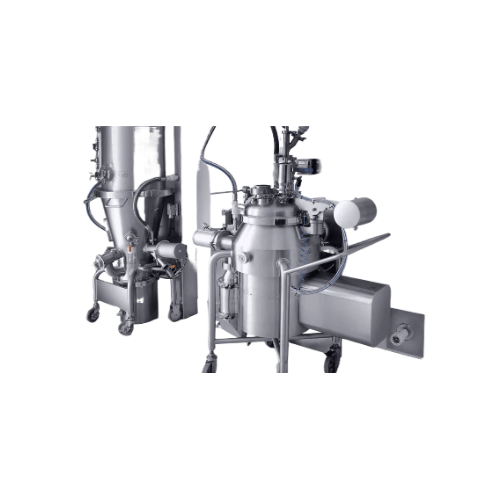

Integrated small-scale granulation and drying system

Ensure precise granule size and moisture control for enhanced tablet formulation in small-scale pharmaceutical production, optimizing R&D outcomes with adaptable batch processing.

Integrates Granulation, Drying, and Conveying Processes

The PharmaConnect® PLUS from GEA is a versatile system designed for precision granulation and drying in the pharmaceutical and biotech industries. It features a modular design, allowing seamless integration of high shear granulators with fluid bed processors for batch sizes up to 60 kg. Common applications include producing paracetamol tablets, iron supplements, and omega-3 capsules. The system’s automation, supported by GEA’s containment valve technologies, ensures safe material handling and compliance with regulatory standards. Equipped with GEA’s lean phase conveying technology, it facilitates efficient, contained transfer and minimal cleaning downtime. Ideal for R&D and small-scale production, it facilitates 1:10 scale-up procedures, ensuring efficient process development and optimization.

Benefits

- Enhances safety with OEB 4 containment for potent compounds.

- Facilitates process scalability with batch operations from 5 to 60 kg.

- Reduces product loss and contamination risk with integrated lean phase conveying.

- Complies with regulatory requirements for pharmaceutical production.

- Minimizes cleaning time with modular, easily accessible design.

- Applications

- Supplements, Vitamins, Fine chemicals, Pharmaceutical tablets, Nutraceuticals, Pharmaceutical powder

- End products

- Ibuprofen tablets, Herbal extract powders, Probiotic capsules, Antihistamine tablets, Antidepressant tablets, Vitamin c supplements, Calcium tablets, Omega-3 capsules, Iron supplements, Paracetamol tablets

- Steps before

- Raw Material Loading, High Shear Granulation

- Steps after

- Drying, Product Handling, Finished Product IBC Transfer

- Input ingredients

- raw materials, potent actives

- Output ingredients

- granulated product, dry granules, finished product IBC

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Batch size

- 5–60 kg

- Containment level

- OEB 4

- Automation

- Integrated control unit

- Drying integration

- Fluid bed processor

- Granulation type

- High shear

- Scale-up capability

- 1

- Discharge method

- Integrated wet mill

- Product transfer

- Lean phase conveying

- Control integration

- With FlexStream systems

- Valves

- BUCK® containment, Hicoflex®

- Working Mechanism

- Integrated high shear granulation

- Integrated Steps

- Granulation and drying

- CIP/SIP

- CIP for cleaning

- Batch Size Flexibility

- 5 kg to 60 kg

- Containment Level

- OEB 4

- Scaling

- 1

- Automation Level

- PLC controlled

- Material Transfer Method

- Lean phase conveying

- Batch vs. Continuous Operation

- Batch operation

- Biological compatibility

- Suitable for pharmaceutical use

- Cleanability

- Easy to clean with compliant cleaning standards

- Corrosive resistance (e.g. acids)

- Utilizes stainless steel or corrosion-resistant materials

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- OEB Containment Levels

- OEB 4

- Batch size

- 5–60 kg

- Discharge method

- Integrated wet mill

- Modular concept

- Single control unit with process modules

- Control panel type

- Single control unit

- Integration possibilities

- Integrated with GEA’s fluidized bed processors (FlexStream 500 and 1000)

- Modular design

- Multiple process modules

- Capacity range

- 5 kg to 60 kg

- Containment options

- BUCK® MC valve and Hicoflex® system