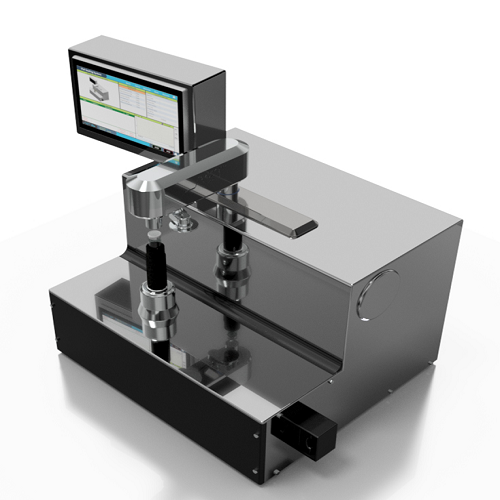

Bench-top vial sealing system for pharmaceutical use

Ensure precise sealing of pharmaceutical vials with a system designed for small batch production, maintaining sterility and stability crucial for high-value biopharmaceuticals and personalized medicine.

Seals and Caps Pharmaceutical Vials

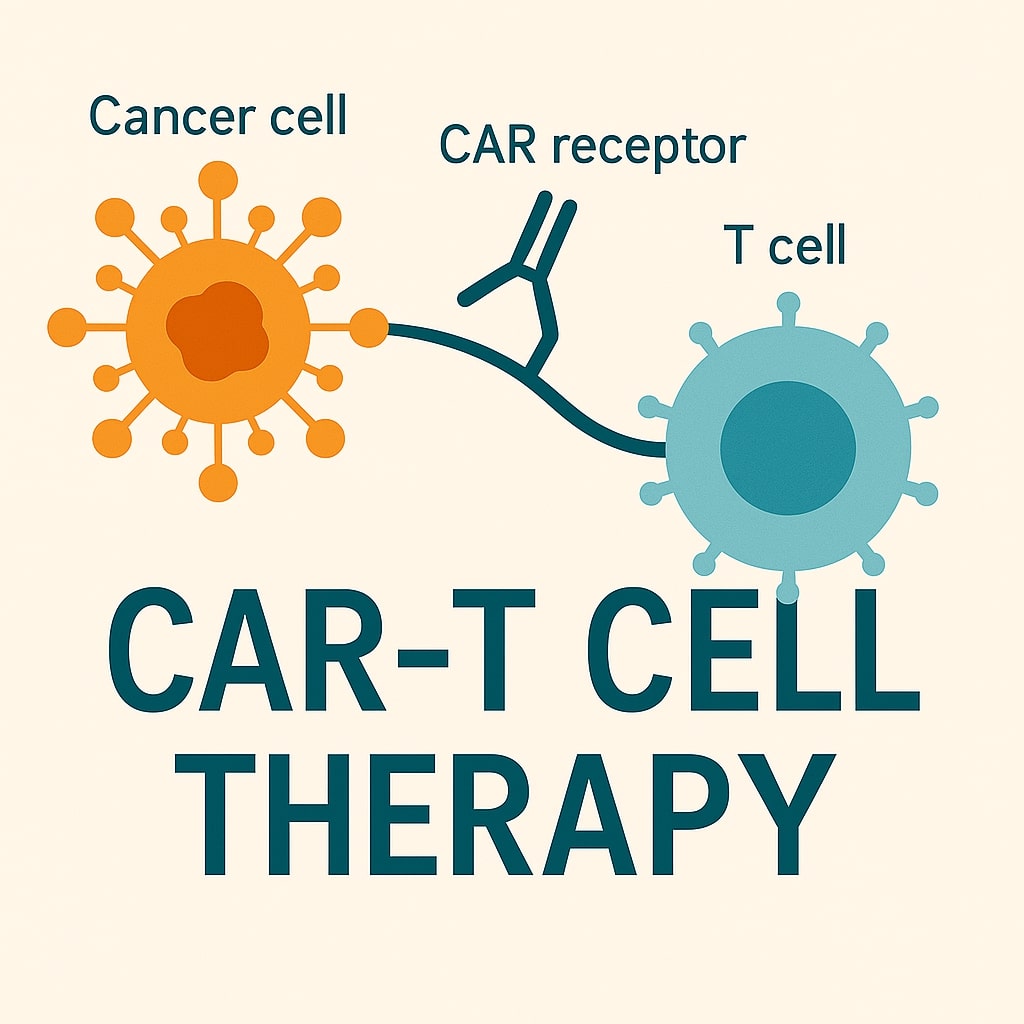

The Vial Sealing System (VSS) from AST is a semi-automatic bench-top machine ideal for sealing and capping pharmaceutical vials in small batch operations. This system ensures high-precision sealing by monitoring crucial parameters like compression force, maintaining sterility and closure integrity. Designed for applications in biopharmaceutical and clinical trial settings, it handles various vial sizes and cap types, making it versatile for mRNA vaccines, monoclonal antibodies, and gene therapy vials. The VSS integrates smoothly into cleanroom environments, featuring a compact, cGMP-compliant design compatible with isolators and bio-safety cabinets. The machine boasts a user-friendly ASTView interface for process monitoring and recipe creation, plus an optional Electronic Batch Report system to support regulatory compliance. Its disc-style, free-spinning sealing method minimizes particle generation and enhances vial aesthetics. Constructed from pharmaceutical-grade materials, the VSS offers easy maintenance and can be customized for non-standard container formats, ensuring seamless integration into diverse production lines.

Benefits

- Ensures high-quality vial seals, maintaining drug sterility and container integrity.

- Supports diverse pharmaceutical applications, accommodating various vial sizes and cap types.

- Minimizes particulate generation, enhancing product purity during the sealing process.

- Facilitates regulatory compliance with optional Electronic Batch Reporting.

- Compact design integrates seamlessly into aseptic environments, optimizing space utilization.

- Applications

- Personalized medicine, Compounding pharmacies, Orphan drug development, Clinical trial materials, Biopharmaceuticals, Vaccine development, Drug development, Pharmaceutical vials, Biotechnology products, Cell and gene therapy, Small batch commercial drug products, Stability studies

- End products

- Car-t cell therapies, Gene therapy vials, Niche pharmaceutical preparations, Hormone vials, Personalized cancer vaccines, Monoclonal antibodies, Liposomal formulations, Mrna vaccines, Stability test samples, Small-scale clinical trial doses, Viral vector-based vaccines, Recombinant proteins

- Steps before

- Filling, Stoppering

- Steps after

- Labeling, Packaging, Inspection, Storage

- Input ingredients

- vials, bottles, cartridges, rubber stoppers, aluminum caps, clean dry air

- Output ingredients

- sealed vials, sealed bottles, sealed cartridges, pharmaceutical aesthetic seal

- Market info

- AST is known for its expertise in designing and manufacturing customized engineered-to-order equipment for industrial applications, renowned for precision engineering, innovation, and reliable solutions tailored to meet unique customer specifications and industry standards.

- Size

- 780mm x 500mm x 640mm [31" x 20" x 25"]

- Container type

- Vials, Bottles, Cartridges

- Finish Size

- 8mm, 13mm, 20mm, 32mm

- Sizes (Diameter/Height)

- Ø12mm-47mm / 35mm-100mm

- Compression force

- Closed-loop compression force feedback

- Sealing Method

- Crimp or Press-fit

- Cap Type

- DIN standard with or without flip-top

- Sealing Method

- Disc Style

- Clean Air Utilities

- Clean dry air 6 bar, 56L/min free air

- Materials of Construction

- Pharmaceutical grade stainless steel, plastics, and elastomers

- Automation

- Semi-automatic

- Human-Machine Interface (HMI)

- ASTView on a 10" color touchscreen

- Batch vs. continuous operation

- Semi-automatic batch

- Automation level

- Semi-automatic

- Sealing process control

- Closed-loop compression force feedback

- Changeover time

- Tool-less format change parts

- Cleaning method

- Compatible with aseptic environments

- Automation level

- Intelligent interface with ASTView

- Particle generation

- Low particle generation

- Construction Material

- Pharmaceutical grade stainless steel, plastics, and elastomers

- Vial Type

- Serum or Lyo stopper options

- Process Type

- Small batch processing

- GMP Compliance

- cGMP

- Cleanroom Compatibility

- ISO 7 / ISO 8

- FDA materials

- Pharmaceutical grade stainless steel

- Machine Footprint

- 780mm x 500mm x 640mm [31" x 20" x 25"]

- Compact Footprint

- Aseptic isolators, biological safety cabinets or laminar airflow hood

- Control Panel Type

- 10" color touchscreen (ASTView)

- Control panel type

- ASTView high-resolution interface

- Integration possibilities

- Electronic Batch Report (EBR) System

- Customization of cap types and sizes

- DIN standard with or without flip-top

- Sealing method

- Disc Style

- Container options

- Vials, Bottles, Cartridges

- Finish Size

- 8mm, 13mm, 20mm, 32mm

- Tool-less format change parts

- Yes