Portable process development unit for gas-liquid reactions

Optimize your gas-liquid reaction processes with a versatile, portable unit designed for precise control over reaction parameters and efficient scaling from lab to pilot production.

Facilitates Gas-Liquid Reaction Development

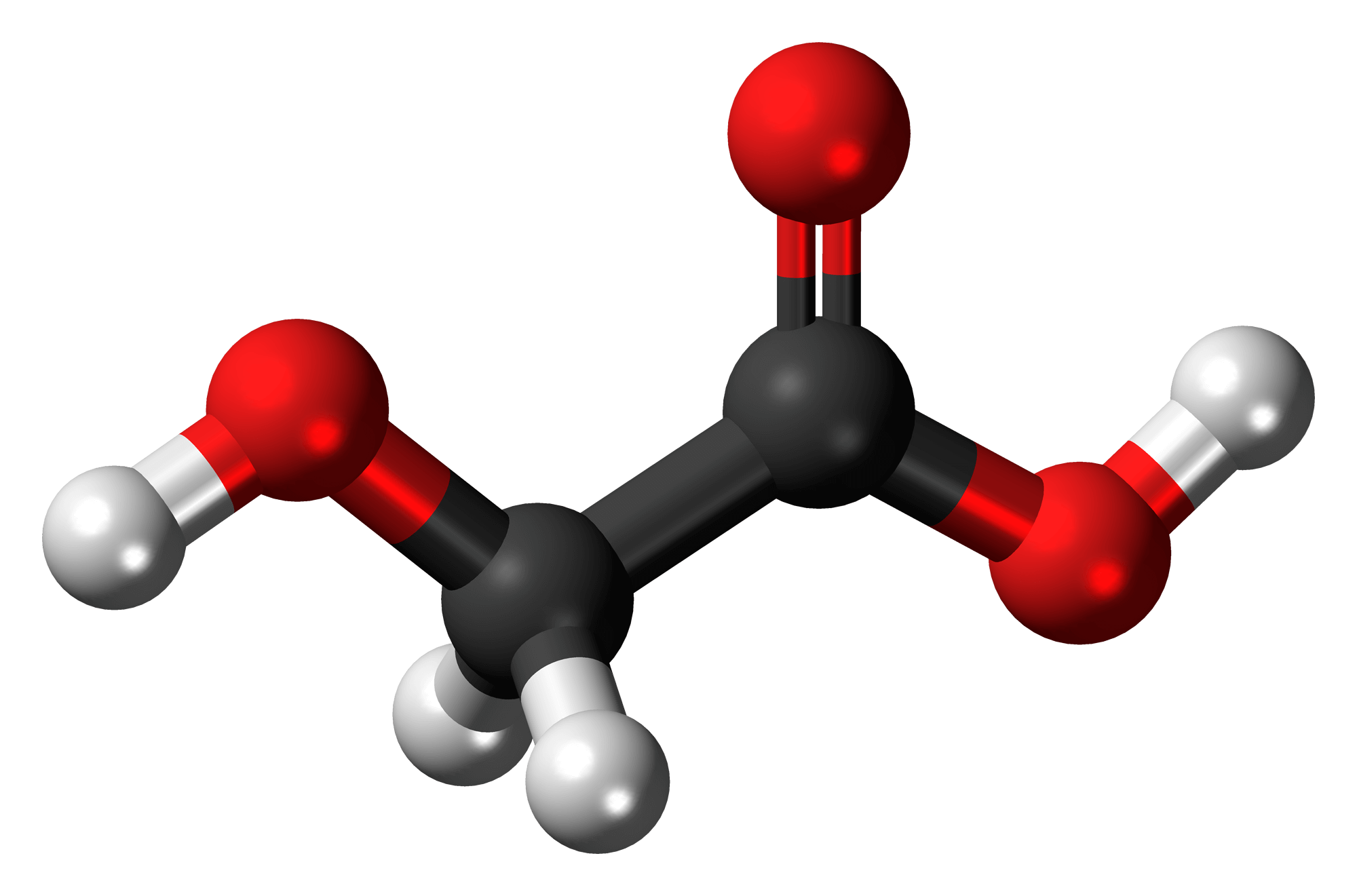

The Laboratory Plant ELA 5 from EKATO is a versatile and portable reactor unit designed for efficient gas-liquid reaction development, adaptable for use in both EX-proof areas and standard laboratory settings. It features a specialized agitation system, including the EKATO Combined Gassing System with PHASEJET and GASJET impellers, ensuring minimized mixing times and maximized mass transfer. Ideal for applications such as hydrogenation, carboxylation, and oxidation, it’s perfect for producing hydrogen peroxide, ibuprofen, and biodiesel.

Operating between 25 and 250°C and up to 81 bar, with a working volume of 3 liters and a gas feed capacity of up to 1.6 m³/h, the ELA 5 is well-suited for batch and semi-batch processes in R&D environments. The reactor’s modular design allows for integration into existing systems with adaptable baffle configurations and removable inner cooling coils. Its energy-efficient operation benefits from precision-controlled parameters, while compatibility with low-viscosity fluids ensures broad applicability.

This system is built for seamless scale-up and data analysis with EKATO’s process guarantees and monitoring capabilities, including gas feed rate, pressure, and temperature tracking. Engineers have the option for material customization to ensure chemical resistance and compliance with industry standards, supported by EKATO’s engineering and start-up services. The ELA 5 is an indispensable tool for chemical producers and biotechnology firms seeking reliable, efficient process development.

Benefits

- Enhances reaction efficiency with customized agitation systems for improved mass transfer.

- Simplifies scale-up by providing precise control over process variables.

- Increases operational flexibility with EX-proof compatibility for a variety of laboratory environments.

- Reduces energy consumption through optimized heating and cooling processes.

- Ensures process safety and compliance with adaptable, corrosion-resistant materials.

- Applications

- Chemicals, Food, Biofuels, Biotechnology, Petrochemicals, Plastics, Minerals, Pharmaceuticals

- End products

- Polyethylene, Hydrogen peroxide, Flavored syrup, Monoclonal antibodies, Ethylene glycol, Biodiesel, Ibuprofen, Calcium carbonate

- Steps before

- Process design, Planning of trials, Trial setup, Sample preparation, Equipment calibration

- Steps after

- Data analysis, Scale-up to plant scale, Process monitoring, Result validation, Cleanup and maintenance

- Input ingredients

- gas-liquid reactions, gaseous hydrogens, carboxylation agents, oxidation agents, ethoxylation agents, propoxylation agents, low viscous fluids

- Output ingredients

- Market info

- Ekato is renowned for its expertise in mixing technology and process engineering, providing innovative and high-quality solutions for industrial mixing processes across various sectors, including chemical, pharmaceutical, and cosmetics industries.

- Working volume

- 3 litres

- Gas feed rate

- 1.6 m³/h

- Temperature range

- 25 to 250°C

- Pressure range

- 0 to 81 bar (abs)

- Viscosity

- Low viscous fluids

- Process type

- Batch or semi-batch

- Phases

- Single or multiphase

- EX-proof operation

- Yes

- Working Mechanism

- Batch or semi-batch, single or multiphase

- Batch vs. continuous operation

- Batch

- Automation level

- PLC

- EX-proof operation

- Yes

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Working volume

- 3 litres

- Gas feed

- up to 1.6 m³/h

- Temperature range

- 25 to 250°C

- Pressure range

- 0 to 81 bar (abs)

- Viscosity

- low viscous fluids

- Reactor unit area compliance

- EX-proof

- Impeller systems

- EKATO PHASEJET and EKATO GASJET

- Baffle configuration

- Adaptable

- Cooling coil

- Removable inner cooling coil