Commercial blister filling solution for dry powder

Efficiently fill and seal blister packs with precision, ensuring consistent dosage and product integrity for pharmaceutical powders and medical devices. Ideal for mid-speed operations seeking to enhance production line throughput without compromising quality or safety.

Forms, Fills, Seals, Cuts, and Inspects Blisters

The MSP Blister Filling Machine from Harro Höfliger represents a robust solution for pharmaceutical and medical device manufacturing, offering precise control over blister forming, filling, and sealing processes. Utilizing either drum or membrane dosing, it ensures accurate micro-dosing of powders. Ideal for producing diverse end-products such as aluminum blister strips for inhalers, aseptic blister packs, and transdermal patches, it delivers extensive application versatility. The MSP’s drum dosing achieves outputs of up to 576 fill volumes per minute, while membrane dosing reaches 2400. Its compact design integrates seamlessly into production lines, complemented by downstream assembly and packaging equipment. With integrated barrier technology and X-ray inspection systems, it promotes both operator safety and product quality, fully compliant with GMP and FDA standards. The machine’s ergonomic design allows easy operation and maintenance, featuring a range of customizable options to meet specific production needs.

Benefits

- Enhances production efficiency with high-speed filling capabilities.

- Ensures operator safety and product integrity with integrated containment systems.

- Minimizes wastage through precise micro-dosing technology.

- Facilitates quick production scaling with compact, easy-to-integrate design.

- Provides complete quality assurance with in-line X-ray inspection.

- Applications

- Continence care, Diagnostic products, Inhalation products, Transdermal, Pharmaceutical powder, Skin care, Microneedles, Surgical sutures, Pharmaceutical device assembly, Oral delivery systems, Ostomy, Medical, Wound, Eye care

- End products

- Pre-dosed microneedle patches, Blister packaging for oral pharmaceuticals, Eye care dropper blisters, Aluminum blister strips for inhalers, Aseptic blister packs for pharmaceuticals, Transdermal patch blisters, Medical diagnostic blister kits, Sterile suture packets, Blister packs for wound care ointments, Micro-dosed dry powder blister packs

- Steps before

- Web processing, Mass control, Production of suture material

- Steps after

- Product assembly, Packaging, Quality control, Sterilization

- Input ingredients

- dry powder, blister webs

- Output ingredients

- aluminum blister strips for inhalers, filled blister cavities, blister strips

- Market info

- Harro Hoefliger is known for its expertise in manufacturing custom, engineered-to-order packaging and production equipment, particularly for the pharmaceutical, healthcare, consumer goods, and chemical industries, with a reputation for precision, innovation, and quality engineering solutions.

- Blister Filling Speed

- Up to 2400 blister cups/min

- Drum Dosing Fill Volumes

- 576 Fill volumes/min (24 cycles/min)

- Membrane Dosing Fill Volumes

- 2400 Fill volumes/min (15 cycles/min)

- Web Width

- 200 mm

- Output

- Up to 30 strips/min (blister strips with 60 cups)

- Dosing Type

- Drum dosing / Membrane dosing

- Micro-dosing

- Yes

- Automated Cutting

- Yes

- X-Ray Inspection

- Destruction-free inspection of weights

- Compact Design

- Minimal set-up space

- Working mechanism

- Blister forming, filling, and sealing

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Inline Continuous

- Multiple location filling

- Drum dosing or membrane dosing

- Inspection and quality control

- X-ray integreated for weight inspection

- Changeover time

- Easy operation and maintenance

- Cleaning method

- Incorporates containment systems

- Production rate

- Up to 2400 blister cups/min

- Accessibility

- Separate production area

- Compact design

- Minimal set-up space

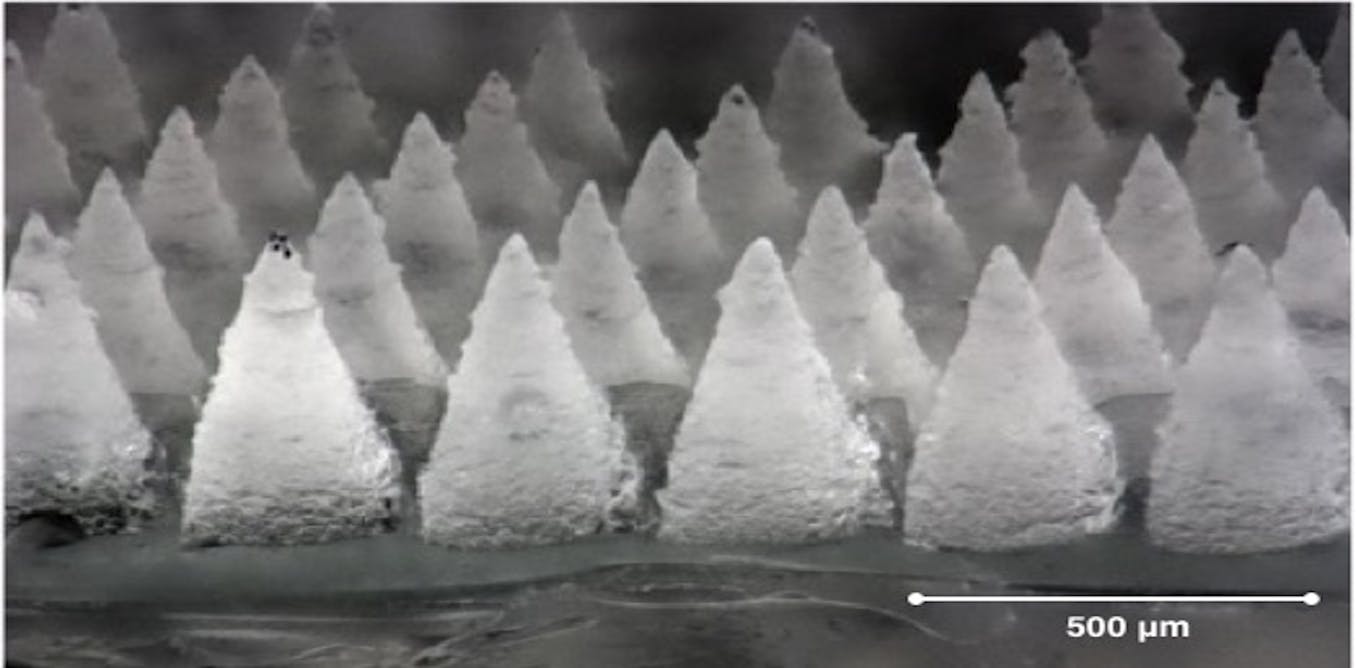

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Blister Filling Method

- Drum or Membrane Dosing

- Control Panel Type

- Easy operation

- Compact Design

- Minimal set-up space

- Control Panel Type

- Easy operation and maintenance

- Dosing Method

- Drum dosing / Membrane dosing

- Integration Features

- Integrated containment for operator protection

- Accessibility

- Separate production area with good accessibility

- Filling Area Design

- Multiple locations with high output