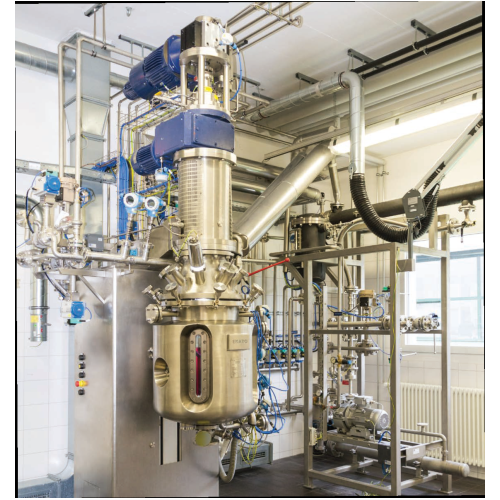

Pilot plant for highly viscous applications

Perfect for R&D, this pilot plant efficiently handles complex mixing and degassing for highly viscous batches, optimizing your process development with precision control.

Processes Highly Viscous Materials in Pilot Batches

The Pilot Plant ELA 50 from EKATO is designed specifically for processing highly viscous materials under controlled conditions. Featuring a coaxial agitator system with both central and close-to-the-wall impellers, it withstands viscosities up to 1,000 Pa·s. This plant is EX-proof (T3, IIB), making it suitable for flammable liquids and a range of applications, including pharmaceuticals, biopharmaceuticals, and specialty chemicals. It excels in processes like mixing, degassing, and solvent evaporation, offering batch and semi-batch operations up to 60 liters. Integrated with a vacuum station for efficient solvent recovery, it ensures optimal energy use, enhanced mass and heat transfer, and reduced mixing times. The ELA 50 supports GMP compliance with modifications available, such as steam injection, to meet diverse operational needs. Maintenance is streamlined with support from EKATO’s mixing specialists, providing trials, scale-up expertise, and analytical monitoring.

Benefits

- Enhances production efficiency with superior mixing and heat transfer capabilities in viscous applications.

- Reduces energy consumption through optimized impeller systems and vacuum integration.

- Adapts to flammable and hazardous environments with its EX-proof design, ensuring safety and compliance.

- Streamlines process development with flexible batch and semi-batch operations.

- Lowers contamination risks with available modifications and expert support in meeting GMP standards.

- Applications

- Food, Biofuels, Fine chemicals, Cosmetics, Biopharmaceuticals, Minerals processing, Petrochemicals, Plastics, Pharmaceuticals

- End products

- Propylene, Polyethylene, Sauces, Specialty chemicals, Polypropylene, Active pharmaceutical ingredients (apis), Monoclonal antibodies, Mineral concentrates, Ethylene, Dressings, Biodiesel, Lipsticks

- Steps before

- Purification, Drying, Emulsification, Grinding, Crystallization

- Steps after

- Sterilization, Packing, Coating

- Input ingredients

- highly viscous materials, flammable liquids, batch materials, semi-batch materials, solids, suspensions, degassing agents, solvents

- Output ingredients

- processed materials, suspensions, degassed products, dispersed products, evaporated solvents

- Market info

- Ekato is renowned for its expertise in mixing technology and process engineering, providing innovative and high-quality solutions for industrial mixing processes across various sectors, including chemical, pharmaceutical, and cosmetics industries.

- Working volume

- 60 litres

- Temperature range

- 20 to 200°C

- Pressure range

- 40 mbar (abs) to 4 bar (abs)

- Viscosity capability

- up to 1, 000 Pa s

- Batch operation

- Batch or semi-batch

- Impeller systems

- Central and close-to-the-wall impellers

- Coaxial agitator

- Coaxial installation

- EX-proof certification

- EX-proof (T3, IIB)

- Vacuum capability

- Degassing and solvent recovery

- Heat transfer

- Optimization for increased heat transfer

- Batch vs. continuous operation

- Batch / Semi-batch / Multiphase

- Automation level

- Manual / PLC

- Air incorporation control

- Degassing vacuum

- Energy efficiency

- N/A

- Cleaning method

- CIP Compatible

- Changeover time

- N/A

- CIP/SIP

- CIP 121°C / SIP 135°C

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- EX-proof

- T3, IIB

- Tank shape and size

- 50 liters

- Reactor type

- Coaxial agitator system

- Operating temperature range

- 20 to 200°C

- Pressure range

- 40 mbar (abs) to 4 bar (abs)

- Viscosity handling capacity

- up to 1, 000 Pa s

- EX-proof certification

- T3, IIB

- Control panel type

- PLC/HMI

- Agitator configuration

- Coaxial with independent drive systems

- Impeller system

- Central and close-to-the-wall impeller

- Vacuum system

- With condenser

- EX-proof modification

- T3, IIB