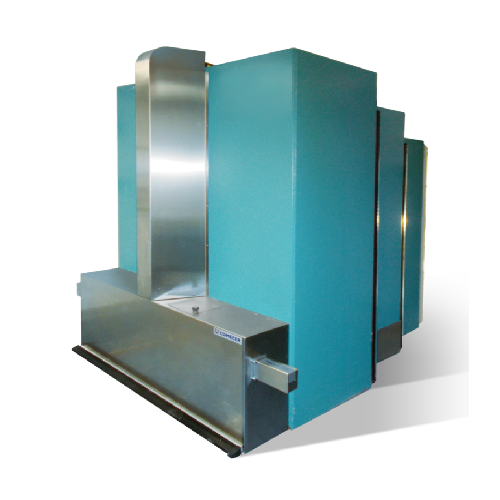

Shielded door for cyclotron bunker

Ensure optimal radiation protection and seamless operation within cyclotron bunkers with this advanced shielded door, precisely engineered to maintain strict safety standards while facilitating efficient workflow in radiopharmaceutical environments.

Provides Radiation Shielding and Controlled Access

The PMC Shielded Sliding Door for Cyclotron Bunkers, developed by COMECER, offers a robust solution for radiation protection and facility safety in radiopharma environments. This door features a steel formwork filled with concrete or barytic concrete, minimizing radiation exposure in cyclotron operations. Precision sliding on steel rails, it utilizes an electric gear motor controlled by an inverter, enabling smooth, automated operation with precise acceleration and deceleration.

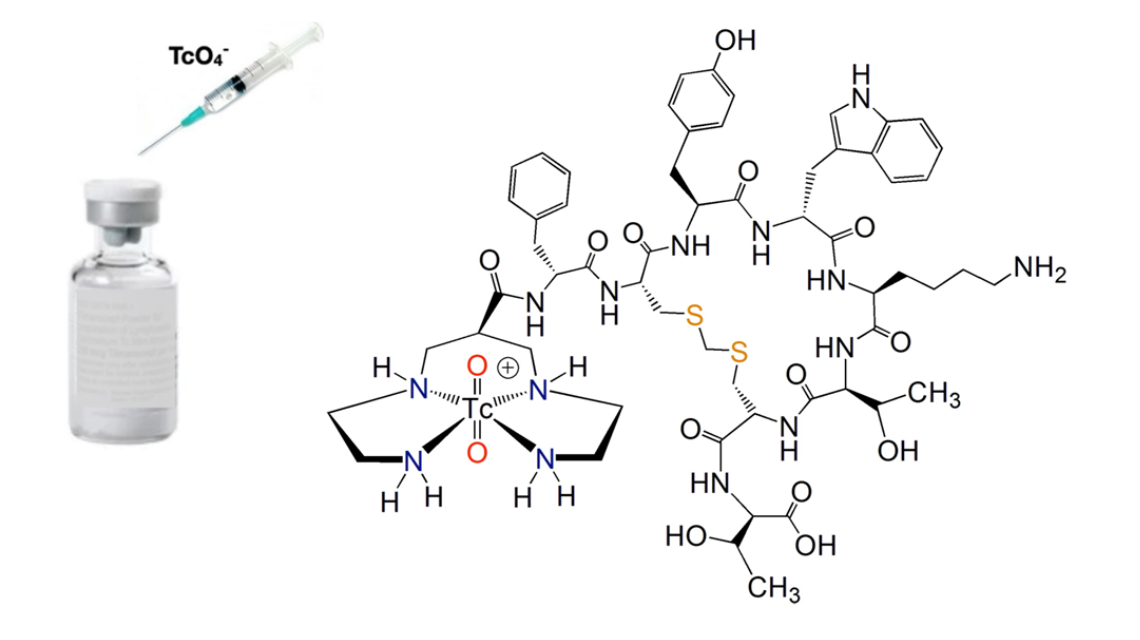

Specially designed for cyclotron bunkers, it effectively supports the production of isotopes such as Fluorodeoxyglucose (FDG) tracers, Carbon-11, Gallium-68, and Technetium-99m radiopharmaceuticals. Accommodating continuous and automated operations, the door ensures seamless integration into production lines, enhancing operational safety with overlapping shieldings and a double-tooth system that guarantees secure sealing. A full silicone ring ensures high-efficiency sealing, maintaining controlled environments.

Engineered for demanding nuclear medicine and radiopharmaceutical industries, this shielded door allows for customized configurations and meets rigorous safety standards, making it an indispensable component in maintaining both safety and efficiency in controlled production settings.

Benefits

- Enhances safety by providing robust radiation shielding and controlled access.

- Ensures environmental control with high-efficiency sealing to maintain laboratory conditions.

- Reduces operational disruptions with smooth, inverter-controlled motion.

- Supports continuous production cycles, optimizing uptime and output.

- Customizable design adapts to specific operational and space requirements.

- Applications

- Cyclotron bunkers, Nuclear medicine, Radiopharmaceuticals

- End products

- Fluorodeoxyglucose (fdg) tracers, Carbon-11 labeled compounds, Iodine-123 radiopharmaceuticals, Technetium-99m radiopharmaceuticals, Gallium-68 radiopharmaceuticals

- Steps before

- Construction of cyclotron bunker, Installation of steel frame, Installation of electric gear motor, Setup of sliding rail system

- Steps after

- Radiation shielding assessment, Safety inspection, Routine maintenance, Operational testing

- Input ingredients

- steel, concrete, barytic concrete, electric gear motor, inverter, silicon ring

- Output ingredients

- shielded cyclotron bunker, overlapping shieldings, sliding door

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Material

- Steel formwork

- Filling Material

- Concrete or barytic concrete casting

- Movement Mechanism

- Wheel system with electric gear motor

- Control System

- Inverter

- Automation

- Mild and linear operation with acceleration and deceleration ramps

- Sealing

- Silicon ring for higher sealing

- Overlap Design

- Double-tooth for overlapping over the wall

- Sliding Mechanism

- Steel rails

- Safety Feature

- Safety photocell

- Door operation

- Electric gear motor with inverter control

- Movement control

- Linear operation with acceleration and deceleration ramps

- Sealing method

- Silicon ring for higher sealing

- Shielding overlap

- Double-tooth for wall overlap

- Safety feature

- Safety photocell

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Door Material

- Steel formwork

- Filling Material

- Concrete or barytic concrete

- Movement Method

- Wheel system

- Control Type

- Electric gear motor with inverter

- Sealing Type

- Silicon ring for higher sealing

- Frame Type

- Steel frame

- Perimeter Seal

- Complete perimeter silicon ring

- Sliding Mechanism

- Steel rails

- Safety Feature

- Safety photocell

- Control panel type

- Electric gear motor controlled by inverter

- Door movement

- Wheel system

- Sealing mechanism

- Silicon ring with higher sealing

- Double-tooth formwork

- Ensures overlapping and perfect coupling

- Integration

- Inverter for controlled operation