Contained powder sampling system

Ensure contamination-free sampling of active powders with fully contained system integration, minimizing exposure and maintaining process integrity at every stage of pharmaceutical manufacturing.

Ensures Contamination-Free Sampling and Transfer

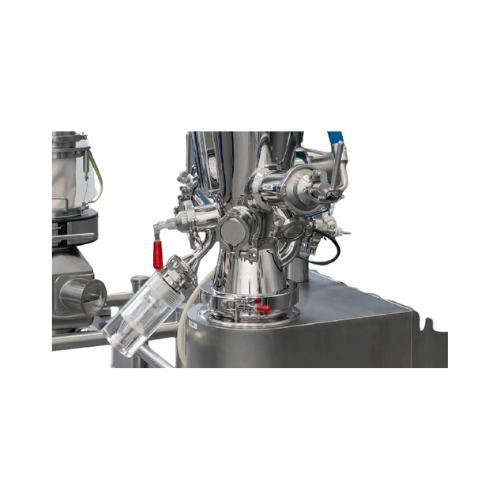

The BUCK® Sampler and Hicoflex® Sample Taking system from GEA combines innovative split valve technology and high containment mechanisms to support pharmaceutical production lines. This system is designed for gravity-based sampling applications, maintaining full containment of active powders throughout processes such as granulation and drying. It excels in providing contamination-free handling, crucial for maintaining product integrity in pharmaceutical tablets and powdered drugs.

The BUCK® Sampler features a secure docking mechanism that creates a seamless seal without interrupting the production process, while the Hicoflex® technology offers disposable, high containment sampling for added safety. This equipment is ideal for continuous and manual operations, integrating smoothly into existing production methodologies.

Constructed for robustness and chemical compatibility, it offers multiple material options to ensure durability across various environments. By meeting stringent GMP and FDA standards, it ensures compliance with industry regulations. Additionally, the system supports easy cleaning and maintenance, reducing downtime and supporting high-efficiency operations. GEA provides engineering support to customize configurations, ensuring a perfect fit for specific production requirements.

Benefits

- Ensures contamination-free sampling, protecting product quality and operator safety.

- Seamlessly integrates into existing systems, minimizing production interruptions.

- Reduces labor and cleaning time with easy-to-maintain components.

- Meets GMP and FDA standards, ensuring regulatory compliance.

- Supports diverse process needs with customizable configurations and material options.

- Applications

- Active powders, Solid dosage materials, Pharmaceuticals

- End products

- Powdered drugs, Pharmaceutical tablets, Active pharmaceutical ingredients (apis), Encapsulated medications, Solid oral dosage forms

- Steps before

- Steps after

- Input ingredients

- active powders, bulk material, solid dosage material

- Output ingredients

- process sample, contained sampling device, Hicoflex® Sample Bag

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Sample Volume

- 5 ml

- Containment Level

- Fully Contained

- Pressure Resistance

- Process-related

- Docking System

- Secure Seal

- Working Mechanism

- Gravity-based process sampling

- Integrated Steps

- Docking, Sampling, Undocking

- Automation Level

- Manual / PLC

- Contamination Prevention

- Fully contained sampling process

- Pressure Resistance

- Process-related pressure resistance

- Cleaning Method

- Fully disposable components (Hicoflex®)

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Sampler Type

- BUCK® Sampler

- Sampler Technology

- Split valve technology

- Sampling Method

- Gravity-based

- Sampling Volume

- Approx. 5ml

- Samper Port Closure

- Spring-loaded cover

- Sample Containment

- Fully contained process

- Docking Method

- Screwed connection

- Sampler Port

- Secure seal

- Disposable Sampler Type

- Hicoflex® Sample Bag

- Interface Type

- Hicoflex® Adaptor

- Discharge Method

- Contained transfer

- Control panel type

- Digital / HMI

- Integration possibilities

- With existing process systems

- Sampler type

- BUCK® Sampler / Hicoflex®

- Port compatibility

- Standardized connection interfaces