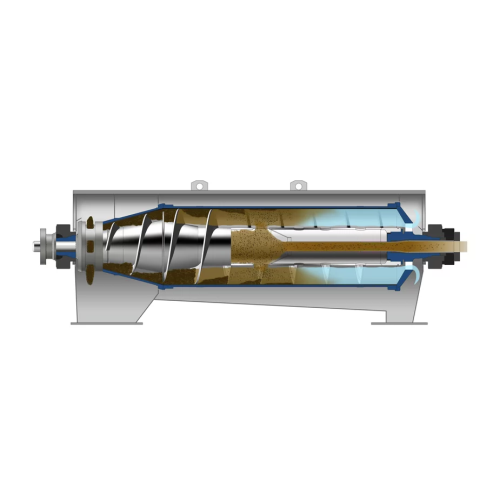

Decanter centrifuge for wastewater treatment

Effectively manage waste streams and enhance resource recovery with this high-performance decanter centrifuge, designed to optimize solid-liquid separation and reduce operational costs in continuous processing environments.

Dewaters and Clarifies Wastewater Efficiently

The Flottweg C-series Decanter Centrifuge offers a robust solution for wastewater and sludge treatment, designed with Flottweg’s renowned engineering. Its unique dual-cone design enhances separation efficiency by compacting solids against a baffle plate, significantly optimizing the dewatering of municipal sewage and industrial waste. This centrifuge operates continuously, using the Simp Drive® system to independently control bowl and differential speeds for consistent throughput, even with variable feed conditions. The optionally integrated Recuvane® system allows for energy recovery, further reducing operational costs by up to 30%. Constructed with high-quality stainless steel and offering a comprehensive wear protection package, it ensures long-term durability and minimal maintenance. Ideal for applications in water treatment, bioplastics, and biofuel production, this equipment can process significant volumes with customizable rotor speeds and configurations, ensuring compliance with industry standards and seamless integration into existing systems.

Benefits

- Increases dewatering efficiency, reducing sludge volume and disposal costs by 8%.

- Recovers up to 30% of energy through the Recuvane® system, lowering operational expenses.

- Durable stainless steel construction prolongs service life, minimizing maintenance requirements.

- Adapts to varying feed conditions for optimal dry solids content, ensuring consistent output.

- Integrates seamlessly with existing systems, enhancing overall plant efficiency and safety.

- Applications

- Sewage sludge, Industrial waste treatment, Slaughterhouse and rendering industry, Wastewater treatment, Edible fats and oils, Chemicals, Mineral oils, Fermentation broths, Protein oil crops, Protein grasses, Bioplastics, Protein starch crops, Plastics recycling, Pharmaceuticals, Beverages, Biofuels, Ethanol, Drinking water treatment, Food residue, Municipal water treatment, Algae, Leaves

- End products

- Animal feed additives, Chemical reagents, Pharmaceutical compounds, Biodegradable plastics, Protein concentrates from corn, Fermented amino acids, Purified drinking water, Ethanol fuel, Treated sewage sludge, Refined mineral oil, Biodiesel, Treated municipal wastewater, Olive oil, Gelatin, Clear fruit juice, Alfalfa protein extract, Recycled plastic pellets, Algal extracts, Soy oil, Treated industrial waste

- Steps before

- Sludge Collection, Pre-Treatment, Flocculant Addition

- Steps after

- Sludge Disposal, Water Reclamation, Effluent Treatment

- Input ingredients

- sewage sludge, waste water, municipal waste water, drinking water, separation medium, flocculant

- Output ingredients

- dry solids, separated water, centrate

- Market info

- Flottweg is renowned for manufacturing high-performance centrifuges, separators, and belt presses, specializing in solid-liquid separation technology for various industries. They are known for innovation, quality, and customized solutions meeting specific customer needs.

- Size

- Various (C2E to C8E dimensions)

- Weight

- Various (1400 kg to 13070 kg)

- Automation

- Fully automatic

- Energy consumption reduction

- 10% to 30% with Recuvane® system

- Dry solids content

- 23% to 25% example improvement

- Power density

- High within a small footprint

- Drive system

- Flottweg Simp Drive®

- Maintenance access

- Easy access for rotor and scroll

- Material

- High-quality stainless steel

- Pond depth

- Optimally set for high dehumidification

- Separation values

- Several percentage points higher

- Energy efficiency

- Reduced energy consumption

- Automation level

- Full automation / 24-hour operation

- Batch vs. continuous operation

- Continuous operation

- Cleaning method

- Easy maintenance / On-site serviceability

- System integration

- Compatible with overall plant control system

- Dry solids control

- Consistent high dry solids value

- Energy recovery

- Recuvane® system for energy recovery

- Maintenance accessibility

- Quick assembly and disassembly

- Abrasion resistance

- High due to wear protection package

- Corrosive resistance (e.g. acids)

- High due to stainless steel components

- Cleanability

- Designed for easy cleaning and maintenance

- Density/particle size

- Varies based on application

- Discharge method

- Via decanter scroll to conical bowl end

- Scroll design

- Double cone with baffle plate

- Material

- High-quality stainless steel

- Bowl design

- Increased sedimentation volume, longer clarification section

- Control panel type

- PLC-controlled / HMI

- Integration possibilities

- SCADA / Enterprise 4.0 systems

- Scroll design customization

- Various scroll geometries available

- Bowl and scroll drive

- Customizable differential speed

- Flocculant dosing

- Manual / Automated

- Sealing System

- Customizable for odor control