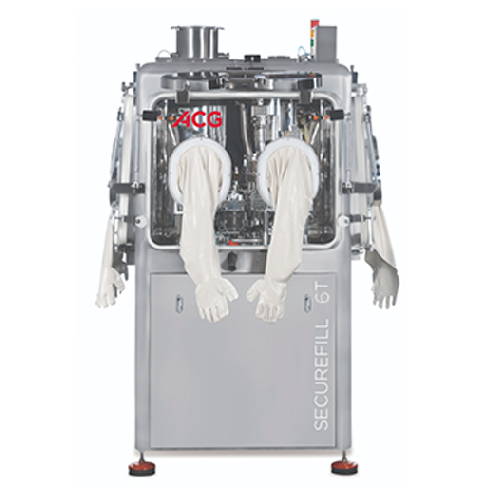

Containment capsule filling system for highly potent drugs

Ensure operator safety while filling capsules with high-potency drugs, including oncological and hormonal formulations, with this robust and precision-engineered containment system.

Ensures Safe Containment and Precise Capsule Filling

The SECUREFILL 6T from ACG is a high-containment capsule filling machine designed specifically for the precise and safe handling of highly potent active pharmaceutical ingredients (HPAPIs). Utilizing a monoblock structure of SS316L, this equipment incorporates HEPA filters, rapid transfer ports, and glove ports, maintaining a negative pressure environment to ensure operator safety. Ideal for biopharmaceuticals and oncological drug production, it efficiently handles the filling of capsules, soft gels, tablets, micro-tablets, and pellets. With a capacity of up to 6,000 capsules per hour, it supports both small batch and continuous production environments. The machine’s wet-in-place system and comprehensive containment features protect against formulation residues, facilitating easy cleaning and reducing contamination risks. Fully integrated for upstream and downstream processes, it complies with OEB level 4 standards and can seamlessly connect with check-weighers, metal detectors, and de-dusters, ensuring quality and safety across the production line.

Benefits

- Ensures operator safety by maintaining containment within the OEL range of 1-10 µg/m³.

- Supports efficient handling of highly potent drugs, reducing risk and compliance concerns.

- Facilitates easy cleaning and minimizes contamination with its wet-in-place system.

- Integrates with existing production lines, enhancing operational efficiency with upstream and downstream compatibility.

- Certified for OEB level 4, ensuring adherence to strict safety and environmental standards.

- Applications

- Pharmaceutical capsules, Soft gels, Pellets, Hormonal drugs, Micro-tablets, Biopharmaceuticals, Highly potent active pharmaceutical ingredients (hpapis), Tablets, Oncological drugs, Antiviral formulations

- End products

- Oseltamivir phosphate capsules, Anastrozole, Acyclovir tablets, Omega-3 soft gels, Erythropoietin, Tamoxifen, Vitamin d pellets, Dexamethasone, Progesterone, Nirmatrelvir, Levothyroxine, Paroxetine micro-tablets, Multi-vitamin capsules, Azithromycin capsules, Ritonavir, Lamivudine, Trastuzumab, Interferon

- Steps before

- Granulation, Active pharmaceutical ingredient preparation, Material dosing, Mixing

- Steps after

- Capsule check-weighing, Metal detection, De-dusting, Packing

- Input ingredients

- pellets, tablets, micro-tablets, capsules, soft gels, highly potent active pharmaceutical ingredients (HPAPIs), oncological formulations, hormonal formulations, biopharmaceutical formulations, antiviral formulations

- Output ingredients

- filled capsules

- Market info

- ACG World is known for manufacturing capsules and capsule filling machines, providing integrated pharmaceutical solutions with a strong reputation for innovation, quality, and comprehensive service offerings in the pharmaceutical manufacturing industry.

- Capsule sizes

- 00 - 5

- Maximum speed

- 6, 000 capsules/hr

- OEL

- 1-10 µg/m³

- Compliance

- OEB up to level 4

- Material of Construction

- SS316L

- Containment level

- High containment

- HEPA filter

- Included

- Wet-in-place system

- Yes

- Integrated systems

- Check-weighers, metal detectors, de-dusters

- Batch vs. continuous operation

- Batch

- Cleaning method

- Wet-in-place system

- CIP/SIP

- Wet-in-place

- Automation level

- PLC-controlled

- Containment capability

- OEB Level 4

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Occupational Exposure Band (OEB)

- Level 4

- Control Panel Type

- Touchscreen

- Compact Footprint

- Yes

- Control panel type

- PLC

- Monoblock structure

- SS316L

- HEPA filters

- Included

- Glove ports

- Included

- Rapid transfer port (RTP)

- Included