Slide valves for flow interception in powder and granular materials

Effectively manage the flow of powdery and granular materials with high resistance to abrasion and seamless integration into your existing systems, ensuring optimal sealing and operational safety.

Intercepts and Controls Material Flow

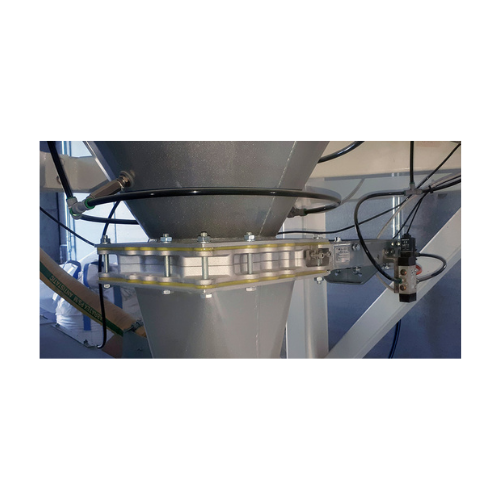

The VL Slide Valve from WAMGROUP is uniquely designed for efficient material flow control in various industrial applications. Utilizing a robust two-piece frame, partly coated with WAM’s SINT engineering polymer, these valves minimize abrasion and eliminate the need for flange gaskets. They intercept granular and powdery materials in processes such as flour milling, cement production, and wastewater treatment. Available in manual, pneumatic, and electric operations, the valves integrate seamlessly into production lines, featuring compact dimensions, particularly the VLS version, which includes a pneumatic actuator. Constructed from either carbon or stainless steel, with options for food-grade polymers, the valves ensure safe operation with an all-around dustproof seal. Compliant with industry standards and available in various geometries, the VL Slide Valve is versatile for horizontal or vertical installations, engineered to reduce maintenance with easily dismantled components.

Benefits

- Increases material handling efficiency with precise flow control.

- Enhances durability with abrasion-resistant SINT polymer components.

- Reduces maintenance time due to easy disassembly and reassembly.

- Ensures safe operation with fully sealed, dustproof design.

- Adapts to diverse industry applications with customizable configurations.

- Applications

- Cement, Lime, Animal feed, Detergents, Concrete production, Paint and varnish, Sugar processing, Rubber processing, Biscuit processing, Food processing, Solid waste handling, Flour milling, Gypsum, Plastics raw materials, Wastewater treatment, Fertilizers, Pharmaceuticals

- End products

- Ready-mix concrete, Biscuits, Laundry detergent powder, Pharmaceutical tablets, Sugar, Npk fertilizer granules, Cement powder, Paint emulsions, Lime powder, Gypsum boards, Milled grain, Treated wastewater, Flour, Refined sugar, Rubber sheets, Animal feed pellets, Compost, Plastic pellets

- Steps before

- Material Handling, Grinding, Purification, Conveying, Silo Filling

- Steps after

- Packing, Dust Filtration, Quality Inspection, Storage, Loading

- Input ingredients

- powdery materials, granular materials, bulk solids, fine powders, dust

- Output ingredients

- intercepted materials, controlled material flow

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Material Compatibility

- Powdery or granular materials

- Abrasion Resistance

- High

- Seal Type

- All-round dustproof seal lips

- Actuator Type

- Pneumatic / Manual / Electric

- Material

- Carbon or stainless steel, SINT polymer

- Mounting Orientation

- Horizontal or Vertical

- Configuration

- Rectangular, square, circular

- Certification

- ATEX (optional)

- Valve Frame Coating

- SINT polymer composite

- Blade Material

- SINT polymer, Carbon steel, Stainless steel

- Automation

- Interchangeable actuators

- Operation Type

- Gravity or Conveying

- Working mechanism

- Slide valve with gravity or conveying based material interception

- Automation level

- Manual / Pneumatic / Optional Electric

- Cleaning method

- Manual cleaning

- Batch vs. continuous operation

- Continuous inline operation

- Changeover time

- Quick assembly and disassembly due to limited parts

- Energy efficiency

- Low energy usage due to pneumatic operation

- Abrasion resistance

- High

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Available in stainless steel for corrosion resistance

- Density/particle size

- Compatible with powdery or granular materials

- FDA Materials

- Yes

- CE marking

- Available

- ATEX certification

- Available

- Frame Material

- Carbon Steel / Stainless Steel

- Coating Material

- SINT Engineering Polymer

- Blade Material

- SINT Engineering Polymer / Carbon Steel / Stainless Steel

- Valve Shape

- Square / Circular / Rectangular

- Integrated Actuator

- Pneumatic

- Mounting Orientation

- Horizontal / Vertical

- Footprint

- Compact

- Actuator Type

- Manual / Pneumatic / Electric gear motor

- Frame Material

- Carbon Steel / Stainless Steel

- Blade Material

- SINT polymer-coated / Carbon Steel / Stainless Steel

- Cross Section Type

- Rectangular / Square / Circular

- ATEX Certification

- Available

- Food-Grade Compliance

- FDA/EN-approved on request