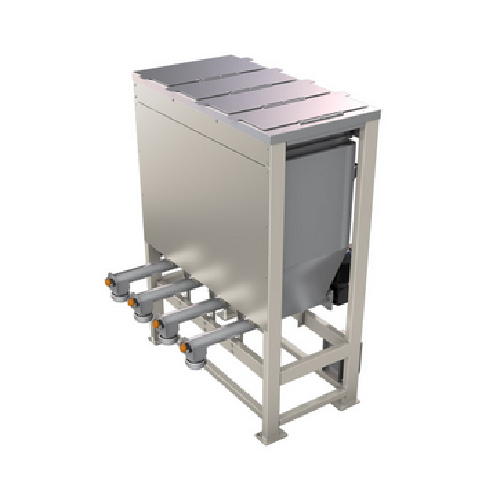

Loss-in-weight scale for micro ingredient batching

Enhance precision in your production line with advanced micro ingredient batching, ensuring consistent quality and optimal inventory management for high-speed operations.

Accurately Weighs and Monitors Batching Ingredients

The Loss-in-Weight Scale from CPM accurately measures micro ingredients for batching systems, ensuring precise and efficient production. Designed for applications including animal feed, oilseed processing, and pet food, it supports batching operations with continuous inventory monitoring and high-speed weighing. Ideal for daily capacities under 500 pounds, it features a variable frequency drive (VFD) for enhanced control. The system accommodates 4 to 100 ingredients, with draw weights from 1 to 10 pounds and bin capacities of 6 cubic feet. Options like bin level sensors and integrated speed control optimize performance. The scale integrates smoothly into production lines, offering precise ingredient management and operational efficiency.

Benefits

- Enhances batching accuracy and consistency, improving product quality.

- Streamlines inventory management with accurate, real-time monitoring.

- Reduces operational costs through high-speed, efficient weighing.

- Customizable configurations meet diverse production needs.

- Integrates seamlessly into existing production lines for minimal disruption.

- Applications

- Aquaculture, Animal feed, Ethanol, Pet food, Hemp, Food industry, Oilseed processing, Rendering, Biomass

- End products

- Tallow, Livestock feed pellets, Dog kibble, Wood pellets, Fish pellets, Hemp oil, Biodiesel, Soybean meal, Protein bars

- Steps before

- Grinding, Mixing, Ingredient Preparation

- Steps after

- Batching, Packaging, Inventory Monitoring

- Input ingredients

- micro ingredients, batching materials

- Output ingredients

- batched materials, measured micro ingredients

- Market info

- CPM is known for manufacturing high-quality process equipment and technology solutions for the industrial and agricultural sectors, specializing in particle size reduction, conditioning, and pelleting solutions with a strong reputation for reliability and innovation.

- Number of ingredients

- 4 to 100

- Average draw weight

- 1 to 10 pounds

- Bin capacity

- 6 cu/ft

- Scale display resolution

- 0.05 to 0.1 pounds

- Cycle draw

- 1 to 20 pounds

- Daily usage

- Under 500 pounds

- Working mechanism

- Loss-in-weight

- Integrated steps

- Continuous inventory monitoring

- Batch vs. continuous operation

- Batch

- Cycle draw range

- 1 to 20 pounds

- Daily usage

- Under 500 pounds

- Scale display resolution

- 0.05 to 0.1 pounds

- Number of ingredients

- 4 to 100

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Batching system use

- Micro ingredients

- Inventory monitoring

- Continuous

- High-speed weighing

- With multiple VFD option

- Bin capacity

- 6 cu/ft

- Average draw weight

- 1 to 10 pounds

- Scale display resolution

- .05 to .1 pounds (based on environment)

- Number of ingredients

- 4 to 100

- Control panel type

- Direct, Remote I/O, Integrated

- Refill bin lids

- 6-inch flange

- Bin level sensors

- Optional

- Bin vibrators

- Optional

- Lid lock systems

- Available

- Speed control

- Direct, Remote I/O, Integrated