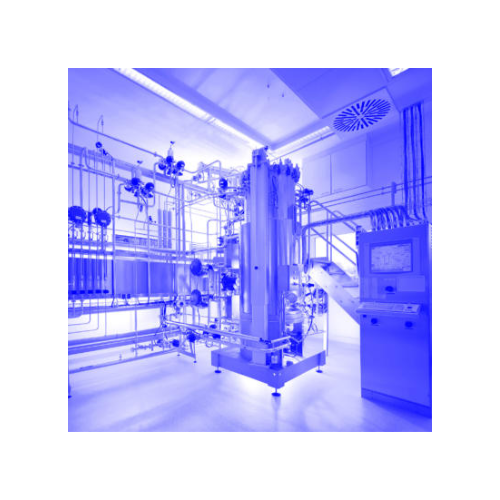

Lab-scale fermentors for microbial cultivation

Optimize microbial cultivation with lab-scale fermentors designed for precise control over fermentation processes, addressing challenges such as oxygen supply, temperature regulation, and automated dosing, ensuring high-quality yield consistency even in challenging environments.

Cultivates Microorganisms and Optimizes Fermentation Conditions

The stainless steel fermentor from Bioengineering is engineered to streamline microbial cultivation for the biopharmaceutical and nutraceutical industries. This equipment leverages advanced aeration strategies and precise control over oxygen supply, dosage, and temperature, ensuring optimal fermentation conditions for producing insulin, vaccines, and monoclonal antibodies. With capacities ranging from 30 to 50,000 liters, the fermentor accommodates both pilot and full-scale production. Designed for seamless integration into existing production lines, it features a PLC-controlled system for automated operations and offers compatibility with various control software, including BioSCADA, for intuitive management. Compliant with GMP standards, the fermentor includes integrated CIP systems for efficient cleaning and maintenance. Additionally, Bioengineering provides customization options to suit specific production needs, backed by over 50 years of industry expertise.

Benefits

- Enhances production efficiency with precise control over fermentation parameters.

- Reduces operational costs through automation and seamless integration with existing control systems.

- Supports a wide range of applications, from pharmaceuticals to nutraceuticals, enabling diverse product output.

- Ensures compliance with industry standards, promoting safe and high-quality manufacturing.

- Minimizes contamination risk with integrated CIP systems for effective cleaning.

- Applications

- Food, Homeopathy, Metal powders, Liquid formulations, Fine chemicals, Snacks, Nutraceuticals, Beverage, Performance materials, Alternative medicine, Cosmetics, Biopharmaceuticals, Pharmaceutical products, Biofuel

- End products

- Metal alloy powders, Protein powders, Vaccines, Flavored beverages, Analgesic tablets, Nutritional snack bars, Insulin, Liquid cough syrups, Monoclonal antibodies, Vitamin supplements, Homeopathic tinctures, Biodiesel, Ceramic coatings, Essential oils

- Steps before

- Microbial Cultivation, Process Requirement Determination, Stainless Steel Fabrication, Design and Engineering, Oxygen Supply Optimization, Stirrer Dimensioning, Heating and Cooling Circuit Setup

- Steps after

- Sterilization, Aeration Strategy Development, Dosage Vessel Integration, Continuous Fermentation, GMP Production Compliance, High Cell Density Management

- Input ingredients

- bacteria, archaea, yeast, extremophiles, oxygen, corrective agents, acids, bases, anti-foams, culture media

- Output ingredients

- microbial cultivation, fermented cultures, microorganism, high cell density cultures

- Market info

- Bioengineering is known for its expertise in designing and manufacturing customized bioreactors and fermenters, serving the biotechnology and pharmaceutical industries. They are reputed for high-quality, engineered-to-order solutions and innovative process technologies.

- Fermentor Capacity

- 30 to 50, 000 liters

- Vessel Geometry Ratio (h

- d)

- Oxygen Supply/Aeration

- Customizable, High kLa

- Heating/Cooling Circuit

- Fast-Response

- Automation

- BioSCADA Software

- Stirrer Dimensioning

- Customizable

- Material

- Stainless Steel cGMP

- Microorganisms Supported

- Bacteria, Archaea, Yeast, Extremophiles

- CIP/SIP Capability

- Integrated

- Temperature Control

- Rapid Heating/Cooling

- Dosage Vessels

- For acids, bases, anti-foams

- Automation level

- SCADA / PLC

- Batch vs. continuous operation

- Batch / Continuous

- CIP/SIP capability

- CIP / SIP

- Short heating and cooling periods

- Priority for culture media

- Dosage integration

- Acids, bases, anti-foams

- Customized fermentation system

- Based on microorganism requirements

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Microbial cultivation type

- Bacteria, archaea, yeast, extremophiles

- Tank shape

- Cylindrical

- Tank size

- 30 to 50, 000 liters

- Typical vessel geometry

- h

- Machine footprint

- N/A

- Control panel type

- Intuitive HMI

- Control panel type

- Intuitive HMI

- Integration possibilities

- BioSCADA software

- Software architecture

- Optimized for Bioreactor environment

- Vessel capacity range

- 30 to 50, 000 liters

- Vessel geometry

- h

- Heating and cooling circuit options

- Short heating and cooling periods

- Aeration strategies

- Customizable with high kLa value

- Dosage system

- Fully integrated dosage vessels

- Material

- Stainless steel (cGMP)