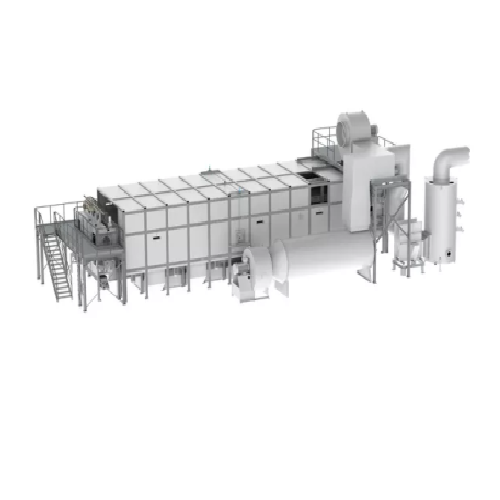

Slat conveyor dryer for industrial drying processes

Optimize your drying process with a robust slat conveyor system that accommodates high-speed, continuous operations, ensuring precise moisture control for various materials, from grains to wood chips, in large-scale production environments.

Dries and Granulates Diverse Industrial Materials

The Slat Conveyor Dryer Type PBT from STELA Laxhuber is engineered to deliver efficient drying and granulating solutions across multiple industries, including agriculture, timber, and renewable fuels. Its robust design accommodates process temperatures up to 220°C, providing reliability in high-demand environments. The dryer integrates into multi-conveyor systems, optimizing space while maintaining continuous, high-speed operations. It offers belt widths of 2.5 m or 4 m, catering to different production scales. The system minimizes dust via its effective granulators and ensures even material distribution for consistent drying results. With automation support for streamlined integration, the Slat Conveyor Dryer enhances energy efficiency through precise motor control, reducing operational costs. Stainless steel construction ensures durability, with options available for specific corrosive environments. Configuration and engineering support allow for tailored solutions to meet unique processing needs, making it a versatile addition to any production line focused on solid, granule, or powder products.

Benefits

- Ensures uniform drying and granulation, improving end-product quality and reducing waste.

- Saves floor space through compact, multi-conveyor system integration.

- Decreases operational costs with energy-efficient motor controls.

- Offers flexibility with customizable configurations to suit diverse production needs.

- Minimizes maintenance with robust, durable construction for extended equipment lifespan.

- Applications

- Pet food, Pellets, Recycling materials, Renewable fuels, Agricultural products, Foodstuffs, Pulp and paper, Timber industry, Urban sewage sludge, Cement

- End products

- Grains, Wood chips, Dried pulp fibers, Alternative cement fuels, Wood pellets, Extrudates for snacks, Dried vegetables, Treated sewage sludge, Biodiesel, Pet food kibble, Composted materials

- Steps before

- Granulation, Material input preparation

- Steps after

- Product cooling, Packaging, Storage

- Input ingredients

- fibres, chips, OSB strands, cereals, vegetables, extrudates, pet food, livestock feed, sewage sludge, sawdust, wood chips, Solid Recovered Fuel (SRF)

- Output ingredients

- dried fibres, dried chips, dried OSB strands, dried cereals, vitamin-preserved dried vegetables, dried extrudates, dried pet food, dried livestock feed, dried sewage sludge, dried sawdust, dried wood chips, dried SRF

- Market info

- Stela Laxhuber is known for their expertise in manufacturing custom-engineered drying systems, particularly belt dryers for biomass, sludge, and food industries, with a reputation for innovation, quality, and energy efficiency in the market.

- Process Temperature

- Up to 220°C

- Belt Width

- 2.5 m or 4 m

- Multi-conveyor System Capability

- Space-saving

- Working Mechanism

- Slat Conveyor Dryer

- Process Temperatures

- up to 220°C

- Integration Level

- Space-saving multi-conveyor systems

- Automation Level

- Manual / PLC / SCADA

- Batch vs. Continuous Operation

- Continuous

- Energy Efficiency

- Low kWh/kg moisture

- Cleaning Method

- Manual

- Automation

- PLC-Controlled

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Conveyor width

- 2.5 m or 4 m

- Maximum process temperature

- 220°C

- Space-saving system

- Multi-conveyor systems

- Design

- Robust and durable

- Belt Width

- 2.5 m / 4 m

- Process Temperatures

- Up to 220°C

- Multi-Conveyor Systems

- Space-saving Implementation

- Dryer Design

- Robust, Durable

- Integration Features

- Low Emission Belt Systems