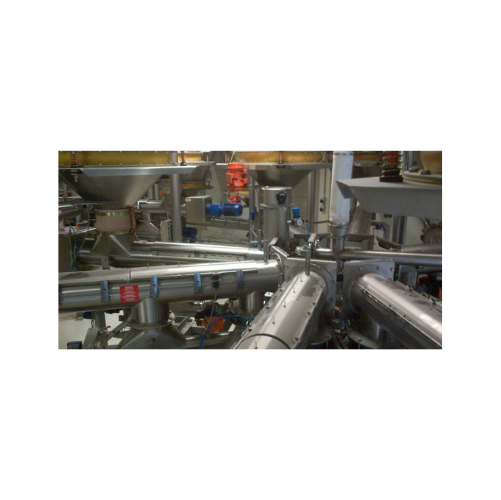

Stainless steel tubular screw conveyor for bulk solids handling

Ensure precise material handling with stainless steel tubular screw conveyors, designed to prevent contamination and maintain high hygiene standards across your production line. Ideal for maintaining product integrity in sensitive processing environments.

Conveys and Feeds Powdery and Granular Materials

The TX Stainless Steel Tubular Screw Conveyor from WAMGROUP is expertly engineered to handle your material processing needs with precision and reliability. This modular screw conveyor system is crafted from durable 304L or 316L stainless steel, ensuring corrosion resistance and minimal material residue due to its perfectly smooth surface finish. Designed to seamlessly convey and feed powdery and granular materials, the TX Screw Conveyor is a compact solution optimized for industries such as pharmaceuticals, food processing, animal feed, and plastics.

Operating continuously at high speeds, this machine features a robust helicoid screw flighting, welded onto a center pipe, effectively transporting materials like pharmaceutical tablets and plastic pellets. Its flexibility extends to customization options, including variable pitch screw designs and different shaft seals, to accommodate diverse processing requirements.

Equipped with WAM drive units, these conveyors ensure balanced operation by mounting the drive unit directly on the screw pipe, eliminating the need for couplings or chain transmissions. With AtEX Zone 22 certification, the TX Screw Conveyor meets industry safety standards, while options like drop-bottom tubes and inspection hatches facilitate maintenance.

Expertly integrating into pre-processing and processing departments, this TX Conveyor is well-suited to your energy-efficient operations, reducing energy consumption through its specially configured motor control.

Benefits

- Minimizes contamination risk with stainless steel construction and smooth surface finish.

- Increases operational efficiency with continuous, high-speed processing capabilities.

- Enhances versatility with customizable configurations for varied industry applications.

- Reduces maintenance time with easy access options like drop-bottom tubes and inspection hatches.

- Ensures compliance with safety standards with ATEX Zone 22 certification.

- Applications

- Chemicals, Animal feed, Food packaging, Food processing, Environmental technology, Flour milling, Plastics, Pharmaceutical industry

- End products

- Detergents, Powdered soup bases, Pharmaceutical tablets, Wheat flour, Wastewater sludge cakes, Bakery mixes, Animal feed pellets, Plastic pellets

- Steps before

- Purification, Grinding, Blending, Mixing

- Steps after

- Sterilization, Packing, Coating, Bagging

- Input ingredients

- powdery materials, granular materials, flour, animal feed, food products, plastics, chemicals, pharmaceuticals

- Output ingredients

- conveyed powdery materials, conveyed granular materials, processed flour, processed animal feed, packaged food products, processed plastics, processed chemicals, pharmaceutical products

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Construction Material

- 304L or 316L Stainless Steel

- Corrosion Resistance

- High

- Smooth Surface Finish

- Yes

- Gear Motor

- Integrated

- Design

- Modular Length

- Shaft Seal

- Adjustable

- Various options (stuffing box,air or gas-purged)

- Helicoid Screw Flighting

- With square or variable pitch

- Intermediate Hanger Bearings

- Range available

- Self-lubricating on request

- Drive Unit

- WAM drive unit with direct mount, integrated end bearing

- Corrosion resistance

- High (Stainless Steel 304L or 316L)

- Batch vs. continuous operation

- Continuous

- Automation level

- Integrated motor and control

- Conveying method

- Helicoid screw flighting

- Cleaning method

- Manual / Easy Clean Features

- ATEX certification

- Zone 22

- Maintenance-friendly design

- Yes

- Material residue minimization

- Perfectly smooth surfaces

- Corrosive resistance

- Perfect resistance to corrosion

- Cleanability

- No material residue

- Biological compatibility

- Suitable for food and pharmaceutical applications

- Material type

- Powdery / Granular

- ATEX certification

- Zone 22

- Tubular trough design

- Stainless steel

- Helicoid screw flighting

- Welded on center pipe

- Discharge method

- End outlet spout

- Footprint

- Modular and customizable

- Screw sections connection

- Splined or bolted shaft couplings

- End bearing assemblies

- Externally adjustable shaft seal

- Surface finish grade

- Application-specific

- Gear motor

- Application-appropriate

- Length option

- Light or medium heavy-duty design

- End bearing assemblies

- Externally adjustable shaft seal

- Intermediate hanger bearings

- Self-lubricating on request

- Screw sections

- Connected by splined or bolted shaft couplings

- Drive units

- Integrated end bearing assembly

- Shaft seals

- Stuffing box, air or gas-purged, others

- Power transmissions

- Coupling, chain, belt-type

- Different screw designs

- Light or medium heavy-duty design

- Inspection hatches

- Additional inspection and overflow hatches

- Screw flighting pitch

- Double pitch flight in outlet zone