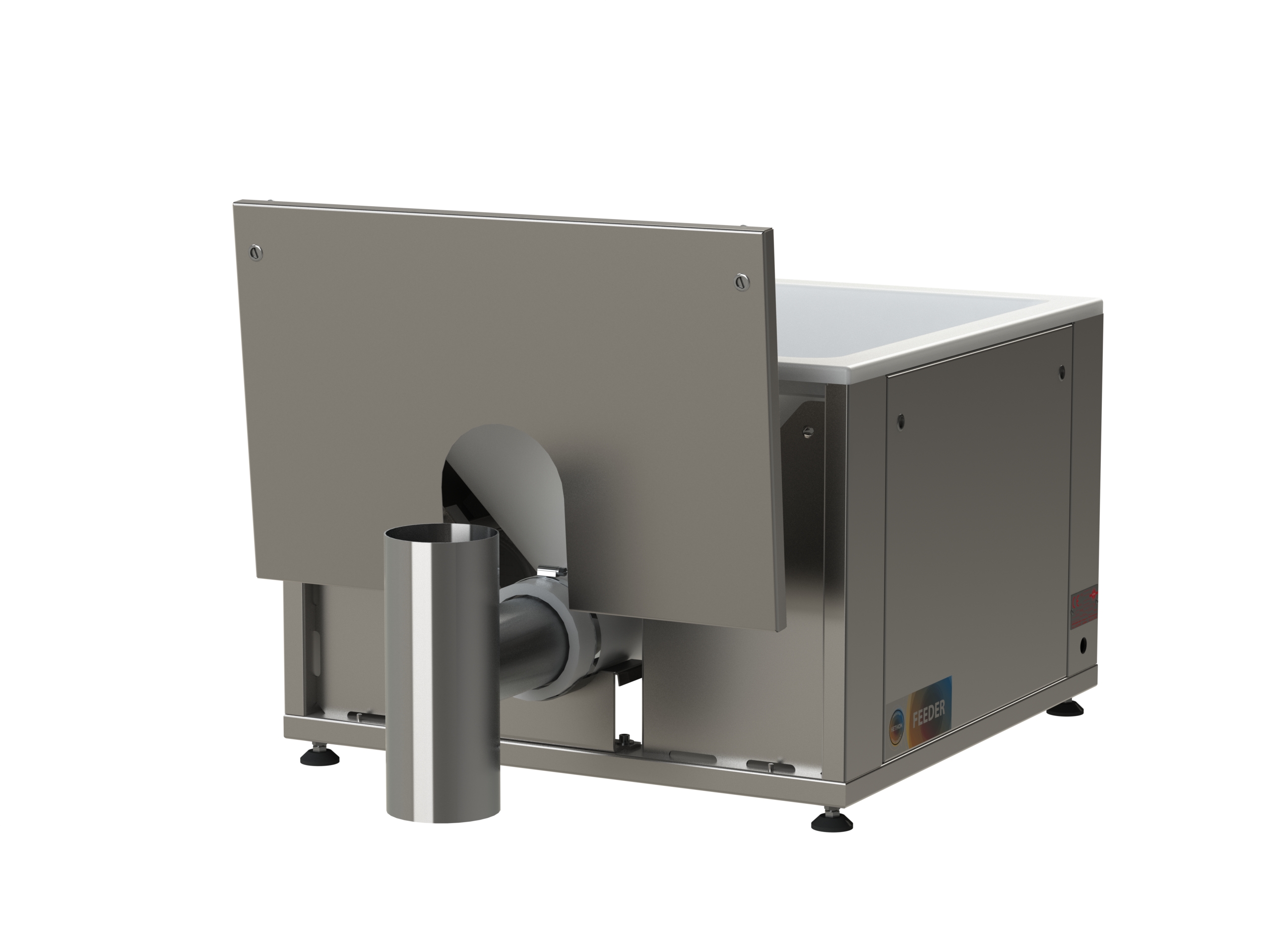

Feeder with flexible wall hopper

The varying properties of dry powder products mean that specialized feeders are required for dispensing them into the feed screw. Bad-flowing and compacting type powders can be damaged by internal agitation which causes bridging and ratholing of the product.

Accurately dose any dry substance without damage

The walls of all Hethon feeders are massaged with paddles from the outside to keep the powder moving without being damaged by stirring arms or internal agitators. This ensures efficient filling of the feed screw for optimum volumetric performance.

The capacity is controlled by frequency inverters for volumetric machines and for continuous or batch-based gravimetric dosing, an advanced weight control system is used.

The Hethon range of feeder models 40, 50, 60, 70, and 80 are available with a standard, FDA, antistatic, or chlorine resistant flexible hopper and can handle capacities anywhere from 150 to 32,000 liters per hour.

Hethon feeders have applications in the ceramic, chemical, environmental, food, paint, pharmaceutical, plastic, and rubber industries.

Benefits

- A solution for any powder dosing application

- No internal agitation which can cause a material degradation

- Very easy and fast to clean

- Low power consumption and long service life

- Atex zone 21 Certificated