Cooling conveyor belt for extrudates and granules

Efficiently cool and convey extrudates and granules with precise temperature regulation, ensuring product integrity and consistent quality in demanding production environments.

Cools and Conveys Extrudates Efficiently

The Cooling Conveyor Belt from Three-Tec GmbH is an expertly engineered solution for extrusion and processing industries. Designed to afford precise, gentle cooling and conveying of extrudates and granules, it integrates into continuous operations to ensure quality control and efficiency. Actively cooled elements maintain optimal temperatures, combined with air connections for enhanced air cooling. The belt speed is adjustable from 0 to 20 m/min, controlled via an integrated frequency converter or through the Three-Tec extruder’s control system, facilitating easy integration into existing lines.

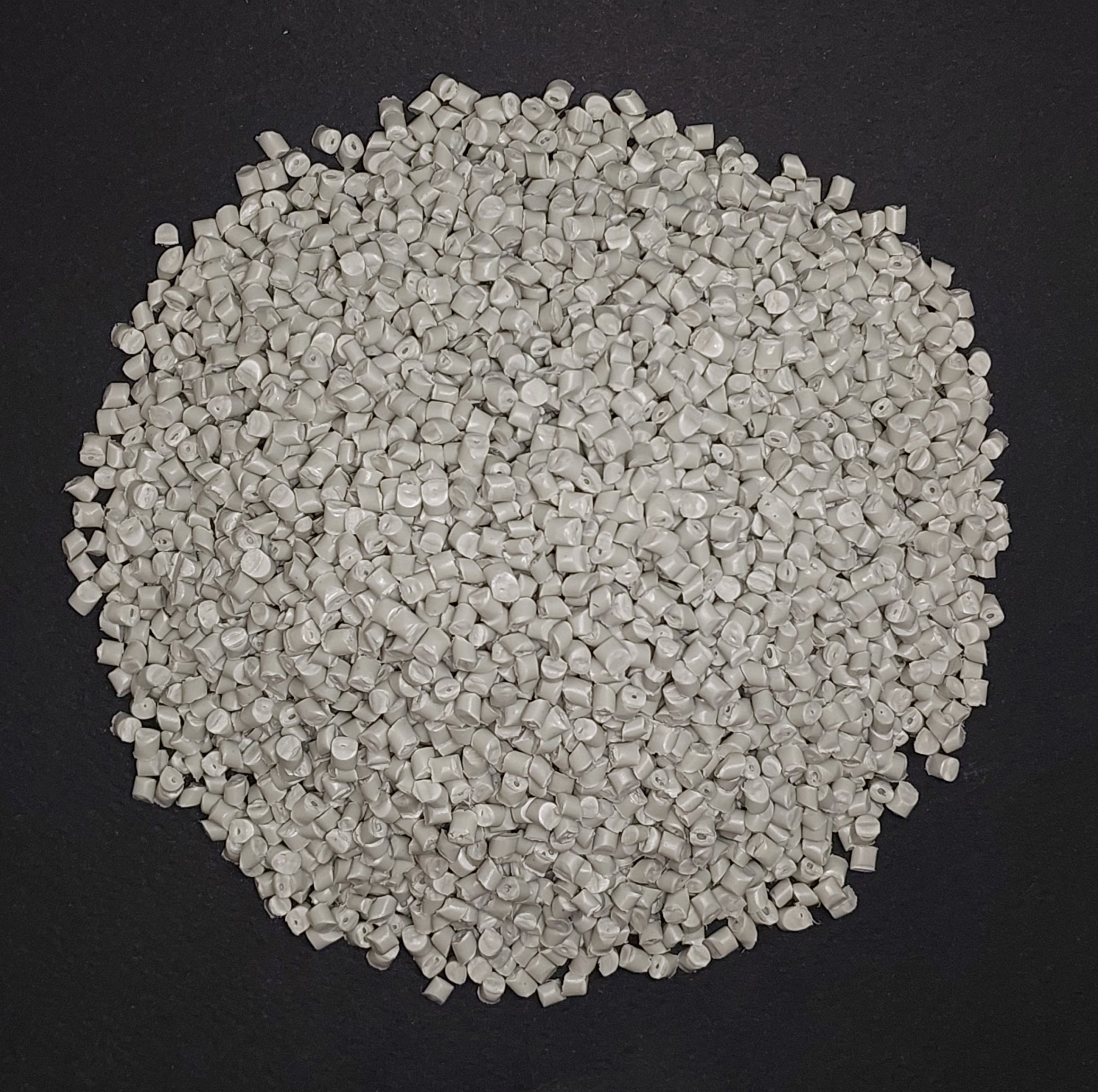

Ideal for applications across pharmaceuticals, plastics, food, and chemical industries, this cooling conveyor is essential for producing end products like polyethylene pellets, pharmaceutical tablets, and biodegradable plastic granules. With a cooling capacity of 1.2 kW and a flow rate of 35 l/min, it supports product temperatures up to 300°C, ensuring versatility. Constructed from materials like silicone or PTFE, it meets diverse processing needs and offers adjustable height and angle for flexibility. This system operates efficiently within a voltage range of 100 to 240 VAC and features a touch screen interface for seamless control.

Benefits

- Enhances product quality with precise temperature control during cooling.

- Increases operational efficiency with adjustable conveyor speeds up to 20 m/min.

- Reduces downtime through easy integration with existing extrusion systems.

- Supports high-temperature operations, accommodating products up to 300°C.

- Adapts to diverse production needs with adjustable height and angle settings.

- Applications

- Extrudates, Granules, Chemical compounds, Plastics, Food products, Pharmaceuticals

- End products

- Polyethylene pellets, Chemical powders, Granola clusters, Pharmaceutical tablets, Nylon extrudates, Polypropylene granules, Snack pellets, Effervescent tablets, Biodegradable plastic granules, Vitamin granules

- Steps before

- Extrusion, Granulation

- Steps after

- Cooling, Conveying

- Input ingredients

- extrudates, granules

- Output ingredients

- cooled extrudates, cooled granules

- Market info

- Three-Tec is known for its expertise in manufacturing precision dosing and feeding systems for industrial applications, with a strong reputation for customizable engineered-to-order equipment and innovative solutions tailored to specific customer needs.

- Speed

- 0 to 20 m/min

- Capacity

- 1.2 kW

- Length

- 2, 000 mm

- Width

- 300 mm

- Height

- 600 to 900 mm (adjustable)

- Angle

- 0 to 20°

- Temperature resistance (continuous)

- -30 to 150 °C

- Temperature resistance (short)

- -50 to 180 °C

- Max. product temperature

- 300 °C

- Flow rate cooling

- 35 l/min

- Voltage

- 100 to 240 VAC

- Frequency

- 50 / 60 Hz

- Motor power

- 0.46 kW

- Control type

- Touch Screen

- Material of conveyor belt

- Silicone or PTFE

- Air cooling integration

- Lid air connections

- Belt speed adjustment

- 0 to 20 m/min

- Control system

- Integrated frequency converter / Optional extruder control

- Temperature resistance in continuous operation

- -30 to 150 °C

- Temperature resistance in short operation

- -50 to 180 °C

- Max product temperature

- 300 °C

- Cooling capacity

- 1.2 kW

- Flow rate cooling

- 35 l/min

- Variable angle

- 0 to 20°

- Height adjustability

- 600 to 900 mm

- Motor power

- 0.46 kW

- Voltage

- 100 to 240 VAC

- Frequency

- 50 / 60 Hz

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 2000 mm length x 300 mm width x 600-900 mm height

- Angle adjustability

- 0 to 20°

- Temperature resistance (continuous operation)

- -30 to 150 °C

- Temperature resistance (short operation)

- -50 to 180 °C

- Max. product temperature

- 300 °C

- Cooling capacity

- 1.2 kW

- Flow rate cooling

- 35 l/min

- Speed

- 1 to 20 m/min

- Voltage

- 100 to 240 VAC

- Frequency

- 50 / 60 Hz

- Motor power

- 0.46 kW

- Control type

- Touch Screen

- Material conveyor belt

- Silicone or PTFE

- Control method

- Integrated frequency converter / Extruder control system

- Belt speed adjustment

- 0-20 m/min

- Height adjustment

- 600 to 900 mm

- Angle adjustment

- 0 to 20°

- Material conveyor belt

- Silicone or PTFE

- Additional cooling

- Air connections in the lid

- Touch Screen

- Control