Thin film evaporator for temperature sensitive products

Need to purify temperature-sensitive compounds efficiently? Achieve high evaporation rates with minimal thermal degradation by utilizing thin film evaporation technology for precise control over residence time and temperature.

Purifies and Concentrates Temperature-Sensitive Liquids

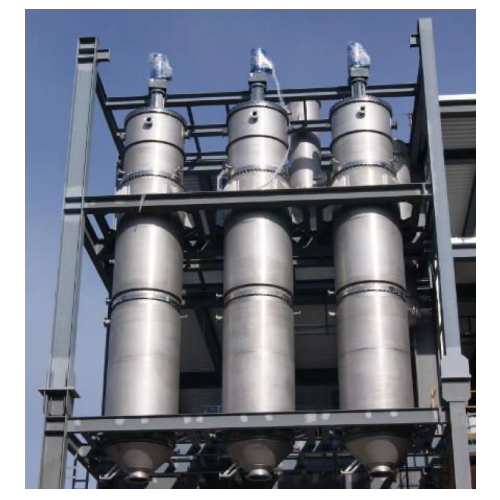

The Glass-Lined Thin Film Evaporator from De Dietrich Process Systems offers an efficient solution for the purification and concentration of temperature-sensitive substances across various industries. This equipment employs a rotating wiper system to form a thin liquid film on the evaporator’s inner wall, minimizing residence time and thermal degradation. Ideal for applications in specialty chemicals and pharmaceuticals, it effectively handles processes like methyl ester and glycerine evaporation, solvent stripping, and drying.

Capable of processing diverse materials such as acrylic polymers and active pharmaceutical ingredients, the evaporator supports pilot to continuous operations with excellent energy efficiency. Its construction from corrosion-resistant borosilicate glass and glass-lined steel ensures durability, while the transparent design facilitates direct process observation. The wiper system includes options with PTFE elements for lower-temperature processes or metallic wipers for higher-temperature requirements, accommodating a wide temperature range up to 200°C.

Fully compliant with vacuum and hygiene standards, this solution integrates seamlessly into existing lines, optimizing solvent and energy use and reducing operational costs. Easy integration with automated systems and quick clean-in-place (CIP) features ensures smooth maintenance and operational efficiency. De Dietrich also offers customizable configurations to meet specific production needs and provide comprehensive engineering support.

Benefits

- Minimizes thermal degradation and product loss with reduced residence time.

- Enhances product purity through efficient solvent separation and concentration.

- Reduces operational costs with energy-efficient heating systems.

- Supports versatile applications in multiple industries, including pharmaceuticals and green chemistry.

- Simplifies maintenance and cleaning, ensuring minimal downtime and contamination risk.

- Applications

- Methyl ester, Green chemistry, Lecithine, Pharmaceutical intermediates, Fine chemicals, Specialty chemicals, Solvents, Polymer industry, Glycerine, Plant-based ingredients, Pharmaceuticals

- End products

- Acrylic polymers, Active pharmaceutical ingredients (apis), Plant extracts, Glycerol-based personal care products, Natural essential oils, Cyanoacrylate adhesives, Biodiesel, Isocyanate monomers, Pharmaceutical excipients, Lecithin-based food emulsifiers

- Steps before

- Purification, Feeding, Heating, Vacuum Pumping

- Steps after

- Condensing, Cooling, Solvent Recovery, Concentration Adjustment

- Input ingredients

- temperature sensitive products, high boiling component, low boiling component, methyl esters, glycerine, lecithine, pharmaceutical intermediates, solvents, highly viscous products

- Output ingredients

- purified temperature sensitive products, evaporated high boiling component, evaporated low boiling component, concentrated pharmaceutical intermediates, evaporated solvents

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Evaporation temperature

- Low

- Residence time

- Short

- Evaporation rate

- High

- Material of construction

- Stainless Steel, Alloy, Borosilicate Glass, Glass-Lined Steel

- Heat exchange surface

- Borosilicate glass

- Maximum temperature with PTFE wipers

- 150°C

- Maximum temperature with metallic wipers

- 200°C

- Maximum evaporation rate

- Up to 80kg/h of organic solvents

- Operational vacuum

- Up to 1 mbar

- Wiper system types

- PTFE and metallic

- Heating medium

- Thermo-oil or steam

- Wiper thickness

- 0.1 to 0.5mm

- Working Mechanism

- Rotating wiper system

- Evaporation Temperature

- Low evaporation temperature

- Batch vs. Continuous Operation

- Inline Continuous

- Residency Time

- Short residence time

- Evaporation Rate

- High evaporation rate

- Material of Construction

- Stainless Steel, Alloy, Borosilicate Glass, Glass-Lined Steel

- Vacuum Level

- 1 mbar

- Corrosion Resistance

- Fully corrosion resistant

- Cleaning Method

- Easy cleaning

- Automation Level

- Manual / PLC

- Corrosion resistance

- Highly resistant

- Compatibility with temperature sensitive products

- Yes

- Cleanability

- Smooth surface for easy cleaning

- Compatibility with high viscosity liquids

- Yes

- Thermal stability

- Up to 200°C depending on wiper

- Borosilicate glass compatibility

- Yes

- Glass-Lined Steel compatibility

- Yes

- Resistance to organic solvents

- High

- Industries

- Specialty Chemicals, Pharmaceuticals, Fine chemicals, Green Chemistry

- ATEX certification

- Yes

- Evaporator Material

- Stainless Steel, Alloy, Borosilicate Glass, Glass-Lined Steel

- Evaporator Size

- DN40 to DN600

- Heat Exchange Surface

- 0.04m² to 3m²

- Film Thickness

- 0.1 to 0.5 mm

- Wiper System Type

- Rotating Wiper

- Material of Construction

- Stainless Steel, Alloy, Borosilicate Glass, Glass-Lined Steel

- Wiper System

- PTFE Elements, Fully Metallic

- Evaporator Size

- DN40 to DN600

- Heat Exchange Surface

- 0.04m² to 3m²

- Temperature Control

- Thermo-oil or Steam