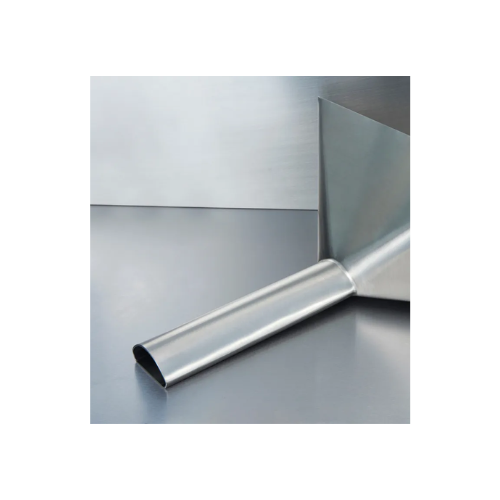

Powder dispensing funnel

Enhance powder handling accuracy while minimizing product loss with a precision-engineered dispensing funnel designed to streamline your containment and transfer processes.

Facilitates Precise Powder Dispensing and Containment

The Dispensing Funnel by ChargePoint Technology is a key component in powder handling systems, designed to provide precise and clean dispensing. It’s uniquely crafted to direct powders through a ChargePoint valve, minimizing product loss and dust exposure. Ideal for pharmaceutical, biotech, and chemical industries, it supports the production of items such as paracetamol tablets and lithium-ion battery electrodes. Typically used in conjunction with dispensing isolators, this funnel ensures powders bypass direct valve contact, maintaining a high level of containment. Constructed from 316L stainless steel, it offers durability and corrosion resistance. The Dispensing Funnel is compatible with valve sizes from DN50mm (2″) to DN150mm (6″), facilitating a versatile integration into various operations. Its design allows for easy cleaning and reduced maintenance, ensuring reliable, long-term performance in demanding manufacturing environments.

Benefits

- Enhances operational safety by minimizing dust exposure during powder transfers.

- Reduces product waste through precise powder containment and direction.

- Facilitates easy integration into existing containment systems with compatible valve sizes.

- Supports compliance with industry containment standards to ensure safe processing environments.

- Offers durable performance with corrosion-resistant 316L stainless steel construction.

- Applications

- Supplements, Vitamins, Batteries, Fine chemicals, Nutraceuticals, Pharmaceutical powder, Biopharmaceuticals, Enzymes

- End products

- Coenzyme q10 capsules, Lithium-ion battery electrodes, Ascorbic acid tablets, Enzyme powder blends, Probiotic capsules, Biopharmaceutical active ingredients, Paracetamol tablets, Amino acid supplements

- Steps before

- Powder Mixing, Drying

- Steps after

- Powder Containment, Dust Minimization

- Input ingredients

- powder

- Output ingredients

- powder, dust

- Market info

- Chargepoint Technology is known for its expertise in designing and manufacturing high containment and sterile transfer solutions for pharmaceutical and biopharmaceutical industries, particularly in powder containment and aseptic transfer systems.

- Valve size compatibility

- DN50mm (2”) to DN150mm (6”)

- Material of construction

- 316L Stainless Steel

- Dispensing accuracy

- High

- Containment performance

- Maximized

- Dust exposure minimization

- Yes

- Simplicity of design

- Basic/Advanced systems

- Cleansing method

- Manual/Valved transfer

- Integrated function

- Powder directing, loss reduction

- Open valve use

- Valve disc side positioning

- Cleaning requirement after operation

- Minimised dust

- Handling mechanism

- Funnel, Valve system

- Adaptability to valve designs

- Basic, Advanced

- Cleanability

- 316L Stainless Steel

- Corrosive resistance (e.g. acids)

- 316L Stainless Steel

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Dispensing application

- Powder dispensing operations

- Dispensing accuracy

- High

- Size (valve size compatibility)

- DN50mm (2”) to DN150mm (6”)

- Materials of construction

- 316L Stainless Steel

- Discharge method

- Clean dispensing through ChargePoint® valve

- Design

- Funnel with side legs

- Footprint

- Within a dispensing isolator

- Dispensing method

- Clean dispensing through ChargePoint® valve

- Containment performance

- Maximized containment and dispensing accuracy