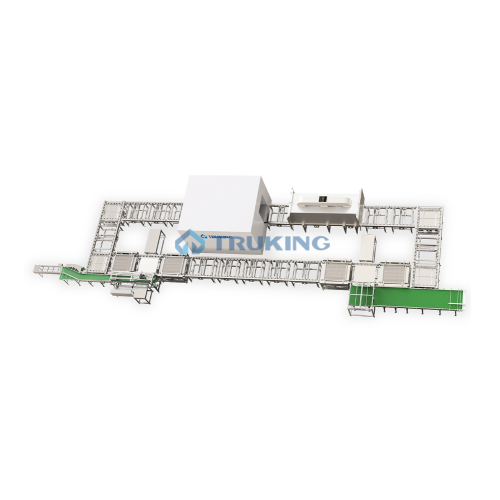

Robotic sterilization logistics system

Ensure seamless aseptic transfers across production stages with this robotic logistics system, eliminating manual intervention while maintaining stringent compliance with global regulations.

Performs Lyophilization for Biopharmaceutical Applications

The Biopharmaceutical Freeze Dryer System from TRUKING Technology Limited provides an efficient solution for lyophilization in sensitive applications like vaccines and insulin injections. It employs an advanced multi-stage freeze-drying process to ensure precise moisture control. Designed for integration into continuous production lines, the system supports automation with a PLC-controlled interface and remote monitoring. Capable of processing a wide range of product types, it maintains energy efficiency with optimized motor controls. Constructed from corrosion-resistant materials, the system adheres to stringent cGMP and FDA standards. Ease of maintenance is ensured with an integrated CIP system for contamination-free cleaning and custom engineering options available to meet specific throughput and configuration needs.

Benefits

- Enhances product stability by ensuring precise moisture control.

- Minimizes operational disruptions with continuous automated operation.

- Reduces energy costs through optimized motor efficiency.

- Complies with cGMP and FDA standards for seamless regulatory adherence.

- Facilitates quick cleaning, reducing downtime with an integrated CIP system.

- Applications

- Solid preparations, Pre-filled syringe, Injectable, Lyophilization, Oral preparations, Oral liquids, Biopharmaceuticals, Traditional chinese medicine, Ampoule, Bioreactors, Bfs (blow-fill-seal), Diagnostic reagents

- End products

- Vaccines, Single-dose vaccines in pre-filled syringes, Lyophilized cancer drugs, Vitamin c ampoules, Herbal extract capsules, Liquid antacids, Liquid cough syrup, Covid-19 test kits, Granulated traditional chinese medicine, Antiseptic bfs eye drops, Insulin injections

- Steps before

- Purification, Extraction, Concentration, Drying, Bioreactor System Preparation

- Steps after

- Sterilization, Packing, Inspection, Leakage Testing, Tablet Pressing

- Input ingredients

- ampoules, vials, soft bags, glass bottles, plastic bottles, bioengineering raw materials, traditional Chinese medicine ingredients, liquid preparations, diagnostic reagents

- Output ingredients

- freeze-dried products, filled ampoules, filled vials, filled soft bags, filled glass bottles, bioreacted products, purified extracts, oral liquid products, lyophilized products

- Market info

- Truking is known for manufacturing engineered-to-order pharmaceutical equipment, specializing in liquid and solid preparation systems. They have a strong reputation for innovation and quality in the pharmaceutical machinery sector.

- Automation

- Fully Servo, Robotic system

- Compliance

- GAMP, cGMP, FDA

- Product Flow

- Customized based on customer’s floor plan

- Digitization

- Industry 4.0 ready

- Manual Intervention

- Zero dependency

- Ergonomic Design

- Excellent product handling

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customized per customer floor plan

- Product handling

- Ergonomic design with robotic system

- System type

- Fully Servo, Robotic

- Buffer areas

- Sufficient buffer provided

- Control panel type

- HMI, Touchscreen

- Integration possibilities

- SCADA, PLC

- Customization of robotic system

- Fully customized logistic system

- Product flow customization

- According to customer’s floor plan and process

- Servo,Robotic system

- Fully Servo, Robotic system employed