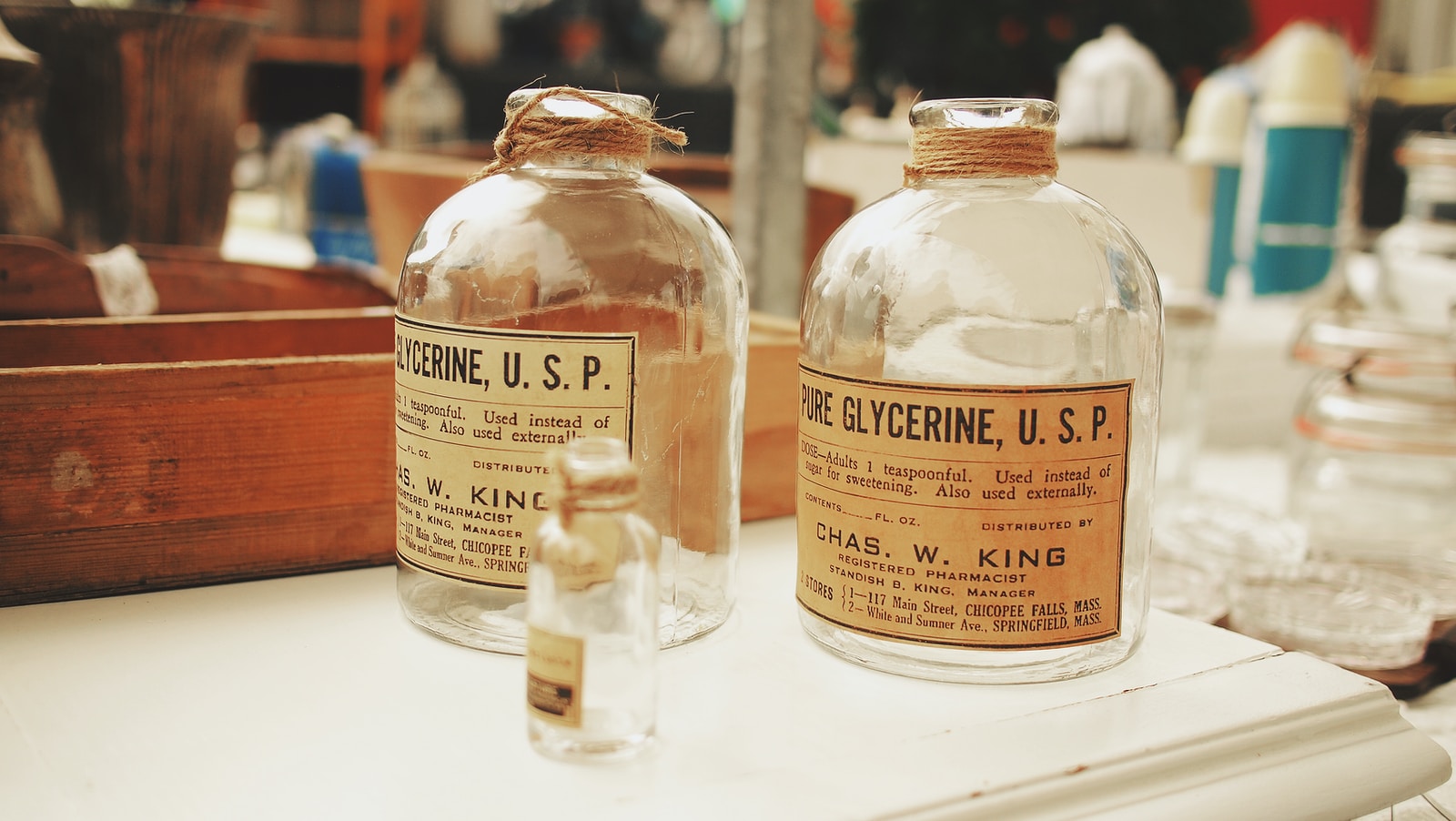

Glycerine manufacturing plant

Glycerol or glycerin is the major by-product generated in the biodiesel production process. But the disposal of glycerin or various other by-products coming from biodiesel production process pose a big challenge to industrial plants, as they can’t be disposed into the environment.

Distilling and refining glycerin while minimizing the environmental impact

Glycerin production plant designed by Andreotti Impianti produces technical and pharmaceutical glycerin from a wide range of natural feedstocks. Glycerin can be produced from different by-products coming from three industrial processes: methylesters production, fats saponification and fat splitting. The production steps change depending on the starting by-product.

For by-products such as sweet water (splitting) and spent lyes (saponification), the process path involves chemical treatment, concentration and glycerin distillation and refining. Hydrochloric acid is added in the treatment unit to reduce the solubility of fatty acids, which are then separated. Before moving on distillation process, only one filtration is carried out for sweet water, while for spent lyes, filtration is done twice, before and after the neutralization. Crude glycerin is further processed in the distillation, deodorizing and bleaching plant. The distillation system is composed of several steps: washing, rectification, condensation. In the last purification step, blenching section uses activated carbon to remove color and odor in order to obtain a pure glycerin.

It is worth mentioning that crude glycerin coming from biodiesel (methylesters) production can be sent directly to the distillation process without any further treatments, thus avoiding dilution, purification, and concentration steps.

Since one of the biggest problems caused by industrial plants today is the disposal of by-products, Andreotti Impianti has included in its plants stripping units, which help minimize the environmental impact.

Benefits

- Fully continuous multi-feedstock plant

- Ease of operation

- High environmental compatibility

- Single-column glycerin distillation

- Low installation and operational cost