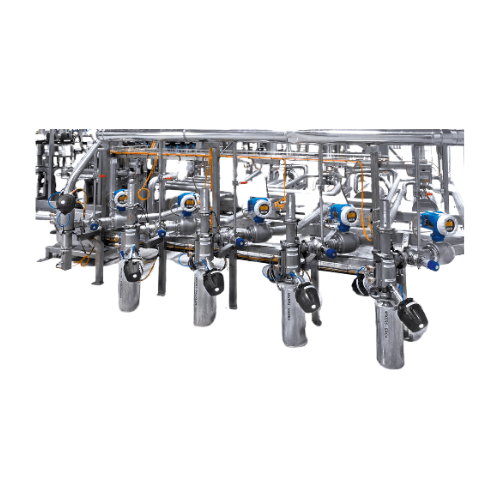

Product recovery system for hygienic applications

Efficiently reclaim valuable products from your production lines while minimizing waste and water usage with advanced product recovery systems, ensuring maximum output and sustainable operations in process-intensive sectors.

Recovers Product and Reduces Waste

The VARICOVER® Product Recovery and Pigging System by GEA is engineered to optimize the recovery of valuable products while minimizing waste in diverse sectors such as beverage, food, and pharmaceutical industries. This system excels in retrieving residual products from pipelines, utilizing pigging technology to ensure maximum yield and reduced effluent disposal. Common end-products include Jägermeister liqueur, skincare serums, and nutritional protein shakes.

The system offers versatility with fully automated, semi-automated, and manual operations, catering to various production capacities and setups. It seamlessly integrates into existing processes, enhancing overall efficiency with options for integration in ATEX-relevant areas. The use of water or nitrogen as pigging media ensures safe and efficient operation, while the system’s compliance with standards such as the 3A for the US market reaffirms its suitability for critical applications.

With its capability to handle liquid and gaseous products, this system reduces water and CIP media consumption, driving down operational costs. Material options available in stainless steel support durability and resistance to corrosion, making the system adaptable for different industrial environments. Customized configurations are facilitated by GEA’s engineering support, ensuring the equipment meets specific production requirements while simplifying cleaning and maintenance with integrated CIP capabilities.

Benefits

- Enhances product yield by recovering residuals, thus increasing profitability.

- Lowers effluent disposal costs through efficient waste reduction.

- Decreases water and cleaning agent usage, saving on operational expenses.

- Integrates seamlessly into existing systems, minimizing setup disruptions.

- Operates safely in ATEX zones, ensuring compliance and safety in hazardous environments.

- Applications

- Food, Gas, Beverage, Oil, Cosmetics, Chemical, Environment, Home and personal care, New food, Dairy, Pharmaceutical

- End products

- Fermented beverages, Essential oil extracts, Processed water for irrigation, Alternative protein products, Skincare serums, Nutritional protein shakes, Dairy-based yogurt drinks, Industrial solvents, Biodiesel, Jägermeister liqueur

- Steps before

- Mixing, Blending, Storage

- Steps after

- Cleaning, Packaging, Filling

- Input ingredients

- finished product, process lines, water, CIP media, product ingredients

- Output ingredients

- recovered product, reduced waste, reduced effluent, less wastewater

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Cleaning method

- Automated / Semi-automated / Manual

- Automation level

- Fully automated / Semi-automated / Manual operation

- Explosion Safety

- ATEX Categories II 2G Ex h IIB T3...T6 Gb XII 2D Ex h IIB T 135°C Db X

- Nominal Sizes

- DN25

- DN40

- DN50

- DN65

- OD 1“

- OD 1.5"

- OD 2"

- OD 2.5"

- OD 3"

- Pig Driving Media

- Water / Nitrogen

- Suitable Ex Zones

- 1

- 2

- 21

- 22 (inside and outside pipelines)

- Process Lines

- Product recovery

- Product Loss Reduction

- Yes

- Effluent Disposal Reduction

- Yes

- Water Consumption Reduction

- Yes

- CIP Media Consumption Reduction

- Yes

- Production Downtime Reduction

- Yes

- Working Mechanism

- Pigging System

- Automation level

- Fully automated / Semi-automated / Manual

- Operating environment

- ATEX Zones

- Product recovery efficiency

- High

- Cleaning method

- CIP / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Recovery Applications

- Food, Beverage, Pharmaceutical Industries

- Control panel type

- PLC-controlled, manual

- Automation level

- Fully automated, semi-automated, manual

- Integration possibilities

- Compatible with existing pipeline systems, ATEX-relevant areas

- Pig driving media

- Water, Nitrogen