Automatic centrifuge for lithium carbonate

The battery industry requires high purity components. To obtain more than 99.5% lithium carbonate production-technologies must perform several complex steps. The lithium carbonate separation step uses a vertical peeler centrifuge to separate solid particles from liquid, where the scrapped solids are discharged through the bottom of the centrifuge vessel. It is suited for high throughput and flexibility in the filling, intensive washing, and solid discharge steps.

High rotating speed centrifuge filtering to separate mixtures

The RINA Serie 300 Vertical Automatic by Riera Nadeu are high rotating speed vertical centrifuges with automatic discharge dedicated to the solid-liquid separation of slurries. The RINA Serie 300 has two versions, particularly the 300 F filtering (“F” version) and the 300 D decanting basket (“D” version). The RINA 300F is a filtering version for separating mixtures such as lithium carbonate, oxalic acid, salicylic acid, and others. It is used when the solid suspension forms a permeable cake inside the drilled basket. The bottom of the centrifuge contains the solids automatically discharged during the scraping phase. The filtering version’s retention capacity can hold up to 55 to 1300 dm3 and varies from 500 up to 1800 mm basket diameter.

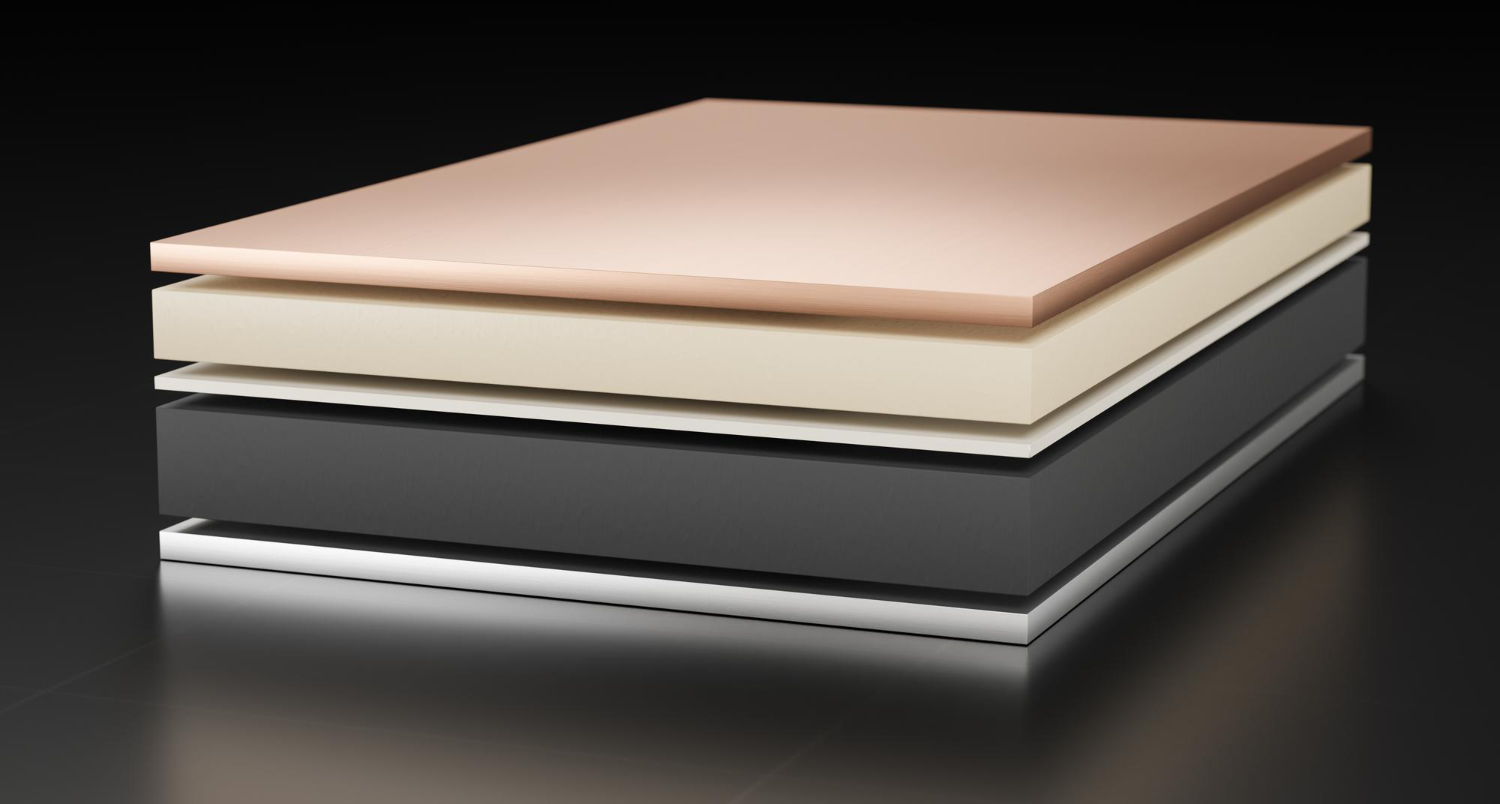

The RINA 300F is especially recommended for products requiring variable residence time when spinning and intensive washing. It features multiple configurations and working recipes, including blanketing, spinning, washing(s), automatic discharge, CIP, etc. As a result, the Rina 300F is easy to use, versatile, and low maintenance while also adaptable to work in an explosive hazardous area. It can also be manufactured in various materials, from basic steel to high-grade alloy.

Benefits

- Modular concept and customizable

- Oil-free double effect scrapper

- High G-factor that ensures purity