200l sterile tank liners for bioprocessing

Streamline your bioprocessing operations by eliminating tank cleaning steps and reducing contamination risks with our sterile tank liners, designed for efficient containment and hydration of liquid and powdered media.

Facilitates Hydration and Containment in Bioprocessing

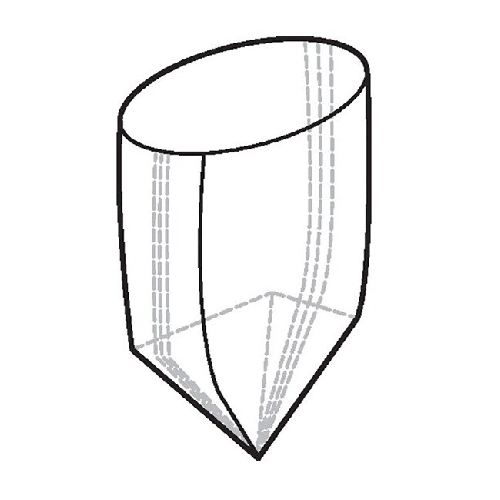

The HyPerforma™ 200L Tank Liner from Thermo Scientific offers a sterile solution for biopharmaceutical and chemical industries, designed to minimize bioburden and cross-contamination. Constructed from CX3-9 multi-layer plastic film, it suits batch processing activities in cleanrooms, enhancing hydration, pooling, and containment of non-sterile solutions and powdered media. Manufactured in an ISO 7 environment, these liners eliminate extensive cleaning requirements, integrating smoothly into pre-processing and processing operations with manual handling. Ideal for producing monoclonal antibodies, recombinant proteins, and buffer solutions, it supports efficient material management in laboratory and industrial settings, while meeting stringent cGMP and irradiation sterilization standards for compliance assurance.

Benefits

- Reduces cleaning time and costs by eliminating post-use cleaning of reusable containers.

- Minimizes risk of product contamination through sterile, single-use design.

- Ensures compliance with GMP standards, supporting regulatory requirements.

- Facilitates fast processing cycles, enhancing production efficiency.

- Supports flexible operation in biotech and pharmaceutical applications, adapting to various production needs.

- Applications

- Powdered media hydration, Non-sterile solutions, Cell culture media, Biopharmaceuticals, Buffers, Pharmaceuticals

- End products

- Sterile injectables, Vaccines, Buffer solutions, Monoclonal antibodies, Cell culture growth media, Biopharmaceutical drug formulations, Non-sterile liquid formulations, Hydrated powdered media, Recombinant proteins

- Steps before

- Hydration of powdered media, Preparation of non-sterile solutions, Preparation of buffers, Pooling of solutions

- Steps after

- Sterilization, Storage, Distribution, Usage in bioprocessing

- Input ingredients

- powdered media, buffers, non-sterile solutions, fluids

- Output ingredients

- hydrated media, pooled solutions

- Market info

- Thermo Fisher Scientific is renowned for providing innovative scientific instruments, laboratory equipment, and engineered-to-order solutions across various industries, esteemed for their high-quality products and expertise in life sciences, pharmaceuticals, and biotechnology sectors.

- Capacity

- 200 L

- Material

- Plastic

- Sterilization Method

- Irradiated

- Sterility

- Sterile

- Cleanroom Classification

- ISO 7

- Film Description

- CX3-9

- Outer Packaging

- Strong cardboard cartons

- Protective Inner Packaging

- Packed and sealed in two independent layers

- Sterilization Method

- Irradiated

- Open Top Design

- Maximum Recovery

- Bioburden Minimization

- ISO 7 Cleanroom

- Construction Environment

- cGMP Conditions

- Mobility Option

- Drum Dolly Available

- Post-use Cleaning

- Eliminated

- Biological compatibility

- Sterile

- Cleanability

- Eliminates post-use cleaning

- ISO Classification

- ISO 7

- Tank capacity

- 200 L

- Material

- Multi-layer plastic film (CX3-9)

- Open top

- Yes

- Discharge method

- Top drain

- Outer Packaging

- Strong cardboard cartons

- Inner Packaging

- Packed and sealed in two independent outer layers

- Sterilization Method

- Irradiated

- Construction environment

- ISO 7 cleanroom