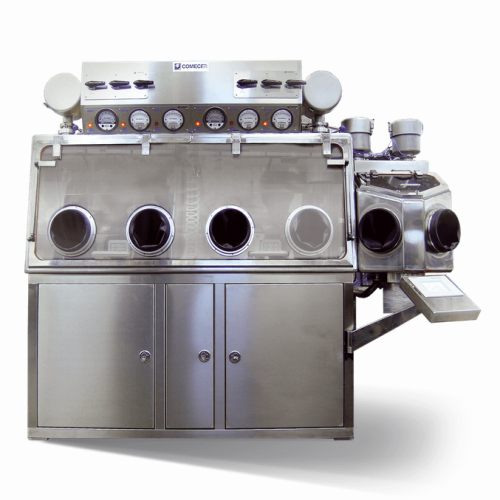

Isolator for cytotoxic drug handling

Ensure safety and compliance in handling cytotoxic drugs and radiopharmaceuticals with this isolator, designed to prevent contamination during processing and decontamination steps, offering an essential solution for high-stakes environments in pharmaceutical and biotech sectors.

Handles and Isolates Cytotoxic Substances Safely

The Isolator for Cytotoxic Manipulation from Comecer provides a secure environment for the preparation and handling of cytotoxic drugs, chemotherapy medications, and advanced therapy medicinal products. This compact unit is ideal for research and development laboratories where containment and operator protection are crucial. Featuring a glovebox design, it uses negative pressure and HEPA H14 filtration to maintain Class A or ISO 5 cleanroom conditions, ensuring the integrity of sensitive pharmaceutical compounds and radiopharmaceuticals like Doxorubicin and Lutetium-177. Fully PLC controlled, it integrates seamlessly into R&D operations, supporting automated handling processes with options for bag-in/bag-out exchanges and VPHP connections for decontamination. Compliant with EC-GMP standards, this isolator is engineered for both liquid and solid product types, offering a customizable solution to meet your specific requirements.

Benefits

- Enhances operator safety through containment of hazardous cytotoxic substances.

- Maintains product integrity with Class A cleanroom conditions, reducing contamination risk.

- Streamlines workflow with integrated PLC-controlled automation.

- Facilitates regulatory compliance with EC-GMP standards.

- Allows flexible operations with customizable and compact design suitable for various R&D labs.

- Applications

- Nuclear medicine substances, Cytotoxic drugs, Cell therapy products, Gene therapy products, Radiopharmaceuticals, Pharmaceutical compounds, Chemotherapy medications, Compounded medications

- End products

- Iodine-123 capsules, Car-t cell therapy products, Autologous cell therapy preparations, Doxorubicin, Cyclophosphamide, Lutetium-177 radiopharmaceuticals, Fluorouracil, Cisplatin, Technetium-99m generators, Methotrexate

- Steps before

- Preparation, Handling, Material transfer

- Steps after

- Decontamination, Waste disposal, Quality control

- Input ingredients

- cytotoxic materials, static products, reactants for cytotoxic manipulation

- Output ingredients

- processed cytotoxic products, handled static products

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Glovebox Environment

- Cleanroom

- Air Filtration

- HEPA H14 filters

- Automation

- Fully PLC controlled

- Compliance

- EC-GMP

- Cleanroom Classification

- ISO 14644-1

- Cleanroom Classification

- FED STD 209E

- Pressure

- Negative pressure relative to the laboratory environment

- Unit Size

- Compact for R, D laboratories

- Bag-in/Bag-out System

- Yes

- VPHP Connection

- Yes

- Automation level

- PLC-controlled

- Pressure conditions

- Negative pressure

- Filtration type

- HEPA H14 filters

- Cleanroom classification

- EC-GMP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Isolator Purpose

- Cytotoxic manipulation

- EC-GMP

- Class A

- ISO 14644-1

- Class ISO 5

- FED STD 209E

- Class 100

- Compact footprint

- Yes

- Bag-in/Bag-out

- Yes