Biodiesel Production Equipment

Find innovative production technology for making biodiesel and connect directly with world-leading specialists

The waste oils from cooking in your kitchen could be transformed to biodiesel. Oily biomass such as soybean, animal fats, or recycled grease make excellent feedstocks to produce high quality alternative transport fuel. Materials are combined with an alcohol in a transesterification reactor that converts the mass into crude biodiesel. The finished product is a low-sulfur, biodegradable fuel that can be used in its pure formulation or in petroleum diesel fuel blends.

Technology picks for biodiesel processing

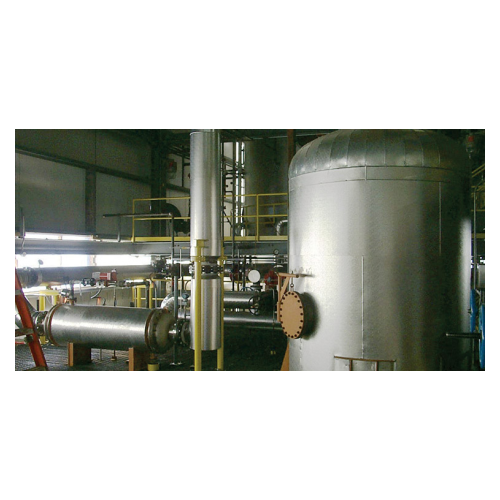

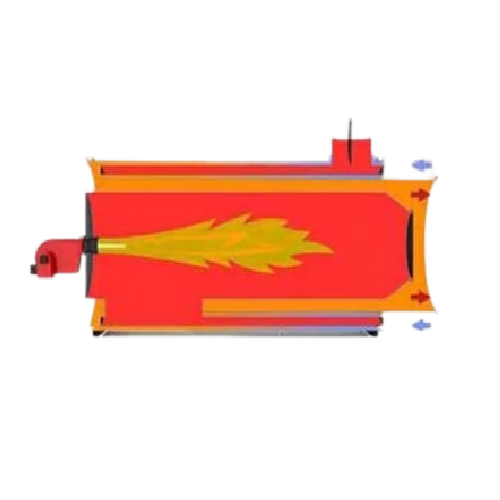

Biodiesel distillation process

Improve biodiesel quality by enhancing cold flow characteristics and removing impurities thro...

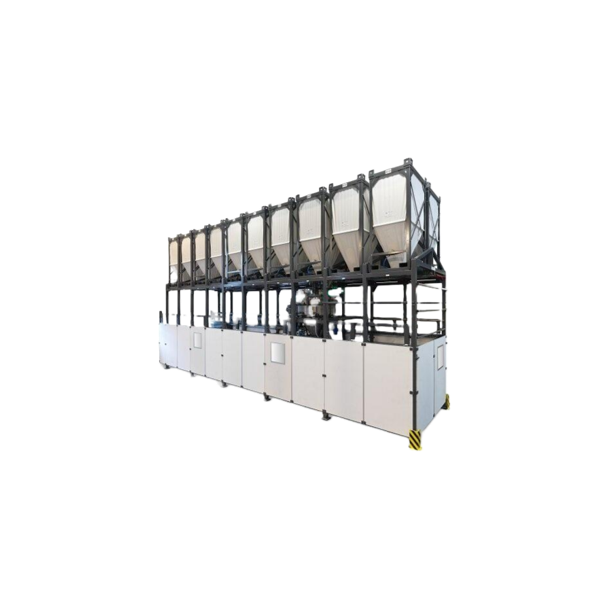

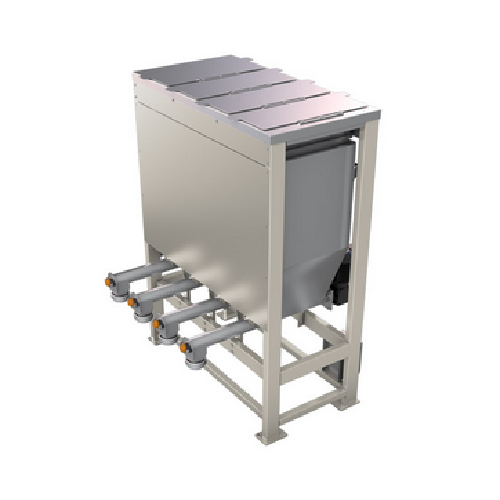

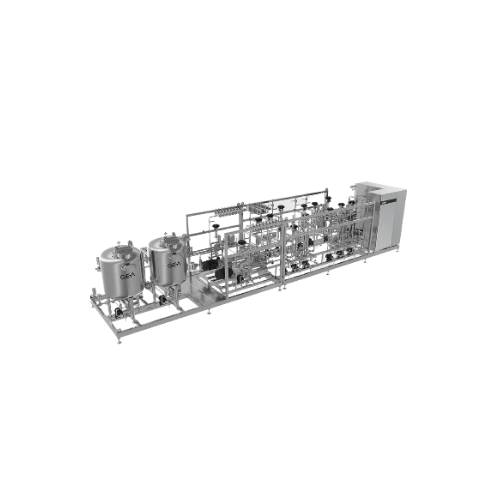

Biodiesel pretreatment system

Optimize your biofuel production by efficiently reducing impurities and unwanted components, e...

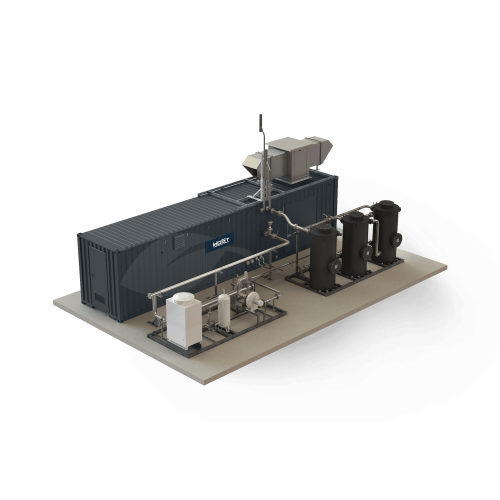

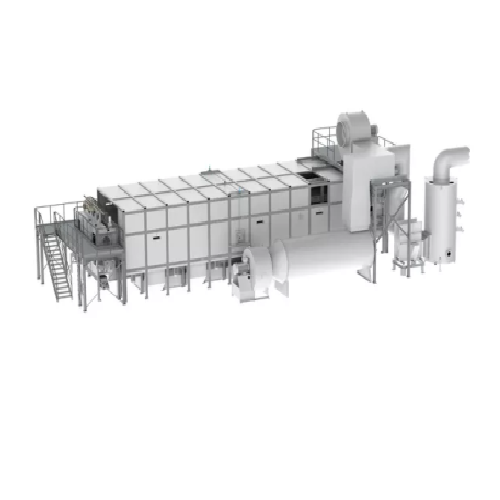

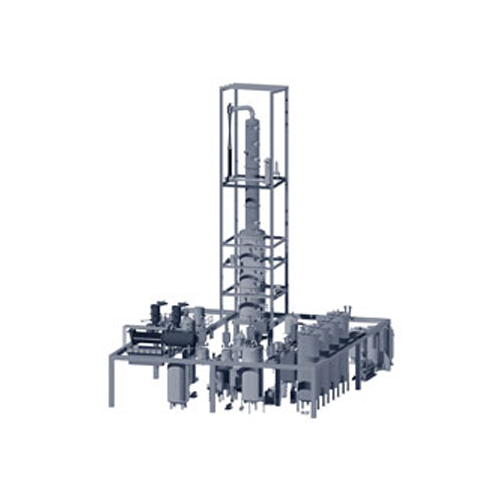

Production plant for biodiesel

As a biofuel producer, making biodiesel from several types of treated vegetable oils or anima...

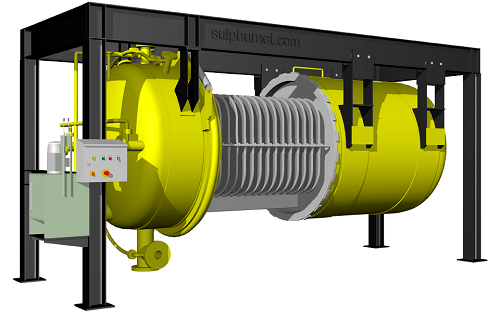

Glycerine manufacturing plant

Glycerol or glycerin is the major by-product generated in the biodiesel production process. Bu...

Select your biodiesel process

Tell us about your production challenge

Processing equipment to convert raw biodiesel into the finished product

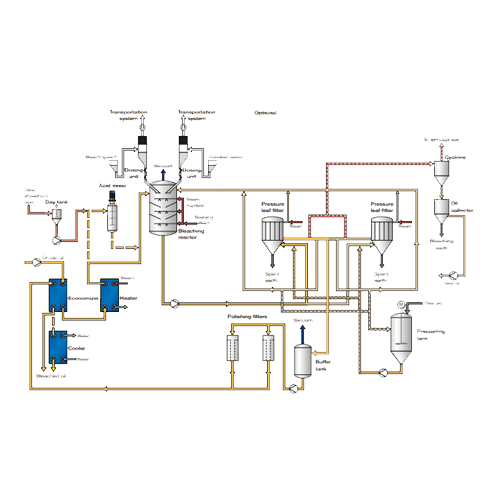

The transformation of organic waste into biofuel starts in the sanitization machine that deacidifies your base feedstock and degums it from wax content. This is when your biomaterial is ready to be pumped to the transesterification reactor and transformed into unrefined biodiesel.

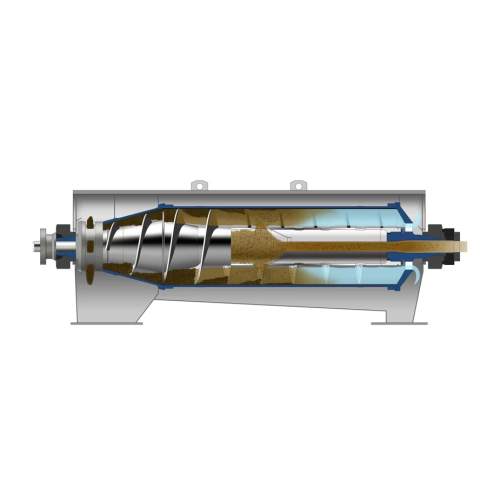

This chemical process forms glycerin that you then need to separate from the fuel using a centrifuge. The remaining liquid passes through a filtration system, leaving you with upgraded biodiesel at the other end.

Diesel blends raise the emissions bar

Biodiesel offers a range of advantages over standard diesel. Besides being a renewable fuel, it emits lower levels of toxics and contaminants. And, unlike diesel, it does not spout any sulfur dioxide.

Although pure biodiesel can be used with existing technologies, it is more widely used in concentrations with regular diesel. Most products on the market contain either a maximum of 5% biodiesel (B5) or up to 20% (B20).

Biodiesel gets the green light

Large vehicles like trucks, buses, and trains usually rely on diesel engines. Thus, making biodiesel processing a central plank of strategies to reduce greenhouse gas emissions in the transportation sector.

Oil-bearing biomass is being used in the same way to develop alternatives to fossil jet kerosene. Sustainable Aviation Fuel (SAF) is projected to increase from 5% of the global jet fuel mix in the early 2020s to almost 20% by 2040.

Processing steps involved in biodiesel making

Which biodiesel technology do you need?

Biofuel separator for marine applications

Efficiently separate and purify marine biofuels while meeting the stringent envi...

Separator for oil refining

Optimize your oil refining processes with a centrifugal separator that enhances purity by efficie...

Separators for cooling lubricants and industrial fluids

Efficiently separate complex oil-water mixtures and cooling lubri...

Clarifiers for biochemical separation

Achieve seamless liquid-solid separation with high-speed disk-type clarifiers, ensuri...

Sanitary cover for visual inspection

Ensure optimal hygiene and easy access in your production line with a transparent cove...

Vacuum cold trap for lab applications

Ensure efficient separation and purification in biopharmaceutical applications with t...

Laboratory automation software for distillation and extraction

Optimize your distillation and extraction processes with ...

Silo unloader for difficult products

Tackle challenging silo extractions with a robust unloading system designed for high-s...

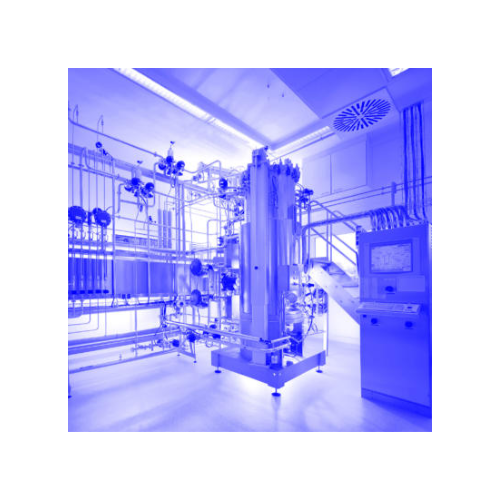

Sterilization in place fermentor for bioprocess applications

Optimize your fermentation processes with seamless integrat...

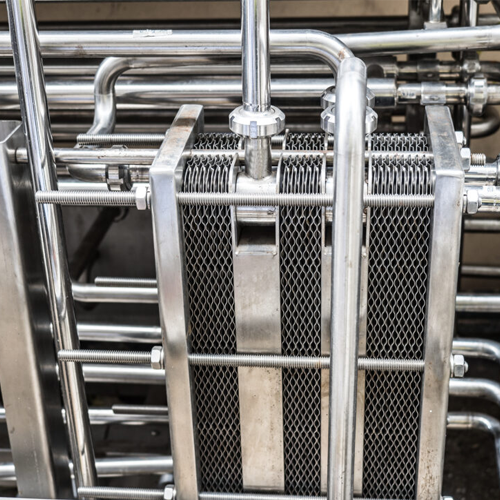

Mbr module for wastewater treatment

Optimize your wastewater management with efficient membrane bioreactors, designed to en...

Laboratory dispersion reactor for 10l batch processes

Enhance precision and efficiency in lab-scale liquid formulations w...

Biogas upgrader for high methane yield

Optimize biogas production by efficiently converting raw biogas into high-purity bio...

Sealless top-entry industrial mixer

Engineered for diverse industrial applications, this sealless top-entry mixer offers su...

High-speed cutting mill for versatile material comminution

Efficiently transform diverse materials like plastics, textil...

Biomass baler for woody biomass collection

Optimize woody biomass management with a mobile solution that reduces noise, du...

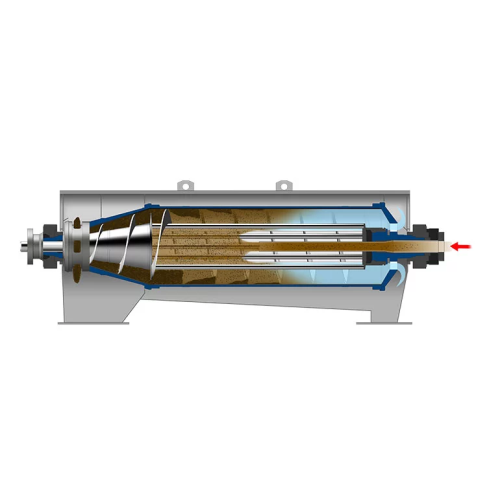

Decanter centrifuge for soft sediment separation

For operations dealing with soft, easy-flowing sediments, ensuring effici...

3-phase liquid separation solution

Achieve precise separation of liquids and solids to enhance product quality and streamli...

Centrifuge for plastics recycling

Enhance your recycling process with a centrifuge designed to efficiently separate and dew...

3 phase decanter centrifuge for industrial separation

Optimize your production line with efficient three-phase separation...

Industrial belt press for fruit and vegetable processing

Optimize your juice yield and reduce drying costs in starch and ...

Decanter centrifuge for wastewater treatment

Effectively manage waste streams and enhance resource recovery with this high...

Centrifuge for sewage sludge dewatering

Efficiently reduce sludge volume and cut disposal costs by harnessing effective dew...

Advanced sludge dewatering for sewage treatment plants

Optimize sludge dewatering with a centrifuge that enhances separat...

Mini bioreactor for cell culture and microbial process development

Achieve precise control and reproducibility in small...

Single-use bioreactors for microbial fermentation

Optimize high-density fermentation with advanced single-use bioreactor ...

High-speed centrifuge for biomass and particle harvesting

Achieve high-speed particle separation and biomass harvesting ...

Parallel bioreactor system for cell culture and microbiology

Optimize bioprocess development with a scalable system desi...

Industrial pasteurizer for dairy and beverage processing

Enhance product quality and safety with efficient heat treatment...

Stainless steel fermentation tanks

Optimize your fermentation efficiency with stainless steel tanks that provide precise te...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Laboratory mixer and dryer for solids

Enhance your laboratory capabilities with precision mixing and drying for small batch...

Portable process development unit for gas-liquid reactions

Optimize your gas-liquid reaction processes with a versatile,...

Pilot plant for highly viscous applications

Perfect for R&D, this pilot plant efficiently handles complex mixing and ...

Portable ethanol extraction processing lab

Accelerate your extraction process with a fully portable and compliant lab solu...

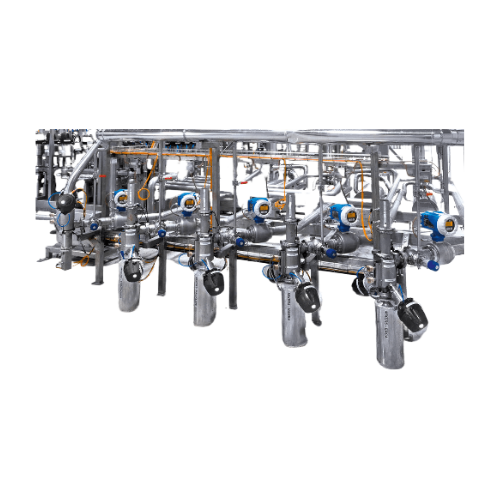

Filtration skid for ethanol extraction of cannabis and hemp oil

Enhance the clarity and color of your ethanol-extracted ...

Industrial rotary dryer for odor and emission control

For challenging drying applications with odor and emission concerns...

Flash dryer for surface moisture removal in powders

Optimize moisture removal in heat-sensitive materials with rapid, uni...

High performance heat transfer system

Enhance your production efficiency with a system that shortens cycle times by increas...

Thin film evaporator for temperature sensitive products

Need to purify temperature-sensitive compounds efficiently? Achie...

Oilseed cooker/conditioner for optimal seed preparation

Achieve consistent oil extraction and enhanced product quality wi...

Oil presses for oilseed extraction

Ensure efficient oil and protein extraction with specialized presses, enabling optimal s...

Vertical seed conditioning system for oil extraction

Ensure optimal oil yield and quality from oilseeds by employing a ve...

Oil and fat refining system

Ensure high-quality oil and fat production by efficiently removing contaminants such as phosphat...

Industrial oil bleaching process

Optimize your oil purification process with advanced bleaching technology, significantly en...

Continuous deodorizing for oils and fats

Achieve optimal purity and flavor in oils and fats with advanced continuous deodor...

Industrial oil degumming process

Achieve optimal oil purity and maximize yield with this advanced system designed to streaml...

Oil neutralizing technology for chemical refining

Achieve optimal purity and yield in oil processing with precise control...

Percolation extractor for high-volume vegetable protein extraction

Optimize extraction efficiency across diverse materi...

Continuous vacuum dryer for protein products

Achieve precise moisture control and maintain product functionality with low-...

Hemp Cbd oil extraction system

Achieve maximum CBD oil recovery while maintaining product purity with scalable extraction ca...

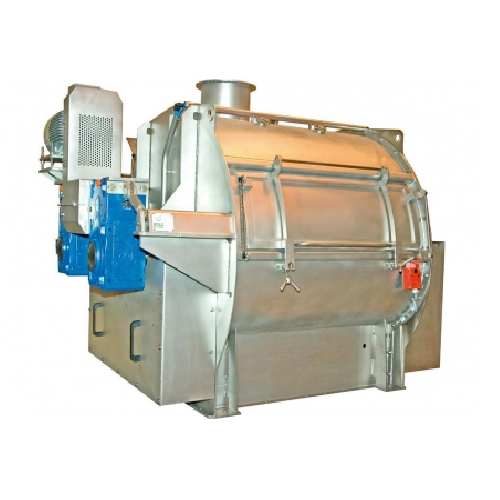

Efficient desolventization and toasting solution for oilseeds

Optimize solvent removal and toasting in your oilseed proc...

Efficient dryer-cooler for solvent-extracted meals

Optimize moisture control and energy efficiency in your production lin...

Mineral oil absorption system for solvent vapor recovery

Optimize solvent recovery and reduce atmospheric emissions with ...

High-volume oilseed extraction system

Achieve optimal extraction efficiencies with a versatile system that handles various ...

White flake desolventization for oilseed processing

Optimize your oilseed processing with a system designed to efficientl...

Zero effluent discharge system for solvent extraction plants

Eliminate wastewater in your solvent extraction process whi...

Seed hull removal and condition system

Optimize your seed processing efficiency by effectively removing hulls and foreign m...

Biodiesel distillation process

Improve biodiesel quality by enhancing cold flow characteristics and removing impurities thro...

Biodiesel pretreatment system

Optimize your biofuel production by efficiently reducing impurities and unwanted components, e...

Renewable diesel pretreatment system

Extend hydrotreater catalyst life and boost plant uptime by optimizing feedstock purit...

Dryer-cooler for solvent-extracted meal

Achieve optimal moisture and temperature control for solvent-extracted vegetable-oi...

Flash desolventization system for oilseed processing

Achieve rapid desolventization with minimal heat exposure, preservin...

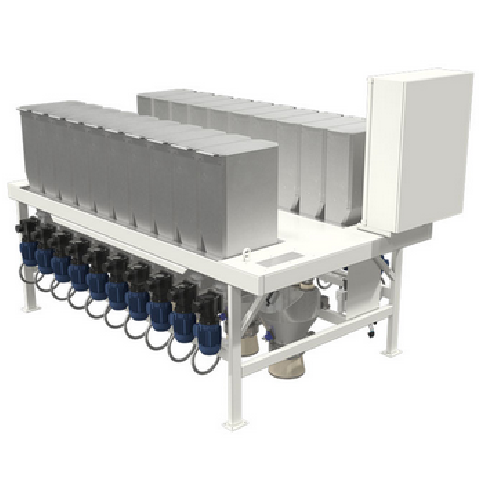

Accurate weighing system for micro ingredients

Ensure precise micro-ingredient dosing for batch operations with this versa...

Loss-in-weight scale for micro ingredient batching

Enhance precision in your production line with advanced micro ingredie...

Industrial circular coolers for uniform product cooling

Achieve consistent cooling across your product range with circula...

Hammermills for grinding tough products

Optimize particle size reduction with precision-designed hammermills that efficient...

Industrial moisture and temperature control conditioner

Optimizing moisture absorption and temperature management, this c...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial recirculating chiller for laboratory applications

For consistent distillation results, maintain accurate temp...

Lab-scale twin screw extruders for material development

Accelerate your formulation testing and material development with...

Synthesis gas cooler for partial oxidation of oil or natural gas

Optimize high-temperature gas streams efficiently by em...

Lab-scale fermentors for microbial cultivation

Optimize microbial cultivation with lab-scale fermentors designed for preci...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Custom pressure vessels and tanks

For industries demanding precise storage and processing, our tailor-made pressure vessels...

Shell and tube heat exchangers

Efficiently manage heat transfer in your production line with custom-engineered shell and tub...

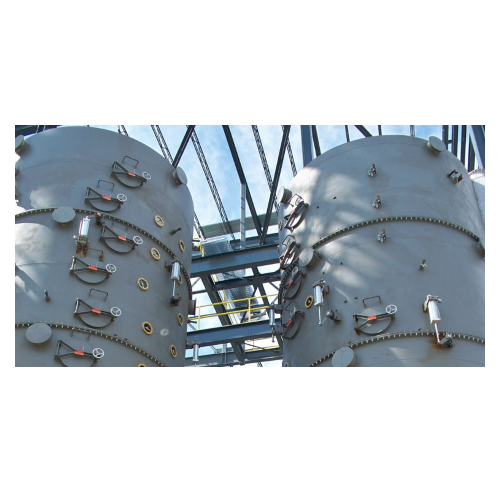

Industrial columns and towers for chemical processing

Optimize your chemical production with robust columns and towers, d...

Biomass drying solution

Achieve efficient and gentle biomass drying with innovative heat exchange technology, ensuring optima...

Industrial drum dryer for bulk solids

Optimize your production line with high-throughput drying for varied particle sizes, ...

Vegetable oil separator for high-quality oil processing

Achieve optimal separation of oils and fats with advanced centrif...

Decanter centrifuge for vegetable oil clarification

Maximize oil recovery and purity with advanced decanter centrifuge te...

Bleaching systems for edible oil refining

Achieve clarity and stability in your edible oils with cutting-edge bleaching sy...

Welded spiral heat exchangers for dirty or viscous fluids

Handle your toughest heat exchange challenges with minimal fou...

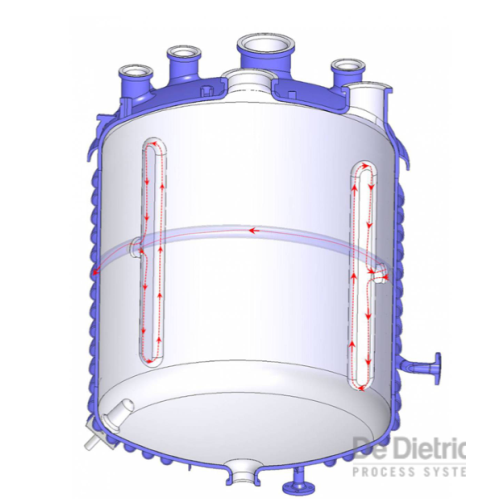

Dual-jacketed reactor for decarboxylation processes

Streamline your decarboxylation process with a dual-jacketed reactor ...

Controlled atmosphere muffle furnace

Achieve precise temperature and atmosphere control for critical processes like sinteri...

Customizable storage tanks for industrial use

Optimize your production with versatile storage tanks designed for precise c...

High pressure pumps for viscous fluid transfer

Optimize fluid transfer with high pressure pumps designed to handle viscous...

Product recovery system for hygienic applications

Efficiently reclaim valuable products from your production lines while ...

Single-stage centrifugal pump for heavy-duty applications

Optimize fluid handling with a high-efficiency centrifugal pum...

Compressor package for freezing and heat pump applications

Optimize your heating and cooling systems with high-efficienc...

Continuous in-line blender for home and personal care products

Achieve precision and flexibility in blending liquid mult...

Very high pressure homogenizer compression block

Experience reliable performance at extreme pressures with a compression b...

Falling film evaporator for temperature-sensitive products

Ensure consistent concentration and quality of heat-sensitive...

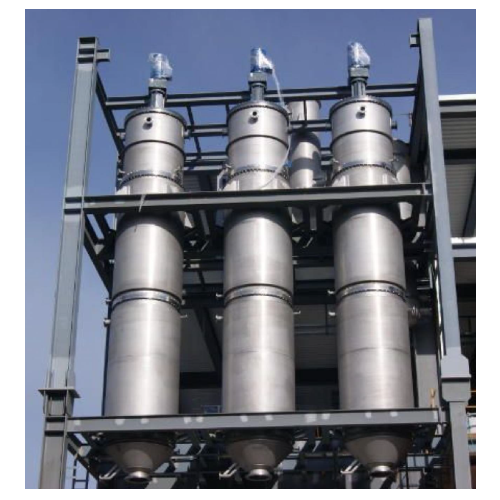

Mvr and Tvr heated distillation system

Achieve superior energy efficiency and reduced steam consumption in your distillatio...

Reboiler for distillation plants

Efficiently manage energy input and temperature control in your distillation processes with...

Industrial chiller with high part-load efficiency

Optimize your cooling processes with a versatile chiller designed for p...

Clarifying decanter for chemical processing

Optimize your clarification and dewatering processes with a versatile decanter...

Clarifying decanters for edible oil refining

Enhance your edible oil refining process with clarifying decanters that effic...

Industrial rapid turbulent mixer for homogeneous mixing

Achieve unparalleled homogeneity with rapid turbulent mixing, ess...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Manure treatment system for livestock breeding

Optimize waste-to-value processes with advanced systems designed to efficie...

Biogas plant screw press separators

Maximize your renewable energy output and processing efficiency with cutting-edge solid...

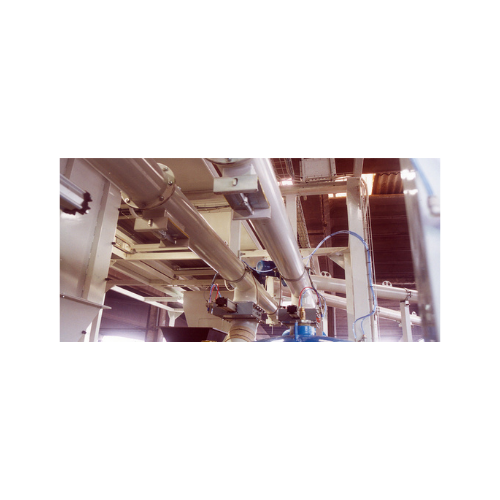

Bulk solids conveying systems

Efficiently move and manage bulk materials with precision and reliability, ensuring seamless i...

Biomass digester feeding system

Efficiently integrate biomass into your biogas production process with a system that seamles...

Hand wheel actuators for Vg slide valves

Effortlessly control flow interception in high-demand settings with these hand whe...

Wet spent grains pre-dewatering system

Optimize your brewery operations with a dewatering system that efficiently reduces m...

Centrifugal separators for liquid/liquid/solid separation

Achieve efficient separation and clarification for diverse app...

Hygienic plate heat exchanger

Optimize temperature control for liquid processing with precision-engineered heat exchangers, ...

High-pressure hydrogenation reactor for chemical labs

Achieve precise high-temperature hydrogenation with integrated on-d...

Round motion separator for dry and wet screening

Optimize your production line with an efficient solution for precise scre...

Universal motion rectangular separator for pulp and paper

Achieve precise motion adjustments with a versatile separator ...

Industrial decanter centrifuge for solids separation

Optimize your production line with high-speed decanter centrifuges t...

Low profile flow-thru separator for wet or dry scalping

Efficiently handle high-capacity separation with a compact design...

Round vibratory separation for high capacity screening

Maximize screening efficiency with dual screen vibratory technolog...

Round vibratory separation equipment - bag dump screener system

Enhance your material handling and safety by efficiently...

Round vibratory separation for various industrial applications

Ensure accurate material separation with a robust solutio...

Vibratory finishing and deburring technology

Achieve precise surface finishing and deburring with advanced vibratory motio...

Thermal conditioning for improved meal flow and starch digestibility

Ensure optimal meal flow and starch digestibility ...

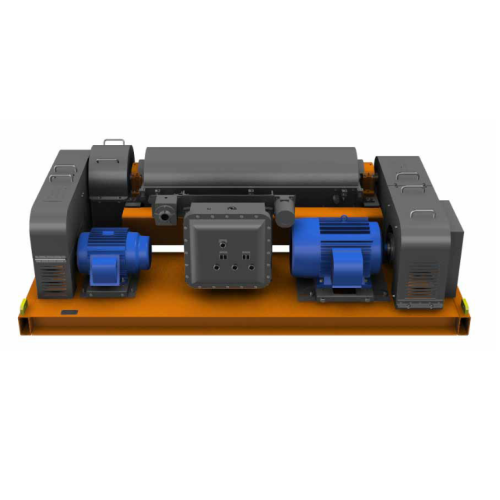

Twin shaft paddle mixer for bulk materials

Achieve precise blend consistency with a twin shaft paddle mixer designed to ha...

Continuous mixer for accurate ingredient blending

Achieve precise mixing in continuous production with optimal control ov...

Dosing screw system for precise ingredient management

Achieve unparalleled precision in formulating mixtures with our dos...

Small batch mixing rotosphere blender for food industry

Achieve precise mixing of small batch powders and granules with a...

Industrial hammermill for fine grinding applications

Elevate your milling efficiency with hammermills designed for precis...

Agricultural cleaner-separator for grain processing

Optimize your grain processing with a versatile cleaner-separator eng...

Slat conveyor dryer for industrial drying processes

Optimize your drying process with a robust slat conveyor system that ...

Stationary grain dryer with exhaust air system

Optimize your drying process with a system designed to handle diverse mater...

Grain dryer with air circulation system

Enhance efficiency and product quality with our versatile grain dryer, designed to ...

Stationary grain dryer with biturbo system

Optimize your drying processes with a system that efficiently manages air flow ...

Low-emission belt drying systems for timber industry

Optimize moisture control and energy efficiency in drying processes ...

Industrial air heater for agriculture and industry

Optimize energy efficiency and maintain high air quality in your produ...

Belt dryer for sawdust

Optimize your drying process with advanced technology engineered for precise moisture reduction in div...

Mobile belt dryer for sawdust and biomass

Efficiently reduce moisture in a variety of materials, from sawdust to cereal sn...

Side entry mixer for industrial tank applications

Ensure optimal mixing and blending of liquids and slurries with high ef...

Self-cleaning clarifiers for liquid-solid separation

Optimize your production line with high-performance self-cleaning cl...

Dewatering screens for industrial applications

Efficiently transforming wet material into dry, manageable outputs, these d...

Automated centrifugal evaporator for robotic sample handling

Streamline your laboratory workflows with this cutting-edge...

Benchtop evaporator for parallel chemistry and environmental testing

Enhance lab efficiency with a compact evaporator t...

Dewatering press for rubber, sugarcane, and biomass

Optimize your production line with a compact, energy-efficient soluti...

Seed conditioning system for edible oil processing

Optimize your oilseed processing with efficient moisture reduction and...

Edible oil processing solution

Optimize your production line with advanced pressing and dewatering technology, ensuring high...

Degumming plant for edible oil refining

Achieve optimal purity and quality in edible oils through precise degumming process...

Explosion proof weighing cells for hazardous environments

Designed for hazardous environments, these weighing cells ensu...

Agitator bead mill reactor for molecular synthesis by mechanochemistry in continuous flow

To achieve cleaner, safer,...

Production plant for biodiesel

As a biofuel producer, making biodiesel from several types of treated vegetable oils or anima...

Glycerine manufacturing plant

Glycerol or glycerin is the major by-product generated in the biodiesel production process. Bu...

Water oil separation centrifuge

Some industries, such as petrochemical, generate large volumes of oily wastewater due to the...

Industrial liquid filtration system

Systems for the filtration of liquids with suspended solid contents can be challenging ...

Industrial leaf filter for chemicals

In recent years the removal of sulphur has received increasing attention because of sa...

Advanced anaerobic digestion with external separation

Factories of dairy products, palm and coconut oil, slaughterhouses,...

Waste to energy anaerobic digestion system

The food industry produces tremendous amounts of waste at food production facil...

Anaerobic UASB wastewater treatment

If you need to remove organic compounds from your wastewater, the up-flow anaerobic slu...

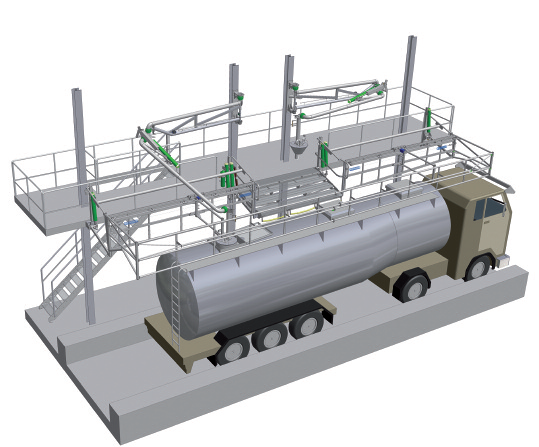

Top loading arm

Load or unload liquids from the top of the tanks safely and securely for trucks, railcars, small or big contai...

Folding stairs and safety cages

To ensure the safety of operator while working between a loading platform and road or rail t...

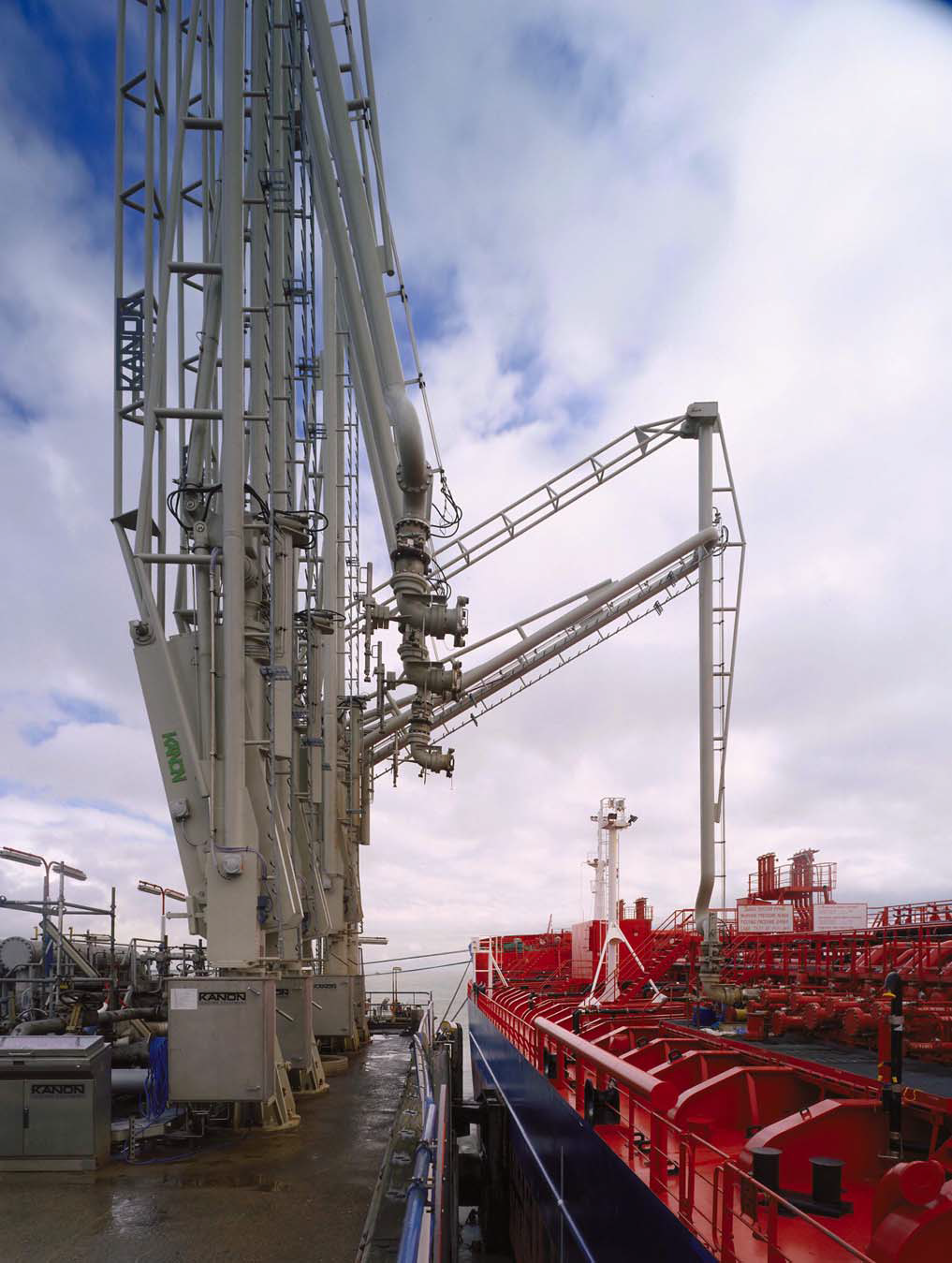

Marine loading arm

A hose or loading arm is needed when you load or unload fluids from a ship or transfer fluids between vess...

Bottom loading arm

Bottom loading/unloading arms are designed to be connected on the side or on the rear of the tanker and so...

Vertical pressure leaf filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to many in...

Horizontal pressure leaf filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to many ...

Horizontal plate scavenger filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to ma...

Filter pressure leaf

From chemical processing, to energy production, to edible oils production, product quality is often depe...