Vapour recovery unit for terminals and refineries

Efficiently capture and recover valuable hydrocarbons from gas streams, meeting stringent emission limits while optimizing product yield with this advanced vapour recovery technology.

Recovers and Purifies Hydrocarbon Vapors

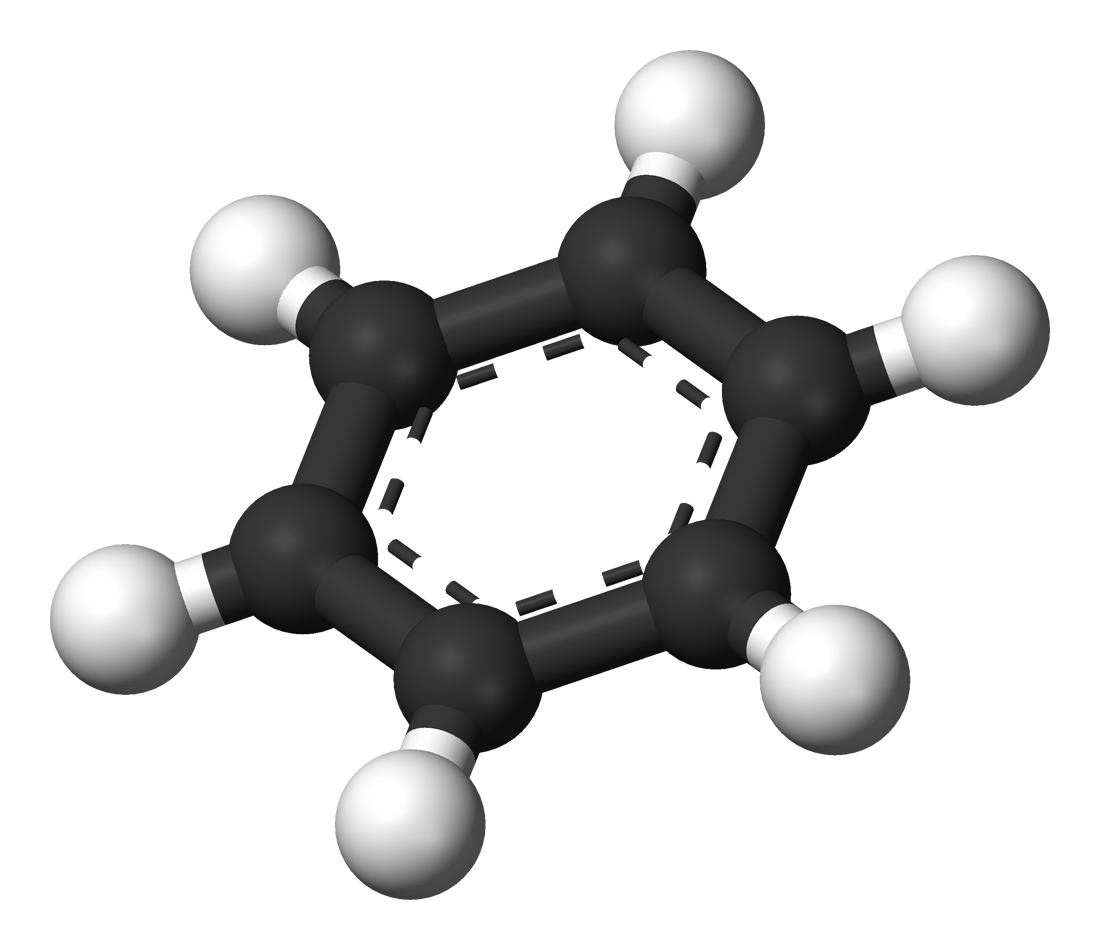

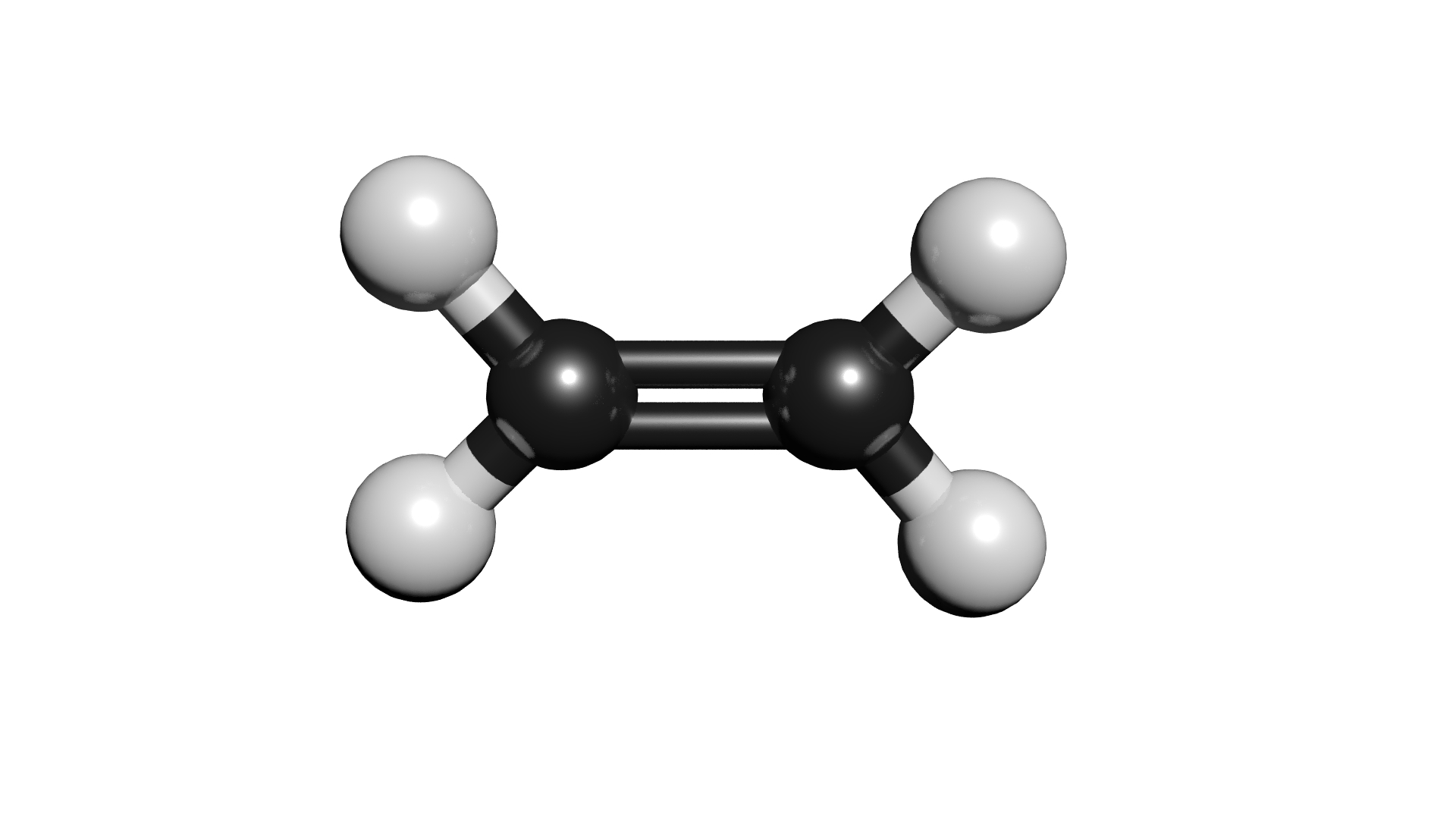

The BORSIG Vapour Recovery Unit (VRU) integrates cutting-edge membrane technology and robust engineering to deliver efficient hydrocarbon recovery in refineries and petrochemical facilities. Featuring a combination of liquid ring compressors, scrubber columns, membrane stages, and vacuum pumps, this unit effectively processes gas streams through absorption, condensation, and membrane separation. The VRU is ideal for terminals handling gasoline, diesel, and jet fuel, as well as chemical processing plants dealing with aromatic compounds like benzene and toluene. Designed for continuous, fully automated operation, the system’s modular, skid-mounted architecture ensures easy integration and scalability to fit specific site requirements. Engineered with high-quality materials, including stainless steel, it promises low maintenance and high reliability. This unit meets customer codes and standards, supporting energy-efficient processes that enhance environmental compliance and product recovery, all while ensuring safe operation with an inherently explosion-proof design.

Benefits

- Enhances emission control compliance by efficiently recovering hydrocarbons from gas streams.

- Reduces operational costs through low-maintenance, high-reliability construction using durable materials.

- Adapts to changing regulations with a flexible, modular design that can handle variable emissions.

- Supports safe operations with a unique explosion-proof design, negating the need for additional safety equipment.

- Integrates seamlessly into existing systems with a customizable, skid-mounted setup.

- Applications

- Hydrocarbons, Terminals, Aromatics, Gas streams, Emission control, Product recovery, Membrane separation, Refineries, Gas separation, Liquids

- End products

- Propylene, Xylene, Toluene, Vaporized hydrocarbons, Carbon dioxide, Benzene, Liquid nitrogen, Industrial solvents, Ethylene, Methane, Gasoline, Hydrogen, Jet fuel, Diesel, Butadiene

- Steps before

- Gas Collection, Hydrocarbon Separation, Scrubbing

- Steps after

- Emission Measurement, Gas Discharge, Product Recovery

- Input ingredients

- gas streams, hydrocarbons

- Output ingredients

- treated gas streams, emission-controlled gases

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Process Type

- Absorption/condensation and membrane separation

- Components

- Liquid ring compressor, scrubber column, membrane stage, vacuum pump

- Operation

- Fully automated

- Design

- Skid-mounted, pre-assembled

- Design Options

- Standardised or tailored

- Efficiency

- High efficiency and recovery

- Capacity Control

- Available

- Maintenance

- Low maintenance due to machinery and material selection

- Materials Used

- Stainless steel

- Explosion Safety

- Inherently safe explosion principle

- Reliability

- High reliability due to high-quality equipment and control system

- Installation

- Self-in taking principle, no blower required

- Working mechanism

- Absorption/Condensation and Membrane Separation

- Integrated steps

- Liquid ring compressor, Scrubber column, Membrane stage, Vacuum pump

- Automation level

- Fully automated

- Batch vs. continuous operation

- Continuous

- Modular design

- Compact, Modular

- Corrosive resistance (e.g. acids)

- Stainless steel

- Compact footprint

- Modular, skid-mounted

- Control panel type

- Automated control systems

- Discharge method

- Self-intaking principle, no blower

- Material selection

- High-quality, stainless steel

- System configuration

- Skid-mounted, pre-assembled

- Flexibility

- Standardized or tailored layouts

- Control panel type

- Automated / Manual

- Skid-mounted design

- Standardized / Tailored

- Integration with existing systems

- Fully integrable

- Customization for site requirements

- Yes

- Capacity control option

- Available

- Material selection

- Stainless steel