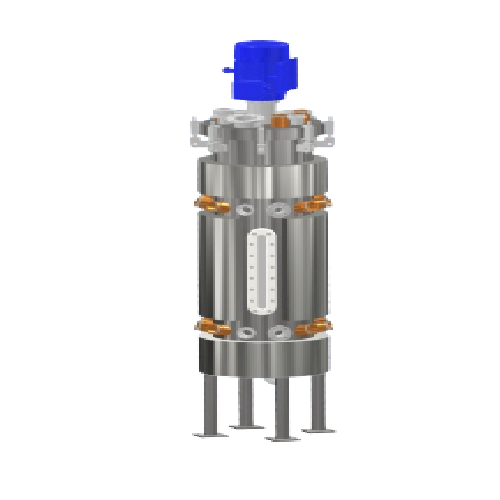

Pilot-scale bioreactors for bioprocess scale-up

Bridge the gap between experimentation and large-scale production with pilot-scale bioreactors, mastering precise environmental control and adaptable configurations for seamless and reliable bioprocess scale-up.

Facilitates Fermentation and Customizes Bioprocesses

The pilot-scale bioreactors from n!Biomachines are an indispensable tool for biopharmaceutical companies, biotechnology firms, and nutraceutical manufacturers seeking precision in scale-up processes. These bioreactors provide a critical bridge from lab-scale experimentation to commercial production, ensuring consistency in products such as monoclonal antibodies, vaccines, and probiotic supplements. With volumes ranging from 200 to 5000 liters, they accommodate a wide range of applications, including cultivated meat and alternative protein sources. Equipped with advanced control systems, including the AUXO V® technology, they allow for meticulous environmental parameter manipulation to optimize growth conditions. The modular design supports extensive integration into existing workflows and allows for tailored configurations to meet specific production needs. Constructed from long-lasting materials, these units offer robust performance in demanding bioprocesses and include advanced sensor technology for real-time monitoring. Cleaning and maintenance are streamlined with options for CIP/SIP systems, ensuring operational efficiency while minimizing downtime. Each unit can be customized with software and hardware options to fit exact processing requirements, while ensuring compliance with industry standards for safety and quality.

Benefits

- Ensures seamless scale-up with precise control systems, maintaining product consistency.

- Adapts to specific process needs with customizable configurations, enhancing production flexibility.

- Minimizes downtime with easy-clean systems, reducing labor and maintenance costs.

- Improves efficiency with real-time monitoring, optimizing growth conditions and preventing failures.

- Facilitates integration into existing operations, streamlining workflow and enhancing productivity.

- Applications

- Alternative protein sources, Fermented products, Nutraceuticals, Biopharmaceuticals, Enzymes, Cultivated meat

- End products

- Lab-grown beef, Quorn, Vaccines, Plant-based chicken, Vegan cheese, Amylase, Monoclonal antibodies, Probiotic supplements, Vitamin-enhanced supplements, Proteases, Lactase, Soy-based yogurt, Tofu, Tempeh

- Steps before

- Laboratory-scale experimentation, Small-scale experiments, Process development

- Steps after

- Scale-up to commercial production, Bioprocessing scale-up, Nutritional and health product formulation

- Input ingredients

- cell culture media, microorganisms, nutrients, bioprocess fluids

- Output ingredients

- bioproducts, cultivated meat, proteins, biomaterials

- Market info

- Capacity

- 200–5000 liters

- Control System

- Advanced control systems

- Customization

- Highly customizable design

- AUXO V® Technology

- Precision environmental control

- Integration Capabilities

- Extensive integration

- Sensor Technology

- Advanced sensor technology

- Impellers

- Shear stress optimization for cell types

- CIP/SIP System

- Available upon request

- Monitoring System

- Automated monitoring and alert

- Component Design

- Component-based design

- Scale-up capability

- 200 to 5000 liters

- Advanced control systems

- Precise manipulation of environmental parameters

- Customization

- Modular components and flexible configurations

- Integration capabilities

- Designed to fit into existing workflows

- Automation level

- AUXO V® control systems

- CIP/SIP

- Available upon request

- Sensor technology

- High-quality sensors for accurate, real-time monitoring

- Cleaning method

- Easy-clean and self-cleaning mechanisms

- Changeover time

- Component-based design for simplified upgrades

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank capacity

- 200–5000 liters

- Control panel type

- Intuitive interfaces

- Modularity

- Modular components

- Discharge method

- Customizable input/output options

- Material usage

- Long-lasting materials

- Easy-clean systems

- Self-cleaning mechanisms or easy disassembly

- Control panel type

- Intuitive interface

- Integration capabilities

- Customizable input/output options

- Software

- Customizable interfaces

- Modular design

- Flexible configurations

- Impellers

- Optimized for different organisms