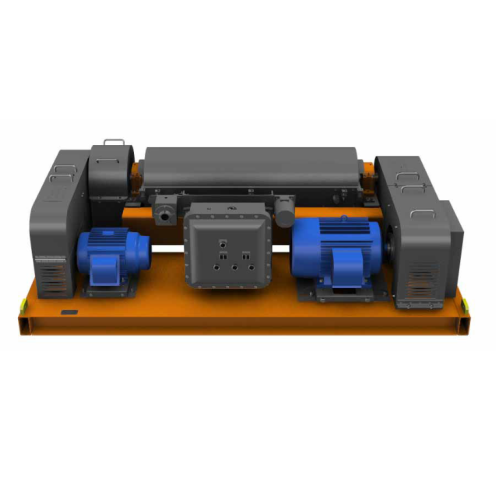

Industrial decanter centrifuge for solids separation

Optimize your production line with high-speed decanter centrifuges that ensure efficient solids-liquid separation and adaptable dewatering processes, enhancing material recovery and reducing disposal costs in demanding environments.

Processes and Separates Slurries Continuously

The SWECO CD600 Centrifuge is a high-speed industrial decanter designed for effective solid-liquid separation across various industries, including agriculture, biofuel, and pharmaceuticals. It operates using a multi-stage decanting system, allowing for continuous and efficient processing of slurries. With the ability to handle large volumes, it is ideal for high-capacity operations. The CD600 features stainless steel wetted parts and tungsten carbide hard facing for enhanced corrosion resistance, ensuring longevity in harsh environments. Integrated with variable frequency drives, it optimizes energy consumption, reducing start-up amperage and eliminating mechanical adjustments. This centrifuge is PLC-controlled, offering seamless integration into existing production lines and the capability for remote monitoring. Additionally, it supports customization to meet specific processing requirements, backed by engineering support for tailored solutions.

Benefits

- Increases production efficiency with continuous solid-liquid separation.

- Enhances durability and longevity in corrosive environments with robust construction.

- Lowers operational costs through energy-efficient variable frequency drives.

- Integrates seamlessly into diverse production lines for versatile applications.

- Customizable options ensure optimal performance tailored to specific industrial needs.

- Applications

- Food, Mineral, Maritime, Beverage, Laundry, Chemical, Ceramic, Wastewater, Plastic, Pulp, Paper, Mining, Shot peening, Agriculture, Powder coating, Biofuel, Recycling, Pharmaceutical

- End products

- Fish oil, Minerals, Pharmaceutical compounds, Crude oil, Recycled plastics, Beer, Linen cleanliness, Wine, Ceramic tiles, Starch, Biodiesel, Recycled paper, Recycled metals, Plastic pellets, Fruit juices, Powder paint, Vegetable oil, Sugar, Liquid detergents, Vegetable juices, Fertilizers, Ethanol, Polished metal parts, Industrial wastewater effluent, Crop chemicals, Ore concentrates

- Steps before

- Grinding, Drying

- Steps after

- Recycling, Packing

- Input ingredients

- solids, liquid, process streams

- Output ingredients

- recovered materials, separated solids, liquid waste

- Market info

- Sweco is known for engineering consulting services, providing expertise in sustainable infrastructure, architecture, and engineering projects, with a strong reputation for delivering comprehensive solutions in urban planning, environmental services, and industrial ETO equipment design and consultancy.

- Speed

- High RPM speeds

- Capacity

- High volume dewatering applications

- Material

- Corrosion-resistant materials

- G-force

- Extremely high G-forces

- Feed Tube

- Three-port

- Back Drive Speed

- Adjustable from -18 to +85 RPMs

- Scroll Points

- Tungsten carbide

- Bowl Drive

- Infinite speed adjustability

- Backdrive

- Variable frequency drives

- Start-up

- Low amperage

- Sheave Changes

- Eliminated

- Construction Material

- Stainless steel wetted parts

- Hard Facing

- Tungsten carbide

- High-speed operation

- High RPM speeds

- Variable frequency drives

- Infinite speed adjustability

- Back drive speed adjustability

- -18 to +85 RPMs

- Environment adaptability

- Environmentally sensitive areas

- Long operation periods without interruption

- Precision-balanced for smooth operation

- Main bowl drive adjustability

- Variable frequency drives

- Corrosion resistance

- Stainless steel, tungsten carbide

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact/Rugged

- Material

- Corrosion-resistant materials

- Feed type

- Three-port feed tube

- Size

- Varied for different models

- Speed adjustability

- Infinite adjustments

- Materials for wetted parts

- Stainless steel

- Construction materials

- Stainless steel wetted parts, tungsten carbide hard facing

- Feed oil type

- Three-port feed tube

- Scroll points

- Tungsten carbide scroll points