Hygienic plate heat exchanger

Optimize temperature control for liquid processing with precision-engineered heat exchangers, ensuring consistent quality and efficiency in your operations.

Regulates Temperature for Efficient Process Control

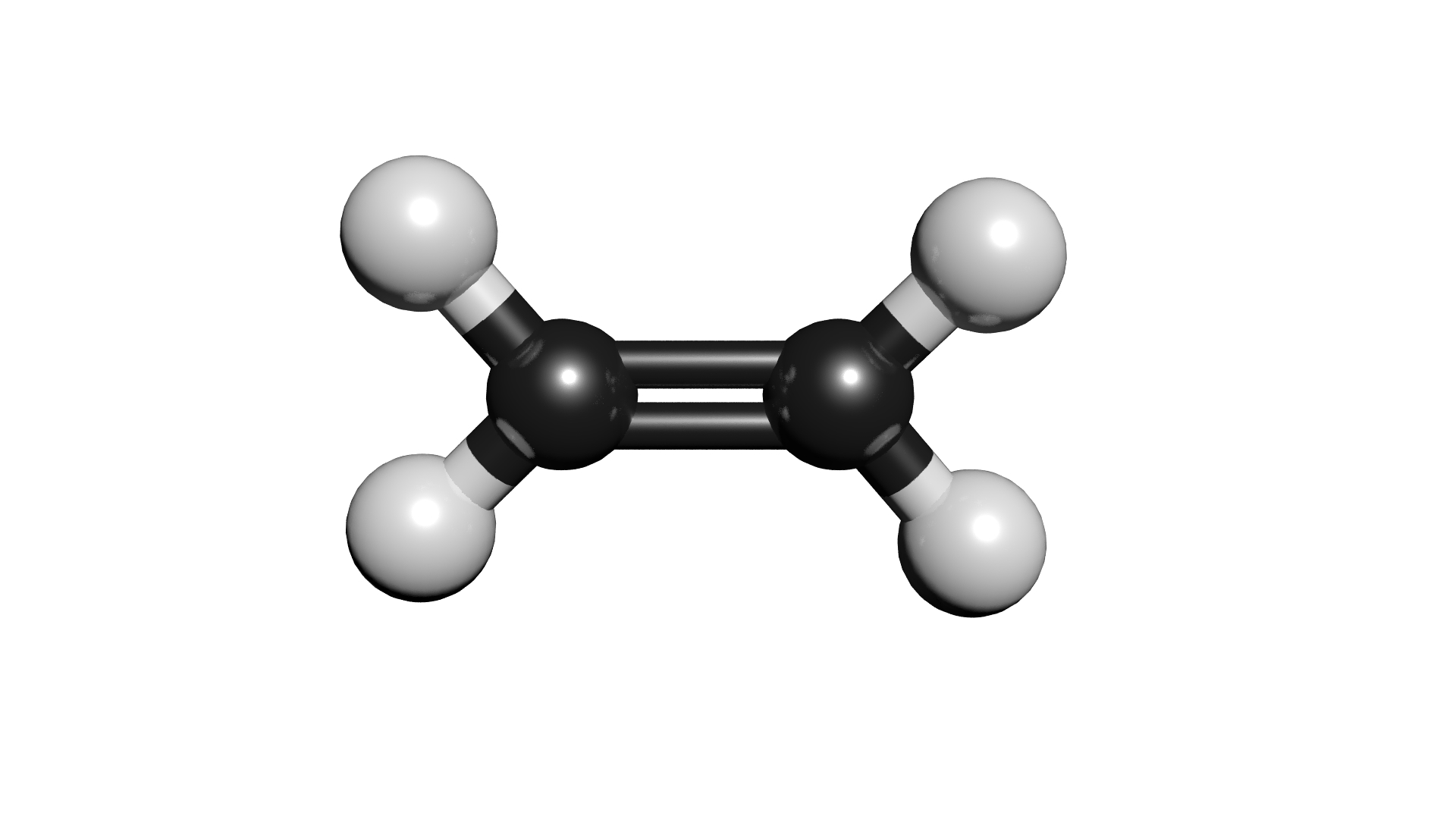

Unison’s diverse range of heat exchangers, including offerings from market leaders like API Heat Transfer and Alfa Laval, are engineered to optimize thermal management in various industries. These exchangers use innovative plate and shell designs to ensure efficient temperature regulation for liquid products such as milk, beer, and chemical solutions.

Designed to handle continuous and automated operations, they seamlessly integrate into existing production lines, supporting processes like heating, cooling, and separation. With options for hygienic and non-hygienic applications, these exchangers are suited for dairy, food and beverage, pharmaceutical, and oil and gas sectors.

Notable for their energy efficiency, these units feature variable-speed motor optimization, reducing energy consumption significantly. Built from high-grade materials like stainless steel, they offer excellent corrosion resistance, making them durable even under harsh operating conditions. Compliance with industry standards is assured, backing their application in sensitive environments.

Equipped with automatic control and monitoring systems, and offering flexible configuration possibilities, Unison’s exchangers support various customization needs, ensuring optimal performance for specific operational requirements. Their clean-in-place (CIP) systems facilitate quick maintenance, minimizing downtime and ensuring high operational uptime.

Benefits

- Enhances production efficiency with seamless integration into continuous operations.

- Cuts energy costs with variable-speed motor optimization.

- Extends equipment lifespan with corrosion-resistant materials.

- Supports regulatory compliance in sensitive environments like pharmaceuticals and food processing.

- Minimizes maintenance downtime with built-in clean-in-place systems.

- Applications

- Diesel engine cooling, Beer, Dairy, Food, Off-highway, Refrigeration, Compressors, On-highway, Air dryers, Animal health, Power generation, Alternative fuels, Air separation, Chemical, Petrochemical, Healthcare, Hvac, Pharmaceuticals, Beverages, Marine, Oil and gas, Industrial, Fluid power

- End products

- Sauces, Pet supplements, Medical devices, Lagers, Antibiotics, Cheese, Hydraulic fluids, Soups, Climate control systems, Dehydrated air, Ethylene, Nitrogen, Biodiesel, Yogurt, Engine coolants, Fruit juices, Construction equipment lubrication systems, Vaccines, Milk, Refrigerants, Marine fuel processors, Propane, Air conditioners, Stouts, Gasoline, Fertilizers, Carbonated beverages, Ethanol, Power plant condensers, Diesel, Ship hvac systems

- Steps before

- Heating, Fluid Prepping, Component Assembly

- Steps after

- Cooling, Quality Control, Packing

- Input ingredients

- milk, beer, beverage, food, chemical, petrochemical, alternative fuels, diesel, fluid, air, pharmaceutical products, water

- Output ingredients

- pasteurized milk, processed beer, processed beverage, processed food, processed chemicals, processed fuels, cooled diesel, conditioned fluid, conditioned air, processed pharmaceutical products, recycled water

- Market info

- Unison Process Solutions is known for designing and manufacturing custom-engineered process equipment for the dairy, beverage, and food industries, emphasizing innovation, quality, and tailored solutions to meet specific customer needs efficiently.

- Heat Exchanger Type

- Hygienic Plate, Non-Hygienic Plate, Wide-Gap Plate, Shell and Tube, Scrape-Surface, Brazed

- Material

- Stainless Steel, Aluminum

- Automation

- Automatic, Manual

- Testing Technology

- HEIST, Pastest+

- Design Standards

- TEMA, HEI

- Construction Type

- Bar and Plate, Tube and Header

- Gasket Type

- Mechanical-fixed, Adhesive-free

- Working Mechanism

- Plate, Shell and Tube

- Automation Level

- Manual / PLC / SCADA

- CIP/SIP

- CIP / Manual

- Changeover Time

- Quick-change designs

- Integrated Steps

- Heating / Cooling / Pasteurization

- Energy Efficiency

- High-efficiency heat transfer systems

- Batch vs. Continuous Operation

- Batch / Inline Continuous

- Non-destructive Testing

- HEIST, Pastest+

- Maintenance Frequency

- Scheduled or As-needed

- Biological compatibility

- Yes

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- Stainless steel

- Cleanability

- CIP/SIP compatible

- Shape and size

- Wide-Gap, Shell and Tube, Scrape-Surface

- Type

- Plate, Shell and Tube, Brazed

- Material

- Stainless Steel, Aluminum

- Control panel type

- PLC / SCADA integration

- HMI Type

- Touchscreen / Push-button

- Integration possibilities

- API / Custom Protocols

- Material options

- Stainless Steel / Carbon Steel

- Port configuration

- Customizable inlet/outlet positions

- Gasket material

- EPDM / NBR / Viton

- Heat exchanger design

- Custom-engineered designs

- Testing methodology

- HEIST / Pastest+