Micro-dosing system for pharmaceutical powders in vials

Ensure accurate aseptic dosing of sensitive pharmaceutical powders with high-speed, vacuum/pressure systems designed to minimize contamination and optimize dosage precision.

Precisely Doses Pharmaceutical Powders in Vials

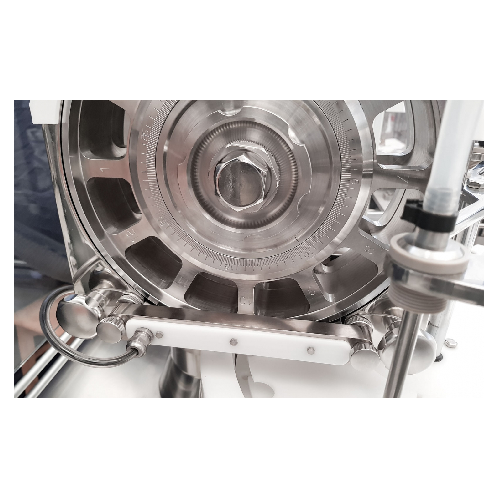

The FV Series equipment from TecnoTrend, part of the Comas Group, is a high-performance micro-dosing solution tailored for pharmaceutical manufacturers requiring precision and aseptic conditions. It features a rotating dosing disk with a vacuum/pressure system, ensuring precise dosing of pharmaceutical powders into vials without spillage. The system accommodates various powders, including lyophilized injectables and vaccine adjuvants, with the capability to handle fine chemicals and nutraceuticals efficiently. Designed for continuous, fully automatic operation, the FV Series supports high throughput with outputs ranging from 6,000 to 18,000 vials per hour, adjustable through time and pressure controls for enhanced accuracy. Integration into existing production lines is streamlined via Siemens PLC controls, with design options available for different vial dimensions and dosage requirements, ensuring compatibility with GMP standards.

Benefits

- Ensures precision and minimizes contamination with vacuum/pressure dosing.

- Increases production flexibility by accommodating dual powder dosing.

- Enhances dosage accuracy with customizable time and pressure settings.

- Boosts productivity with high-speed output, up to 18,000 vials per hour.

- Integrates seamlessly with Siemens PLC for efficient control and operation.

- Applications

- Biopharmaceuticals, Pharmaceutical powder, Nutraceuticals, Fine chemicals

- End products

- Oral rehydration salts, Vaccine adjuvants, Protein powders, Active pharmaceutical ingredients, Vitamin tablets, Enzyme formulations, Probiotic supplements, Lyophilized injectables

- Steps before

- Purification, Drying, Grinding

- Steps after

- Capping, Sterilization, Packing

- Input ingredients

- pharmaceutical powders, low granulometry powders, vials

- Output ingredients

- dosed pharmaceutical powders, filled vials, accurately dosed powders

- Market info

- Speed

- 6, 000 - 18, 000 vials/hr

- Vial Diameter

- 14 mm - 53 mm

- Vial Height

- 35 mm - 140 mm

- Minimum Dose

- 0.2 cc

- Maximum Dose

- 7.5 cc (1.5 g with single dosage)

- Power Consumption

- 7 kW

- Compressed Air Consumption

- 50 Nl/min

- Vacuum Pump Capacity

- 100 m³/h

- Compressed Air Pressure

- 6 bar

- Net Weight

- 1, 100 - 1, 300 kg

- Gross Weight

- 1, 400 - 1, 600 kg

- Automation

- PLC-controlled

- Dosing Type

- Volumetric with Vacuum/Pressure System

- Motion Type

- Intermittent

- Dosing Disc

- Rotating

- Dosage System

- Vacuum/Pressure with Rotating Disk

- Dosing mechanism

- Volumetric vacuum/pressure dosing system

- Dosing disk motion

- Rotating with intermittent motion

- Powder spillage control

- Tighter connection between dosing parts and vials

- Automation level

- Fully automatic

- Adjustability

- Dosage adjustment via time and pressure

- Multiple dosing capability

- Unlimited number of dosages into the same vial

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Dosing group configuration

- Single or dual dosing groups

- Adjustable dosage

- Time and pressure adjustments

- Vacuum/Pressure System

- Volumetric with rotating disk

- Control system

- SIEMENS PLC

- Vial size compatibility

- Diam. 14 mm – 53 mm, Height 35 mm – 140 mm