Zero effluent discharge system for solvent extraction plants

Eliminate wastewater in your solvent extraction process while reducing energy costs and simplifying permit applications with an innovative zero effluent discharge system.

Eliminates Wastewater and Recycles Steam

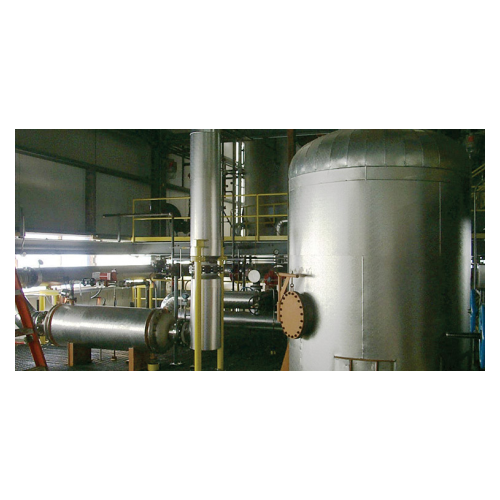

The Zero Effluent Discharge System by Crown Iron Works is engineered for manufacturers dedicated to minimizing environmental impact while maintaining efficient operations. This system efficiently eliminates wastewater by converting it into reusable steam, utilizing specially designed pressure vessels that integrate seamlessly into a solvent extraction plant. Typical applications include biofuel production, hemp CBD oil extraction, and specialty chemical processing, with end products such as biodiesel, plant-based proteins, and omega-3 supplements. Capable of adapting to continuous, automated operations, the system aids in achieving significant energy savings by raising condensate returns from 40% to 80%, reducing both energy consumption and chemical treatment costs. Designed for robust integration, it supports various solvents and processes such as desolventization and steam generation, making it a versatile choice for diverse industries including nutraceuticals and food products. Additionally, the system can incorporate additional wastewater sources, further enhancing its recycling capabilities.

Benefits

- Reduces energy costs by increasing steam condensate return from 40% to 80%.

- Minimizes wastewater disposal fees and environmental impact.

- Streamlines permit processes by eliminating major effluent sources.

- Enhances product quality with improved meal drying and solvent recovery.

- Supports operational efficiency with additional wastewater recycling integration.

- Applications

- Polymers, Specialty chemicals, Fibers, Nutraceuticals, Plant-based proteins, Fats, Oils, Waxes, Food products, Biofuel, Hemp cbd oil extraction, Pharmaceuticals

- End products

- Polyethylene, Canola oil, Specialty solvents, Hemp cbd oil, Sunflower oil, Paraffin wax, Kevlar fibers, Pain relievers, Omega-3 supplements, Plant-based meat, Biodiesel, Soybean oil

- Steps before

- Oilseed Preparation, Solvent Extraction, Blowdown Water Collection, Pressure Vessels Concentration

- Steps after

- Steam Recycling, Meal Drying, Wastewater Recycling, Digestible Protein Enhancement

- Input ingredients

- wastewater, blowdown water, solvent

- Output ingredients

- 40 psig steam, superheated sparge steam, condensate, dried meal

- Market info

- Crown Iron Works is renowned for its expertise in designing and manufacturing engineered-to-order equipment for oilseed processing and edible oil extraction, with a strong reputation for innovation, reliability, and delivering customized solutions worldwide.

- Steam Pressure

- 40 psig

- Condensate Return Rate

- 80% of total steam consumption

- Sparge Steam Supply

- 75-100% for Desolventizer-Toaster operation

- Boiler Efficiency

- Increased by returning up to 80% condensate

- Working mechanism

- Pressure vessels

- Integrated steps

- Concentration and recycle

- Steam generation

- 40 psig steam

- Energy optimization

- Condensate return 40%-80%

- Wastewater integration

- Incorporation of multiple sources

- Operation type

- Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Application

- Solvent Extraction Plant

- Footprint Size

- Compact

- Pressure Vessel Shape

- Cylindrical

- Tank Size

- Customizable

- Feed/Discharge Method

- Integrated Recycling

- Steam Generation Capability

- 40 psig

- Sparge Steam Supply

- 75–100% of Plant Need

- Control panel type

- PLC / HMI

- Integration possibilities

- Plant-wide systems / Existing process integration

- Pressure vessel design

- Customizable to requirements

- Sparge steam supply

- Adjustable range