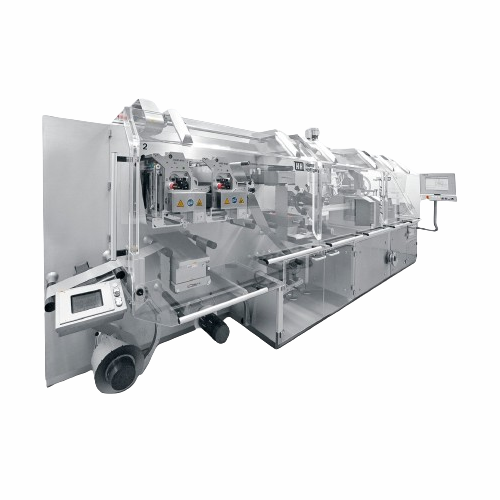

Pharmaceutical powder bag filling system

Ensure precision in pharmaceutical formulations with a system that fills high-speed packets, ensuring secure sealing and thorough inspection for quality maintenance.

Fills, Seals, and Inspects Pharmaceutical Bags

The PPH from Harro Höfliger is a highly specialized vertical filling and sealing machine designed for pharmaceutical applications. It efficiently produces four-edge seal bags, filling them with powders and bulk goods while ensuring compliance with GMP standards. The machine features a round motion unit for sensory inspection and precision dosing, supported by a 100% weight inspection system. Capable of producing up to 300 bags per minute, the PPH integrates seamlessly into your production line with its fully automatic operation and stack transport to downstream cartoning machines. Its PLC-controlled system allows for parameterized batch releases, ensuring fast and reliable product delivery. Engineered with separate quality monitoring and a completely protected production area, the PPH excels in maintaining product integrity. It features options for micro-dosing and inline printing, utilizing various sealing technologies and powerful camera inspection systems to guarantee sterility and annotate packages effectively with thermotransfer, inkjet, or laser systems, making it an invaluable asset for pharmaceutical manufacturers and healthcare product companies.

Benefits

- Enhances production efficiency with high-speed output of up to 300 bags per minute.

- Ensures product integrity with 100% weight inspection and full sensory inspection.

- Facilitates regulatory compliance with GMP design and protected production areas.

- Increases operational flexibility with the ability to handle multiple bag formats and dosing ranges.

- Minimizes packaging errors with advanced camera systems for quality control and inline printing capabilities.

- Applications

- Pharmaceutical powder, Pharmaceutical media, Bulk goods, Pharmaceutical products

- End products

- Pharmaceutical bulk drug sachets, Nutritional supplement bags, Over-the-counter medicine granule packets, Protein powder sachets, Antibiotic powder packets

- Steps before

- Purification, Drying, Grinding, Emulsification

- Steps after

- Cartoning, Secondary Packaging, Sterilization

- Input ingredients

- packaging film, powder, bulk goods, pharmaceutical media

- Output ingredients

- four-edge sealing bags, hermetically sealed bag packages, folding boxes

- Market info

- Harro Hoefliger is known for its expertise in manufacturing custom, engineered-to-order packaging and production equipment, particularly for the pharmaceutical, healthcare, consumer goods, and chemical industries, with a reputation for precision, innovation, and quality engineering solutions.

- Output

- 80/160/300 bags/min

- Bag format area

- L

- Dosing range

- 1 mg – 500 mg/bags

- Weight inspection accuracy

- 100%

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Automation level

- PLC / SCADA

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat Sensitivity

- Yes/No

- Foaming Tendency

- Low/Medium/High

- Viscosity

- 1 cp - 1000 cp

- Container Size and Shape

- Various

- Discharge method

- Stacking and cartoning

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- Compatible with existing production lines

- Batch release

- Parameterized

- Micro-dosing systems integration

- Powder / Bulk goods / Liquid

- Sealing technology

- Platen / Roller / Ultrasonic