High performance heat transfer system

Enhance your production efficiency with a system that shortens cycle times by increasing heat transfer area, optimizing thermal management in batch and continuous operations.

Enhances Heat Transfer and Mixes Chemical Reactions

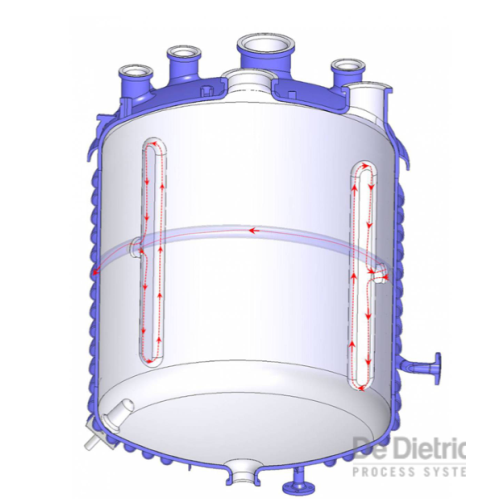

The OptiMix® – HE from De Dietrich Process Systems is a glass-lined heat exchange reactor designed for precision thermal control in demanding industries such as pharmaceuticals and specialty chemicals. It utilizes a unique half-coil system and integral wall-mounted baffles to increase heat transfer rates and reduce processing times. Ideal for producing APIs and specialty polymer additives, it supports both batch and continuous operations across various applications, including biopharmaceuticals and plant-based chemistry.

The OptiMix® – HE offers a versatile capacity range from 100 liters to 20,000 liters, with a temperature tolerance of -25/+200°C and pressure capabilities of -1/+6 bar. The reactor is PLC-controlled for seamless integration into production lines, promoting efficient thermal management and mixing. Its energy-smart design reduces consumption by up to 25% with enhanced heat transfer areas, promoting sustainable operation.

Manufactured in compliance with DIN 28136 standards, the reactor’s glass lining ensures excellent chemical resistance and durability. Additionally, it features DD3009 enamel, providing robust protection against corrosive substances. The equipment is designed for easy cleaning, thanks to its no dead zone and minimized vortex to prevent splashing, making maintenance straightforward and reducing downtime. Customization options are available to meet specific production needs, supported by De Dietrich’s comprehensive engineering and after-sales service.

Benefits

- Accelerates processing time with enhanced heat transfer and efficient mixing.

- Reduces energy consumption by up to 25%, optimizing operational costs.

- Ensures long-term durability with high corrosion resistance in aggressive environments.

- Simplifies maintenance with easy-to-clean design and reduced downtime.

- Integrates seamlessly into production lines, boosting productivity through automated control systems.

- Applications

- Agricultural chemicals, Specialty chemicals, Fine chemicals, Biopharmaceuticals, Essential oils, Precious metals, Plant-based chemistry, Biofuel, Pharmaceuticals

- End products

- Lavender essential oil, Active pharmaceutical ingredients (apis), Monoclonal antibodies, Plant extracts, Catalytic converters, Pesticide formulations, Biodiesel, Specialty polymer additives

- Steps before

- Purification, Grinding, Mixing, Emulsification

- Steps after

- Cooling, Storage, Packing

- Input ingredients

- thermal fluid, reactants for pharmaceutical production, reactants for specialty chemical production

- Output ingredients

- improved heat exchange surface, faster thermal management, processed pharmaceutical APIs, processed specialty chemicals

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Heat transfer area increase

- up to 25%

- Capacity

- 100 l up to 20, 000 l

- Temperature range (inside)

- -25/+200°C

- Temperature range (outside)

- -25/+200°C

- Pressure range

- -1/+6 bar

- Material

- DD3009 Enamel

- Batch vs. continuous operation

- Batch or Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Heat exchange performance

- Increased by up to 25%

- Temperature operating range

- -25/+200°C

- Pressure operating range

- -1/+6 bar

- Material handling

- Glass-lined reactor

- Reaction time reduction

- Reduced due to improved mixing

- Clearance

- No dead zones

- Cleanability

- Improved cleaning facilities, no dead zone

- Corrosive resistance (e.g. acids)

- DD3009 Enamel

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Capacity

- 100 L to 20, 000 L

- Temperature Range

- -25°C to +200°C

- Pressure Range

- -1 to +6 bar

- Jacket Type

- Half-coil

- Baffle Design

- Three integral wall mounted baffles

- Lining Material

- DD3009 Enamel

- Heat Exchange Area Increase

- Up to 25%

- Size Range

- 100 l to 20, 000 l

- Temperature Range

- -25 to +200°C

- Pressure Range

- -1 to +6 bar

- Material Type

- Glass-lined

- Baffle Design

- Three integral wall mounted baffles

- Geometry Standard

- DIN 28136

- Enamel Type

- DD3009