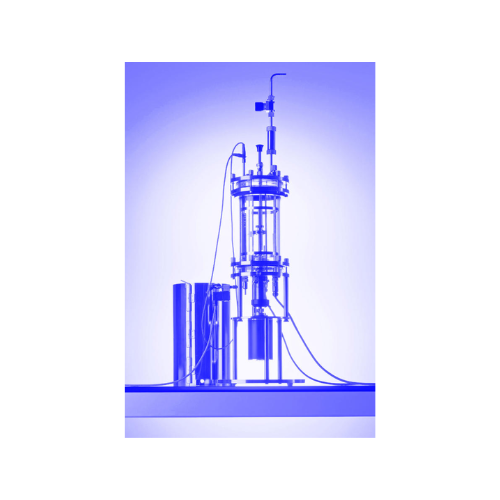

Lab-scale in-situ sterilizable bioreactor

Ensure precision in your laboratory and pilot projects with this bioreactor, designed for seamless sterilization, mixing, and control, facilitating efficient scale-up from benchtop experiments to full production.

Sterilizes, Mixes, and Controls Bioprocesses

The KLF from Bioengineering AG is an in-situ sterilizable lab and pilot-scale glass bioreactor designed for precision in biopharmaceutical and chemical research applications. What sets this equipment apart is its ability to facilitate seamless batch, fed-batch, and perfusion processes, utilizing BioSCADA software for sophisticated control and data visualization. Capable of processing 1.6 to 2.5 liters, it’s ideal for developing monoclonal antibodies, insulin, and probiotic beverages. The bottom-drive mechanism supports efficient mixing with Rushton and propeller stirrers. Equipped with advanced probes for precise measurement of pH, dissolved oxygen, and temperature, the KLF ensures rigorous process control. With customizable gas and pump modules, it promises flexibility and scalability. Its compact, modular design supports easy scale-up and scale-down, reducing development time and cost. Designed with compliance in mind, it adheres to GMP standards and includes a CIP system for effortless maintenance. The bioreactor’s robust materials and efficient energy use make it a reliable choice for modern labs.

Benefits

- Enhances process efficiency with precise control, minimizing product variability.

- Reduces contamination risk through in-situ sterilization, ensuring product safety.

- Supports scalable bioprocessing, optimizing transition from R&D to production.

- Simplifies integration with existing systems via adaptable BioSCADA software.

- Minimizes operational costs with robust construction and energy-efficient design.

- Applications

- Homeopathy, Food and nutritional products, Fine chemicals, Alternative medicine, Cosmetics, Biopharmaceuticals

- End products

- Perfume essences, Insulin, Active pharmaceutical ingredients (apis), Monoclonal antibodies, Vitamin supplements, Homeopathic tinctures, Herbal extracts, Probiotic beverages

- Steps before

- Media Preparation, Buffer Preparation, Sample Preparation

- Steps after

- Data Analysis, Cleaning In Place (CIP), Documentation, Maintenance

- Input ingredients

- media, buffer, cells, nutrients, gases, antifoam

- Output ingredients

- biomass, metabolites, exhaust gases, waste products

- Market info

- Bioengineering is known for its expertise in designing and manufacturing customized bioreactors and fermenters, serving the biotechnology and pharmaceutical industries. They are reputed for high-quality, engineered-to-order solutions and innovative process technologies.

- Processing capacity

- 1.6 / 2.0 / 2.5 liters

- Vessel Material

- Glass or stainless steel

- Drive Type

- Bottom drive with axial face seal or magnetic clutch

- Types of Stirrers

- Rushton, propeller, pitched-blade stirrers

- Ventilation System

- Venting pipe, ring sparger, sinter sparger, bubble-free gassing

- Temperature Control

- Electrical heating, cooling fingers

- Measurement and Control

- Speed, temperature, pH, pO2, antifoam/level, redox, OD, weight, exhaust analysis

- Gas Modules

- Up to 6 individual gassing lines with pulsed valves or mass-flow controllers

- Pump Modules

- Up to 6 pumps integrated and one external pump

- Software Control

- BioSCADA

- Configuration Control

- Up to 6 bioreactors with a single control unit

- Sterilization method

- Electrical heating

- Batch vs. continuous operation

- Batch / Fed-batch / Perfusion

- Automation level

- SCADA

- Clean-in-place (CIP) capability

- In-situ sterilizable

- Space efficiency

- Minimal space requirements

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Vessel material

- Glass or stainless steel