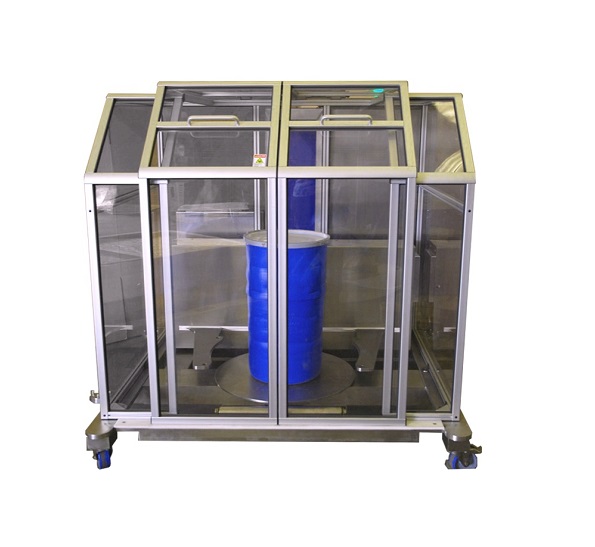

Drum conditioner

Many pharmaceutical production processes involve the use of products that have naturally hardened within their transport container and need to be conditioned before they are able to be used as inputs to the production process. Traditionally manual methods of percussion, using mallets for example, have been used, but these are unsatisfactory from both a safety and efficiency point of view. A dedicated system for the manipulation of a wide range of container types provides a professional, safe and automated conditioning process that improves productivity.

Automated drum conditioning systems for a wide range of pharmaceutical containers

The PalPharMassage from Palamatic is a custom-designed range of drum and container conditioning solutions designed to meet the needs of the pharmaceutical industry.The range includes conditioners that can handle various containers – fibre and plastic drums, kegs, sacks, and other flexible containers.

Featuring full PLC control with an intuitive touchscreen HMI, the PalPharMassage is simple to operate with infinitely variable controls for distance into container, torque, speed and time. Recipe programming further simplifies operation by allowing for “one touch” automated operation.

Giving you complete flexibility to fit your exact requirements, the PalPharMassage unit can be specified in fixed or mobile formats and is robustly constructed for longevity and reliability. Built from 304 to 316L stainless, the whole range is fully cGMP compliant and can be specified to meet ATEX requirements.

Available in a MAXI format that suits the widest range of container styles, the PalPharMassage is also available in an economical pneumatic-only MINI format for use with smaller containers.

Benefits

- Full cGMP compliance with ATEX available as an option

- Rugged construction to withstand high usage levels

- MINI and MAXI format options to suit your exact requirements and budget

- Mobile option available for maximum flexibility

- Range of load/unload accessories includes roller conveyor, dolly and vacuum lifter systems