Contamination free filling system

Liners for powder handling across industries must prevent contamination of materials to comply with GMP. But individual bag or drum filling systems cannot guarantee complete sterilization standards during bag removal and exchange. Moreover, they may lead to concerns about operator safety.

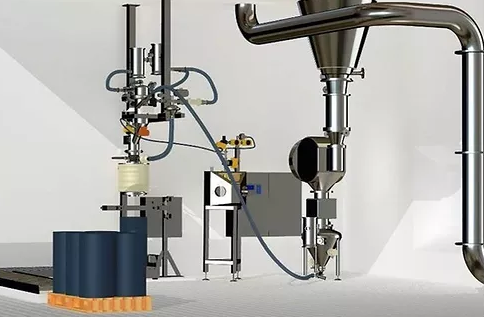

Liner system for bag and drum filling of powders with high containment level

CLS Continuous Liner System from Dec Group offers complete solutions for packaging different powder materials into bags and drums. Depending on the liner and cartridge dimensions, the system carries folded bags up to 80 meters. Its filling head can be installed directly at the discharge outlet of the machine or on a support frame with load cells for weighing. Moreover, the liner is attached to the support clips for safe bag detachment.

The liner is produced in a clean ISO 5 environment with the option of γ-irradiated cartridges for sterile use. It can be delivered pre-folded in various sizes and supplied in a PE bag.

Additional features include rollers for heavy loads, a breather vent filter, and a precise dispensing mechanism through the inertisation of liner and dosing device. The system integrates into other process equipment like mixers, dryers, or powder transfer systems.

Benefits

- Manufactured in ISO 5 environment and may be γ-irradiated for sterile use

- Liners Up to 80m in length

- Can attain a high level of containment, <1µg/m3