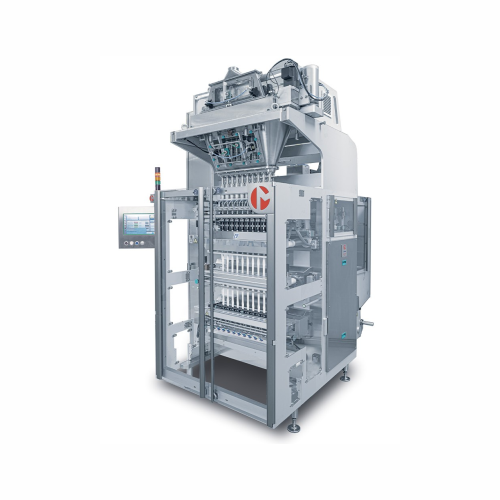

Stickpack filling and closing system for pharmaceutical powders

Achieve precise dosing and secure packaging for pharmaceutical powders and granules with an optimized stickpack system designed for high-speed operation, ensuring product consistency and reducing contamination risks in your production line.

Forms, Fills, and Seals Stickpacks

The MT SERIES Stickpack Filling and Closing Machine from Marchesini Group excels at forming, filling, and sealing stickpacks for pharmaceutical and nutraceutical applications. This equipment stands out with its ability to efficiently package powders and granules like paracetamol, antacid, and vitamin supplements, ensuring precise dosing with a 10-lane Auger Filler Dosing Unit. Each auger lane operates independently with brushless motors to maintain dosing accuracy and allows self-correction when integrated with a checkweigher. The machine’s modular design facilitates quick maintenance and cleaning, aided by the Group of Fast Release for easy disassembly. The MT SERIES operates at high speeds, reaching up to 65 cycles per minute, accommodating stickpack widths from 18 to 60mm, and lengths between 60 to 160mm. It supports seamless integration into production lines with minimal hard-to-reach points for enhanced accessibility. Built to meet stringent pharmaceutical standards, the machine offers options for different material builds for optimal product compatibility and longevity.

Benefits

- Enhances operational efficiency with high-speed performance of up to 65 cycles per minute.

- Ensures precise product dosing, improving quality control and reducing waste.

- Facilitates quick changeovers and maintenance due to its ergonomic design.

- Minimizes cleaning time with easy access to all components, enhancing uptime.

- Complies with pharmaceutical industry standards, ensuring reliable operation in regulated environments.

- Applications

- Pharmaceutical powder, Granules

- End products

- Vitamin c granules, Antibiotic powder, Calcium supplement granules, Antacid granules, Paracetamol powder

- Steps before

- Preparation of powders, Granulation, Material handling

- Steps after

- Quality inspection, Packaging, Cartoning

- Input ingredients

- flexible heat-sealable packaging material, pharmaceutical dry products, powder, granules

- Output ingredients

- stick-packs, packaged products

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Stickpack Width

- 18 mm (0.70”) to 60 mm (2.36”)

- Stickpack Length

- 60 mm (2.36”) to 160 mm (6.29”)

- Output Cycles/minute

- Up to 65

- Reel Outer Diameter

- 600 mm (23.6”)

- Dosing Unit

- Auger Filler, 10 lanes

- Automation

- Brushless motor for each lane

- Motion Type

- Intermittent

- Material

- Flexible heat-sealable packaging material

- Working mechanism

- Intermittent motion

- Automation level

- Brushless motor-driven

- Changeover mechanism

- Group of fast release

- Batch vs. continuous operation

- Batch

- Cleaning method

- Easy access for cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Abrasiveness

- Yes/No

- Heat sensitivity

- Yes/No

- Bulk density

- 0.5–2.5 g/cm³

- Particle size

- 50–1000 µm

- Viscosity

- Low/Medium/High

- Container size

- 18–60 mm width

- Container length

- 60–160 mm

- Stickpack width

- min. 18 mm, max. 60 mm

- Stickpack length

- 60 to 160 mm

- Reel outer diameter

- 600 mm

- Dosing unit type

- Auger Filler

- Number of lanes

- 10 lanes

- Motor type

- Brushless motor

- Feedback system

- Checkweigher Feedback packet correction

- Machine disassembly

- Fast Release group

- Ease of access

- Minimal Hard To Reach Points (HTRP)