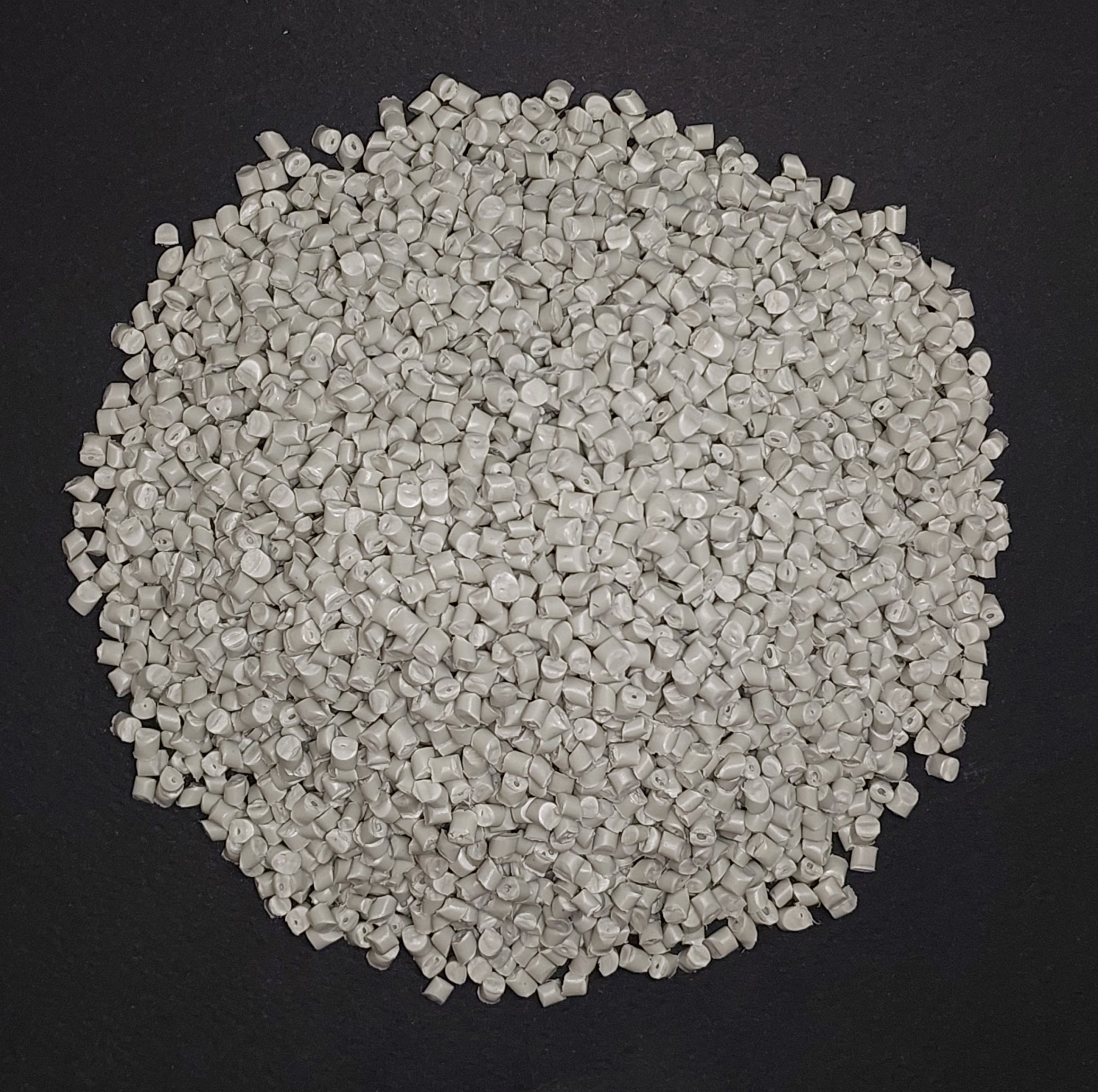

Separates Dust and Fibers from Granular Products

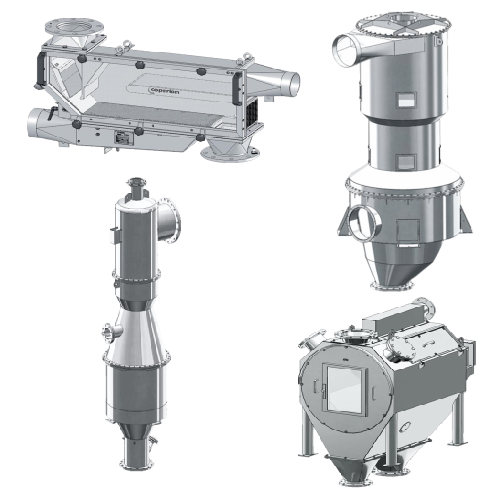

The Horizontal Fluidbed Separator HFS by Coperion is a sophisticated solution for granular product cleaning, designed to efficiently remove dust and fibers from materials such as polyethylene pellets, toner particles, and dairy powder blends. Its working principle utilizes a fluidized bed for gentle yet thorough separation, ideal for industries like plastics, chemicals, food, and pet food. With a processing capacity of up to 40 tons per hour, the HFS offers a compact design suitable for space-constrained facilities. Integration is straightforward, thanks to its pneumatic feeding system and adaptable configuration. The unit is crafted from durable materials, providing resistance to abrasion and corrosion, ensuring long-term reliability in demanding production environments. Additionally, this separator supports easy cleaning and maintenance, featuring an accessible design that minimizes downtime. Coperion offers customization and engineering support to tailor the HFS to your specific operational needs.

Benefits

- Enhances product purity by effectively removing fine dust and fibers.

- Optimizes production efficiency with a throughput capacity of up to 40 tons per hour.

- Compact design saves space while maintaining efficient cleaning performance.

- Reduces operational costs with minimal maintenance requirements.

- Supports diverse applications across plastics, chemicals, food, and pet food industries.

- Applications

- Chemicals, Food, Pet food, Plastics, Minerals

- End products

- Polyethylene pellets, Polypropylene granules, Toner particles, Catalyst carriers, Dairy powder blends, Powder coating materials, Fish feed pellets, Cement powders, Calcium carbonate granules, Pet food kibble, Pvc powder, Snack pellets

- Steps before

- Purification, Grinding, Bulk Material Handling

- Steps after

- Dedusting, Pelletizing, Packing, Product Transfer

- Input ingredients

- granular products, pellets, dust, streamers, soft and brittle granular products, abrasive products

- Output ingredients

- cleaned granular products, separated dust, separated streamers, purified bulk materials

- Market info

- Coperion is known for its expertise in manufacturing industrial compounding and extrusion equipment, bulk materials handling systems, and services for various industries, such as plastics, chemicals, and food processing, with a strong reputation for innovative engineering solutions and customer support.

- Separating efficiency

- Optimized for high efficiency

- Capacity

- Up to 120 t/h (Diverting Counter-flow Elutriator)

- Capacity

- Up to 100 t/h (Gravity Rotation Separator)

- Capacity

- Up to 40 t/h (Horizontal Fluidbed Separator)

- Cleaning stages

- 1 or 3 (depending on separator type)

- Cleaning method

- Automatic (for Drum Sieve Machine)

- Design height

- From 650 mm (Horizontal Fluidbed Separator)

- Feeding type

- Pneumatic or gravimetric

- Pneumatic separation

- Yes (Horizontal Fluidbed Separator)

- Gas consumption

- Optimized (Diverting Counter-flow Elutriator)

- Separation efficiency

- High

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- Fully automatic sieve cleaning

- Batch vs. continuous operation

- Continuous

- Airflow control

- Pneumatic / gravimetric feeding

- Throughput capacity

- Up to 120 t/h

- Abrasion resistance

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Heights from 650 mm

- Feed method

- Pneumatic or gravimetric from a hopper

- Discharge method

- Base, silo top, or between silo and tank car installation options

- Gravity Rotation Separator

- Capacities of up to 100 t/h

- Horizontal Fluidbed Separator

- Up to 40 t/h

- Drum Sieve

- Compact, service-friendly unit

- Control panel type

- PLC-controlled / Manual

- Customization type

- Elutriator configuration

- Compact footprint

- Yes / No

- Integration possibilities

- Pneumatic / Gravimetric feed

- Installation Type

- Base / Silo top / In-line