Automatic docking system for bulk powder handling

Optimize docking precision and ensure seamless alignment in bulk powder handling with this advanced system, designed to overcome manual handling limitations in high-scale production.

Automates Docking and Ensures Precise Alignment

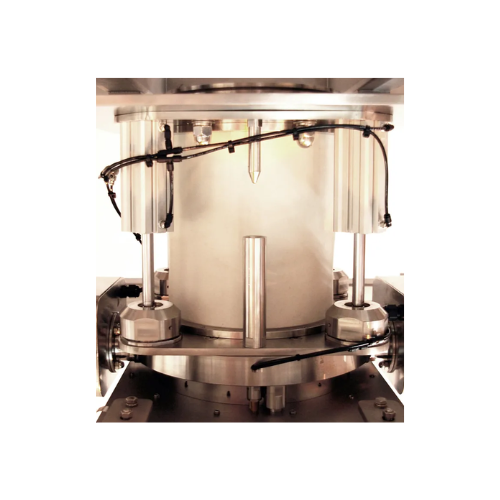

The PowerDock™ from ChargePoint Technology is a fully automatic docking system designed to enhance the efficiency and accuracy of bulk powder handling in pharmaceutical, battery, and chemical industries. Uniquely engineered to correct lateral misalignment, the system ensures precise docking and alignment by automatically raising and lowering the active unit. This makes it especially adaptable for environments where manual handling is not feasible due to hazardous conditions or production scale. PowerDock™ facilitates containment through a flexible EPDM connector that compensates for vertical movements, while guide pins and sleeves ensure consistent alignment. This system supports valve sizes from DN100 (4”) to DN300 (12”) with product contact materials, including 316L stainless steel and EPDM, accommodating industry-specific needs. Pneumatic and electrical proximity sensors contribute to its seamless integration in automated processes, offering reliable performance across multiple applications such as pharmaceutical tablet production, lithium-ion battery cathode manufacturing, and active pharmaceutical ingredient (API) processing.

Benefits

- Enhances production efficiency by automating docking processes, reducing manual labor.

- Ensures precise alignment to minimize powder spillage and maintain product quality.

- Provides consistent containment, reducing risk in hazardous environments.

- Adapts to a wide range of process equipment with versatile compatibility.

- Increases operational safety with integrated pneumatic and electrical sensors.

- Applications

- Containment solutions, Pharmaceutical powder, Batteries, Fine chemicals

- End products

- Pharmaceutical tablets, Lithium-ion battery cathodes, Active pharmaceutical ingredients (api), Fine chemical intermediates, Catalysts

- Steps before

- Powder Preparation, Material Transport, Process Alignment

- Steps after

- Packing, Process Equipment Cleaning, Container Sealing

- Input ingredients

- Output ingredients

- Market info

- Chargepoint Technology is known for its expertise in designing and manufacturing high containment and sterile transfer solutions for pharmaceutical and biopharmaceutical industries, particularly in powder containment and aseptic transfer systems.

- Valve Size Compatibility

- DN100 (4”) to DN300 (12”)

- Product Contact Materials

- 316L and EPDM

- Connection to Active

- Direct to active or Tri-Clamp

- Connection to Process

- Tri-Clamp or process specific

- Sensors

- Pneumatic or electrical proximity

- Cylinders

- Pneumatic

- Automation

- Fully automatic

- Automation level

- Fully automatic

- Docking Accuracy

- Automatic repeatable

- Misalignment Correction

- Lateral and vertical

- Docking Mechanism

- Automated raising and lowering

- Containment

- Maintained during operation

- Guide System

- Integral guide pins and sleeves

- Product contact materials

- 316L and EPDM

- Connection type

- Direct to active or Tri-Clamp

- Connection to process

- Tri-Clamp or process specific

- Valve size compatibility

- DN100 (4”) to DN300 (12”)

- Connection to Active

- Direct to active or Tri-Clamp

- Connection to process

- Tri-Clamp or process specific

- Sensor type

- Pneumatic or electrical proximity