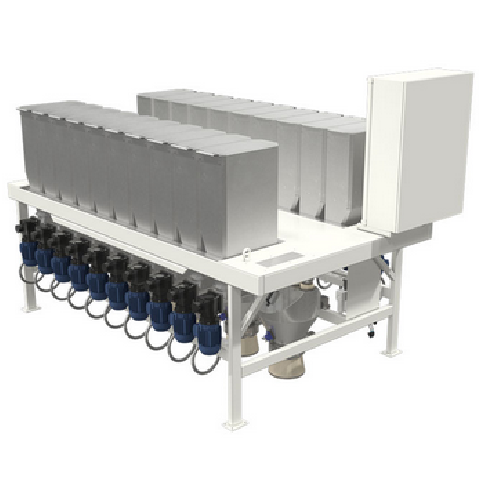

Accurate weighing system for micro ingredients

Ensure precise micro-ingredient dosing for batch operations with this versatile weighing system, designed to optimize accuracy and speed while preventing cross-contamination in high-stakes production environments.

Precisely Weighs and Batches Micro Ingredients

The MicroScale Weighing System from CPM is engineered to precisely measure and batch micro ingredients for various industrial applications. This versatile system is available in three configurations: Rollover Hoppers, Funnel Hoppers, and Conical Hoppers, each designed to optimize accuracy, speed, and segregation in your processing line. With applications in animal feed, pet food, aquaculture, food industry, and biomass, the MicroScale efficiently handles powders and granules, ensuring consistent product quality. Capable of weighing up to 24 ingredients with precise resolution, this system is ideal for operations needing high-speed and batch processing. Integration friendly, it’s compatible with PLC systems for seamless automation, allowing for enhanced control and remote monitoring for increased operational efficiency. Optional features such as bin level sensors and dust collection hoods further support operational precision and cleanliness. Whether you’re producing compound animal feed, biodiesel, or brewer’s hops pellets, CPM’s MicroScale ensures your weighing process is efficient and tailored to your needs.

Benefits

- Enhances accuracy in micro ingredient batching, improving product consistency.

- Supports diverse industrial applications, offering flexibility across multiple production lines.

- Minimizes cross-contamination with individual hopper design for ingredient segregation.

- Integrates seamlessly with automation systems, streamlining operational efficiency.

- Reduces production time with high-speed weighing capabilities, optimizing throughput.

- Applications

- Aquaculture, Animal feed, Ethanol, Pet food, Hemp, Food industry, Oilseed processing, Hops, Rendering, Biomass

- End products

- Protein-enriched bars, Brewer's hops pellets, Dog kibble, Cereals, Ethanol fuel, Cat biscuits, Fish feed pellets, Plant-based protein supplements, Biodiesel, Compound animal feed, Hemp seed oil, Canola oil

- Steps before

- Grinding, Mixing, Processing, Ingredient Preparation

- Steps after

- Batching, Mixing, Pelleting, Packaging

- Input ingredients

- micro ingredients, batching system ingredients

- Output ingredients

- accurately weighed ingredients, segregated ingredients

- Market info

- CPM is known for manufacturing high-quality process equipment and technology solutions for the industrial and agricultural sectors, specializing in particle size reduction, conditioning, and pelleting solutions with a strong reputation for reliability and innovation.

- Accuracy

- .01 to .1 lbs. resolution

- Number of ingredients

- 4 to 24

- Average draw weight

- 1 to 20 lbs.

- Bin capacity

- 6, 8, 10 cu. ft.

- Hopper capacity

- 3 to 18 cu. ft.

- Speed control

- Direct, remote I/O or integrated

- Number of ingredients

- 4 to 24

- Average draw weight

- 1 to 20 lbs.

- Bin capacity

- 6, 8, 10 cu. ft.

- Hopper capacity

- 3 to 18 cu. ft.

- Scale display resolution

- .01 to .1 lbs.

- Batch vs. continuous operation

- Batch

- Speed control

- Direct, remote I/O or integrated

- Density/particle size

- Applicable for micro ingredients

- Cross-contamination prevention

- Ingredient segregation

- Hopper Type

- Rollover, Funnel, Conical

- Discharge Method

- Hopper discharge

- Shield Enclosure

- Reduces air movement

- Hopper configuration

- Rollover / Funnel / Conical

- Frame type

- Freestanding / Drop-through

- Bin capacity

- 6, 8, 10 cu. ft.

- Hopper capacity

- 3 to 18 cu. ft.

- Lid features

- 6-inch flange / Lid lock systems

- Dust collection

- Dust collection hoods

- Speed control

- Direct / Remote I/O / Integrated