Sterile isolator for cellular labeling

Ensure sterility and protection in cellular labeling processes with an isolator that maintains a controlled environment, eliminating the need for a cleanroom and safeguarding both operator and product integrity.

Ensures Sterility in Cellular Labeling and Material Handling

The PHL Series Sterile Isolator from Comecer is designed for precise cellular labeling and secure handling of radiopharmaceuticals within nuclear medicine and advanced therapy medicinal products (ATMP) sectors. It features a modular design with a laminar airflow chamber and negative pressure environment to maintain sterility and safety. Ideal for working with products like Zevalin and CAR-T therapies, the isolator efficiently supports processes such as cellular labeling and material transfer. It is equipped with a 7” touch-screen panel for monitoring operations and is easily integrated into existing workflows with its maneuverable wheeled base. Compliance with Radiation Protection Standards is ensured, and the isolator is configurable with glove types and sizes. Enhanced maintenance accessibility is provided through fully openable front walls, while cleaning is facilitated by an integrated system, supporting the isolator’s adherence to GMP standards.

Benefits

- Ensures sterility with a negative pressure environment, minimizing contamination risks.

- Streamlines operations by eliminating the need for dedicated cleanrooms, reducing setup costs.

- Enhances safety with interlock doors preventing direct external exposure.

- Facilitates flexible operation through modular design, adapting to various workflow needs.

- Simplifies maintenance with easy-access design for quick cleaning and routine servicing.

- Applications

- Cytostatic drugs, Cell, Radiopharmaceuticals, Regenerative medicine, Gene therapy, Cellular labeling, Atmp (advanced therapy medicinal products), Nuclear medicine

- End products

- Zevalin, Chimeric antigen receptor t-cell (car-t) products, Lutathera, Technetium-99m labeled compounds, Zolgensma, Blinatumomab, Dendritic cell vaccines, Kymriah, Xofigo, Luxturna, Atezolizumab, Strontium-89 chloride, Lymphoseek, Therasphere, Indium-111 labeled leukocyte cells, Yttrium-90 microspheres, Yescarta

- Steps before

- Laminar Flow Setup, Material Preparation, Sterilization, Environmental Monitoring

- Steps after

- Sterility Check, Quality Assurance, Material Documentation, Cleaning and Maintenance

- Input ingredients

- cytostatic drugs, cellular materials, radiopharmaceuticals, sterilizing agents

- Output ingredients

- sterile labeled cells, processed pharmaceuticals, marked cellular materials

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Modular design

- Yes

- Touch-screen operator panel

- 7”

- Laminar air flow working chamber

- Yes

- Negative pressure environment

- Yes

- Glove flanges

- 2 oval

- Material transfer sliding tray

- Yes

- Interlock system

- Yes

- Electric socket in chamber

- Yes

- Inflatable gaskets

- FDA-approved silicone

- Handling position

- Seated

- Front wall opening

- Tilted 6°

- Software regulated interlocks

- Yes

- Compliance with Radiation Protection Standards

- Yes

- Modular design

- Flexible configuration

- Automation level

- Touch-screen operator panel

- Material transfer system

- Sliding tray and pre-chamber

- Glove change safety

- Ambidextrous gloves with double groove

- Pre-chamber door interlock

- Tightness system with inflatable gaskets

- Work chamber accessibility

- Front wall can be opened

- Mobility

- Mounted on wheels

- Cleaning accessibility

- Front wall opens completely

- Sterility assurance

- Safety interlocks prevent contamination

- Monitoring capability

- Large windows for observation

- Chamber size

- Large enough for operations in seated position

- Pressure regulation

- Negative pressure handling environment

- Cleaning method

- Performed with gloves

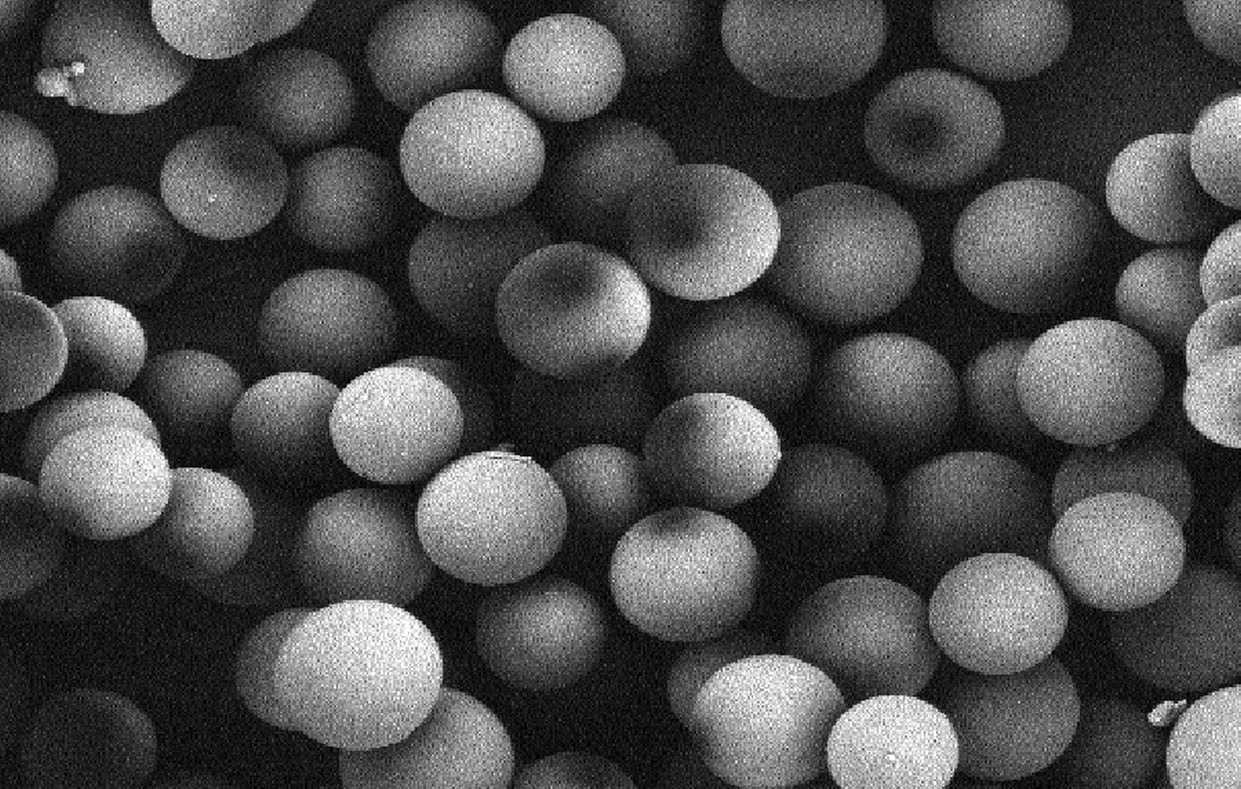

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- FDA Materials

- FDA-approved silicone

- Modular design

- Yes

- Touch-screen operator panel size

- 7 inches

- Airflow type

- Laminar air flow

- Chamber pressure

- Negative Pressure

- Mounted system

- On wheels

- Pre-chamber door type

- Manual tempered glass with tightness system

- Main chamber door mechanism

- Interlock system

- Glove material

- Ambidextrous gloves, customizable

- Front wall mechanism

- Gas springs with perimeter inflatable gaskets

- Modular design and flexible configuration

- Yes

- Control panel type

- 7” touch-screen operator panel

- Glove material and size

- Customizable according to customer requirements

- Front wall opening

- Complete with gas springs and adjustable tilt

- Material transfer door system

- Interlock tightness with inflatable gaskets