Sterile transfer chamber for pharmaceutical components

Ensure the sterility of your components rapidly with an enclosed chamber that achieves up to a 6-log reduction in contaminants in seconds, ideal for safeguarding high-purity manufacturing processes.

Sterilizes and Transfers Components into Cleanrooms

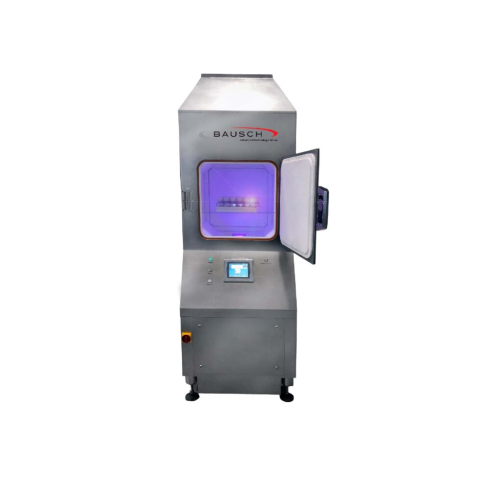

The Type 411 from BAUSCH Advanced Technology Group is an engineered-to-order UV sterile transfer chamber designed for the pharmaceutical and biotech industries. The chamber uses pulsed ultraviolet radiation to achieve up to a 6-log reduction in surface contaminants, ensuring that components like sterile IV bags, pre-filled syringes, and vial packs remain contaminant-free as they transition into cleanrooms or isolators. Capable of both stand-alone and in-line integration, the Type 411 handles the complete decontamination cycle, including loading and unloading, within 20-60 seconds. With 100% cycle verification, it enhances process reliability and compliance with GMP standards. The system’s automated operation minimizes manual intervention, making it an efficient addition to any high-speed aseptic fill-finish production line. Available in durable materials suited for sterile environments, it supports CIP processes for straightforward maintenance. Customization options are available to meet specific operational and space requirements, backed by comprehensive engineering support from BAUSCH.

Benefits

- Ensures high-level decontamination with a quick 20-60 second cycle, reducing production bottlenecks.

- Enhances operational reliability with 100% cycle verification for consistent sterile transfer.

- Facilitates seamless integration into existing production lines, increasing overall process efficiency.

- Minimizes manual handling, reducing contamination risk and labor requirements.

- Customizable design supports specific production needs and spatial constraints, offering scalable solutions.

- Applications

- Sterile containers, Biopharmaceuticals, Aseptic fill-finish packaging, Pharmaceuticals

- End products

- Sterile ophthalmic solutions, Aseptic vaccine doses, Vial packs, Pre-filled syringes, Ampoules, Monoclonal antibody formulations, Sterile iv bags

- Steps before

- Loading, Component Placement

- Steps after

- Unloading, Next Processing Stage

- Input ingredients

- components, containers, operator, robotic arm

- Output ingredients

- decontaminated components, decontaminated containers, sterile transfer

- Market info

- Bausch Group is known for its precision engineering and manufacturing of custom industrial equipment, specializing in engineered-to-order solutions for various industries, prioritizing quality, innovation, and client-specific needs.

- Process

- Sterilize

- Cycle time

- 20–60 seconds

- Exposure time

- 5–30 seconds

- Log reduction

- Up to 6-log

- Automation

- Available as stand-alone or in-line machine

- Verification

- 100% on every cycle

- Working mechanism

- Pulsed ultraviolet radiation light

- Integrated steps

- Loading, Exposure, Unloading

- Automation level

- Manual / Robotic Arm Integration

- Batch vs. continuous operation

- Batch

- Cycle time

- 20-60 seconds

- Cleaning method

- Not specified

- Energy Efficiency

- Not specified

- Verification method

- 100% verification on every cycle

- Biological compatibility

- Suitable for pharmaceutical environments

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Cleanability

- Easy to clean surfaces

- Usage

- Standalone / In-line machine

- Chamber design

- Enclosed sterile transfer chamber

- Cycle time

- 20-60 seconds

- Exposure Time

- 5-30 seconds

- Control panel type

- Available as stand-alone or in-line machine

- Integration possibilities

- Robotic arm loading