Industrial liquid filtration system

Systems for the filtration of liquids with suspended solid contents can be challenging with corrosion issues and cold spots. They require high maintenance and operational costs. If you are a small-scale company in industries that require sulphur processing, amine treating or need to continuously filter out fine solids, you need a flexible solution and cost-efficient solution which is easy to maintain.

Low maintenance and flexible filtration system

Sulphurnet’s Horizontal plate filter is configured for both continuous and batch wise filtration without leaving any solid residue. It is equipped with a scavenger plate which refilters the residue left in the tank at the end of a batch. It also allows complete product recovery by washing or drying the cake.

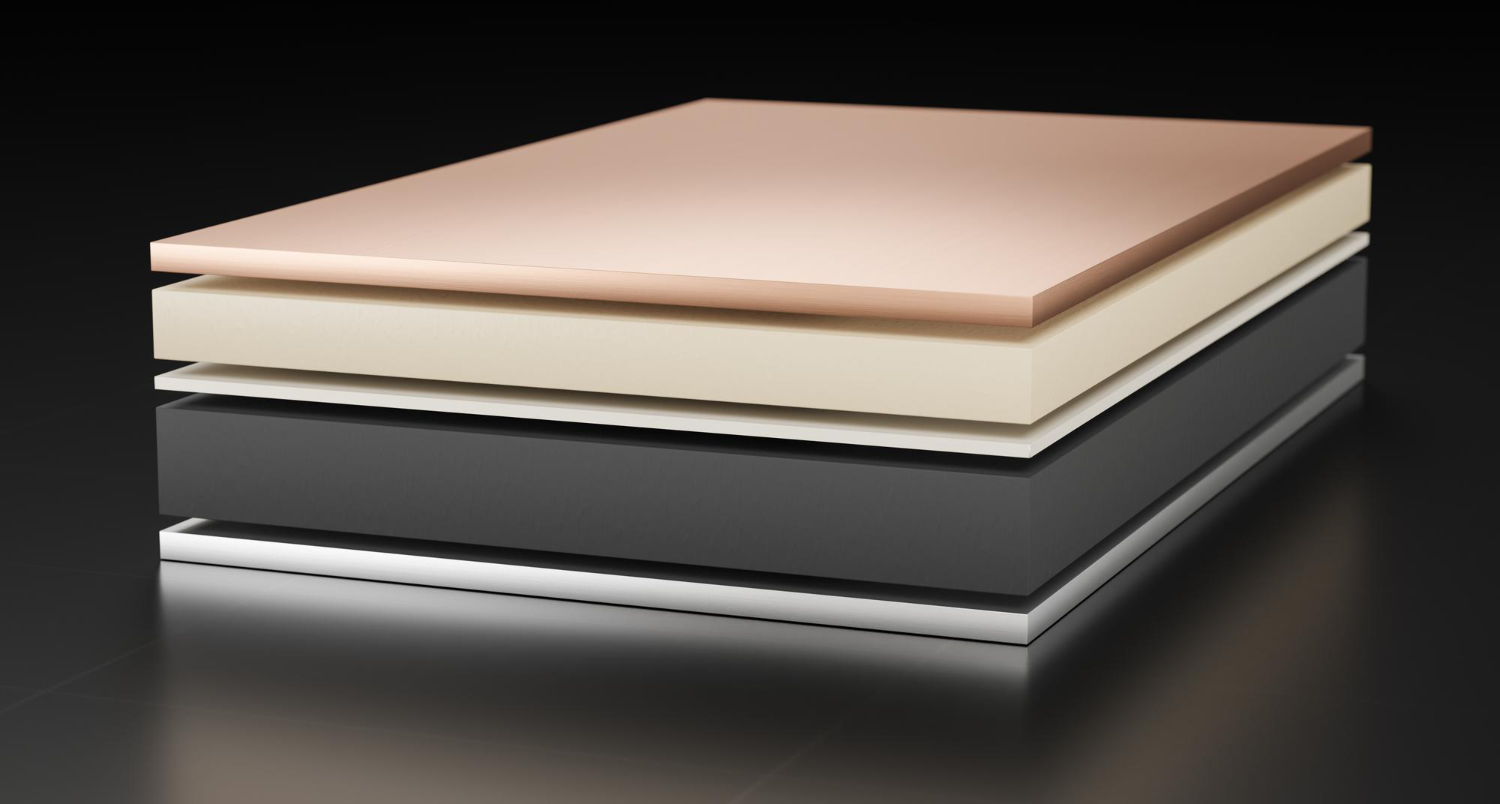

The Industrial Liquid filtration system is configured with horizontally positioned filter plates with holes. These plates are positioned uniformly in a vertical tank. The plates have varying depths depending on the filtration surface and cake volumes. The fluid to be filtered passes over these horizontal filter plates which can be fitted with different kinds of filter media. The solid particles then collect in the form of a filter cake, which then remains on the filter medium and the polished liquid flows through the filter plates to the filtrate outlet.

The industrial liquid filtration system can be used for numerous batch and continuous filtration processes. It is easy to maintain as it contains no moving parts, the filter cartridges can be quickly removed and replaced with a spare cartridge. Its applications include, removal of activated carbon, filtration of varnishes, paints and resins, removal and recovery of catalysts, purification of chemicals, recovery of precious metals, processing of edible oils, juices, glucose and also in the pharmaceutical industry.

Benefits

- Any filter media can be used

- Filter plates are easy to clean

- High flow rates at low pressure drop

- Flexibility in operation

- Permits easy cake washing and drying