Single-use containment valves

From GMP and HSE perspective material transfer is critical for chemical and pharmaceutical formulations. Risky substances, such as high-potency API, cadmium in batteries or other substances increase the complexity of processes, particularly in regard to safety. Containment solutions are, therefore, crucial for applications like powder handling during feeding, metering, discharge or even sampling.

Dispense, transfer and contain sampling ingredients with a single-use valve system

Andocksysteme developed a passive-passive split butterfly valve to discharge hazardous substances safely and reliably. The AVAX valve system meets the occupational exposure limits of ≤ 1 µg/m³ (OEB 5 requirements).

The hygienic components comply with the specific requirements of pharmaceutical and biopharmaceutical standards produced in a cleanroom environment. The solutions are also suitable for sterile applications.

The AVAX valve applies the bayonet coupling method to ensure superior containment performance during dispensing and handling.

This containment interface can be optionally be pre-fitted with different bag volumes and executions as complete product transfer solution serving different process challenges.

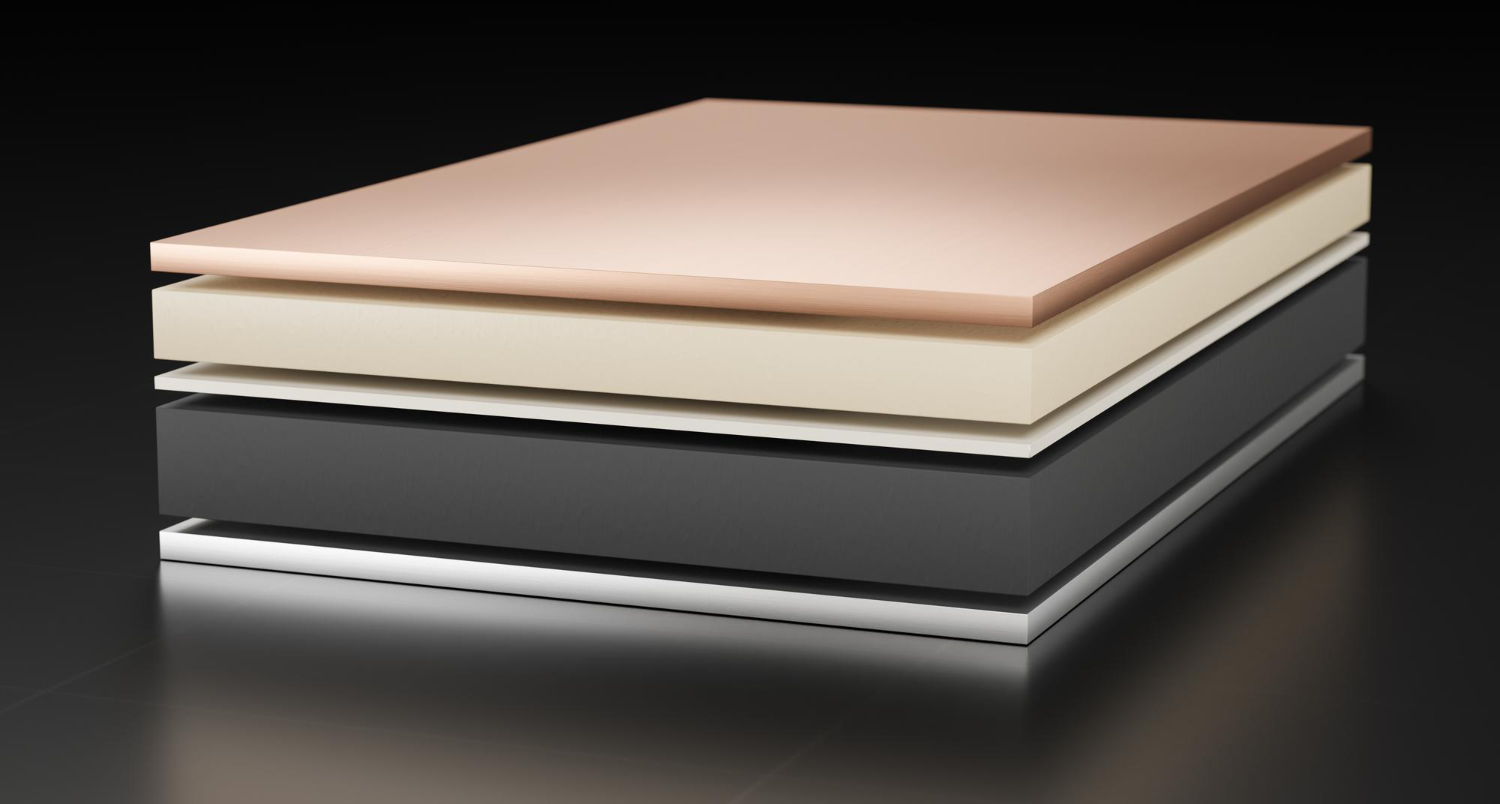

The system is also available in stainless steel and optional with an active flange execution. This range of versions is fully compatible and components fit seamlessly to each other no matter their material.

Benefits

- Intuitive and safe handling

- Integrated Tri-Clamps seal

- Includes a protective cap and multi-tool

- Optionally pre-sterilized (gamma-irradiated)

- Mutual locking motion

- FDA, USP, EP compliant