Bulk solids conveying systems

Efficiently move and manage bulk materials with precision and reliability, ensuring seamless integration into your high-capacity production line.

Transports and Elevates Bulk Materials Vertically

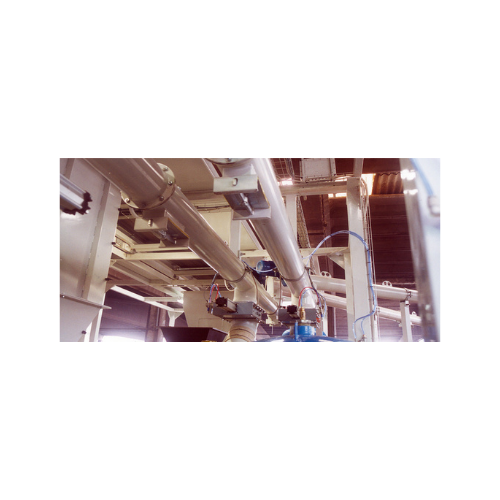

The Vertical Screw Conveyor – VE from WAMGROUP is a robust and efficient solution designed for transporting a variety of bulk materials vertically. This system employs an inclined screw mechanism to lift materials with precision, making it ideal for construction projects and production lines dealing with heavy materials, powders, or granules. With applications spanning from handling ready-mix concrete to managing dewatered sludge in wastewater treatment facilities, it is a versatile addition to any industry requiring vertical material movement. It can process significant throughput volumes efficiently, supported by high-capacity continuous operation. Engineered in durable materials, it offers high resistance to wear and corrosion, ensuring long-term reliability even in harsh environments. The VE model integrates seamlessly into existing systems, leveraging advanced PLC control for enhanced automation and remote monitoring. Its design is compliant with industry standards, offering easy maintenance with the option for customization to meet specific operational requirements.

Benefits

- Enhances operational efficiency by handling high-capacity material flow vertically.

- Integrates seamlessly into existing systems with advanced PLC control, reducing manual oversight.

- Offers durable construction, providing long-term reliability in corrosive and abrasive environments.

- Adaptable to various material types, supporting diverse industry applications.

- Minimizes maintenance time with easy access for routine cleaning and upkeep.

- Applications

- Food, Chemicals, Feed, Heavy industries, Building, Renewable energy, Biogas equipment, Animal by-products, Bulk biomass, Environmental technology, Plastics, Wastewater treatment, Construction, Sludge handling, Agriculture, Asphalt plants, Flour mills, Concrete

- End products

- Dewatered sludge cakes, Biomass pellets, Emission control systems, Biogas, Concrete blocks, Processed cheese, Polyethylene bags, Steel rods, Bread flour, Hot mix asphalt, Dyes and pigments, Clean water, Animal feed pellets, Processed pet food, Biodiesel, Bricks, Ready-mix concrete, Fertilizer granules

- Steps before

- Material Handling, Material Feeding, Material Preparation, Material Mixing

- Steps after

- Silo Storage, Material Packaging, Material Distribution, Product Quality Inspection, Load Dispatching

- Input ingredients

- bulk solids, filler dust, biomass, sludge, flour, fresh concrete, animal by-products, aggregates, minerals, biogas materials

- Output ingredients

- conveyed bulk solids, digested biomass, lifted sludge, processed flour, conveyed concrete, discharged materials

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Material Conveying Type

- Screw, Bucket, Chain

- Screw Conveyor Size

- Varies per custom design

- Material Compatibility

- Stainless Steel / Heavy-Duty

- Temperature Handling

- Can handle high temperatures

- Capacity

- Varies per application

- Vertical Conveying Capacity

- High Capacity

- Automation Level

- Manual, PLC-controlled

- Load Capacity

- Varies based on configuration

- Screw Conveyor Configuration

- Vertical, Trough, Tubular

- Pressure Resistance

- High pressure capable

- Installation Type

- Robust and versatile

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact or customized to space requirements

- Discharge method

- Screw or trough

- Compact footprint

- Available for smaller spaces

- Control panel type

- PLC / Touchscreen

- Integration possibilities

- SCADA / DCS

- Material compatibility

- Stainless Steel / Carbon Steel

- Finish quality

- Food-grade / Industrial-grade

- Size customization

- Custom lengths and diameters