Dispensing isolator for hazardous substance handling

Ensure maximum operator safety and contamination control when handling hazardous substances with this advanced glove box system, maintaining a strict separation between the internal environment and external workspace.

Ensures Safe Dispensing and Isolation

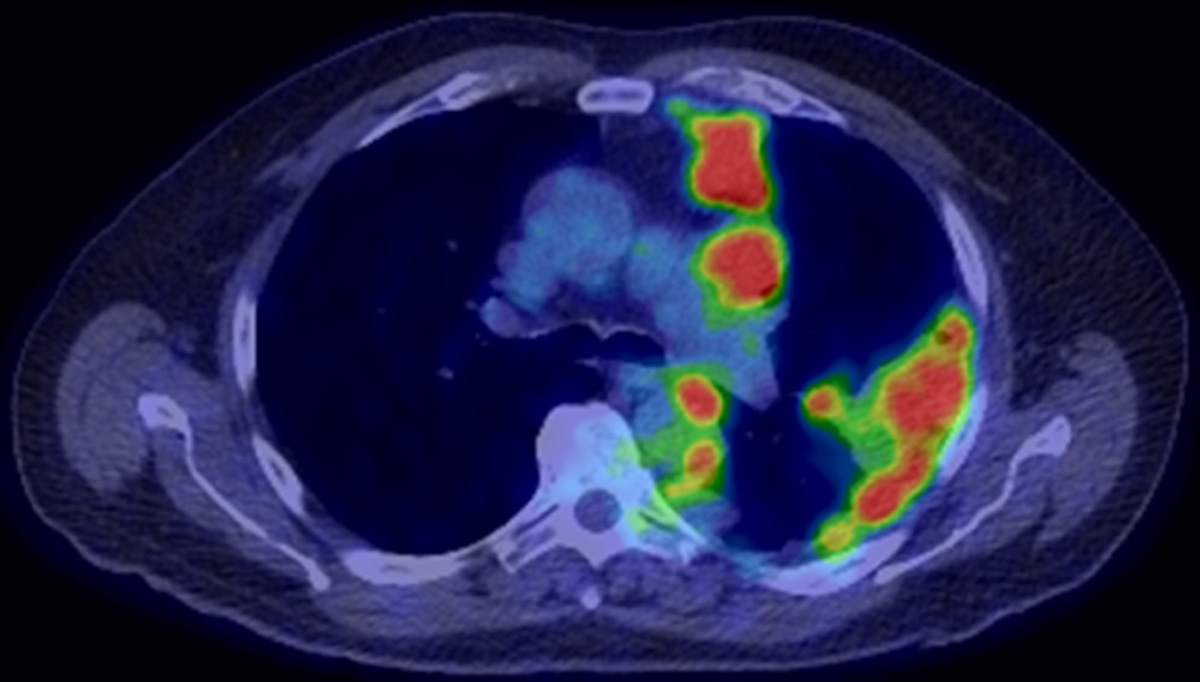

The Dispensing Isolator Glove Box from Comecer is expertly designed for environments demanding precision and safety in material handling, particularly within the pharmaceutical, radiopharmaceutical, and cell & gene therapy sectors. Specially engineered to maintain separation between operators and hazardous materials, this system utilizes negative pressure and turbulent air flow to ensure containment. Ideal for applications in dispensing, containment, and isolation, it’s widely employed in the production of radiopharmaceuticals like Fluorodeoxyglucose (FDG), Iodine-131, and Technetium-99m, as well as chemotherapy drugs and monoclonal antibodies.

This glove box system boasts a fully PLC-controlled operation, which allows for both automated and manual processes, offering flexibility in various pharmaceutical settings. It features a bag-in/bag-out filter replacement method, ensuring minimal exposure during maintenance. Compliant with GMP standards, it supports stringent contamination control required in laboratory departments focusing on safety and environmental conditions.

Notably, the system accommodates a wide range of materials—solid, liquid, and powder—making it versatile for various production requirements. Comecer provides engineering support to customize configurations to meet specific operational needs, thereby integrating seamlessly into existing production lines.

Benefits

- Ensures operator safety by maintaining a controlled, isolated environment.

- Increases operational efficiency with fully PLC-controlled processes.

- Minimizes contamination risk with ergonomic negative pressure and turbulent air flow systems.

- Streamlines maintenance and minimizes exposure with bag-in/bag-out filter replacement.

- Complies with GMP standards to meet stringent pharmaceutical industry requirements.

- Applications

- Aseptic pharmaceuticals, Gene therapy products, Cell, Radiopharmaceuticals, Nuclear medicine products, Pharmaceutical compounds

- End products

- Radiolabeled antibodies, Gene therapy vectors, Monoclonal antibodies, Car-t cell products, Chemotherapy drugs, Sterile intravenous solutions, Lutetium-177, Iodine-131, Technetium-99m, Fluorodeoxyglucose (fdg)

- Steps before

- Substance Preparation, Transfer to Isolator, Initial Setup

- Steps after

- Decontamination, Filter Replacement, Quality Control

- Input ingredients

- manual handling substances, materials for dispensing

- Output ingredients

- safely dispensed materials, isolated products

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Glove box chambers

- Two

- Pressure Control

- Negative pressure

- Airflow

- Turbulent air flow

- Filter Replacement Method

- Bag-in/Bag-out

- Automation

- Fully PLC controlled

- Cleanability

- Fully washable

- Working Mechanism

- Glove Box System

- Isolation Level

- Negative Pressure

- Airflow Type

- Turbulent Air Flow

- Filter Replacement Method

- Bag-in/Bag-out

- Automation Level

- Fully PLC Controlled

- Cleanability

- Fully Washable

- Chamber Configuration

- Two Glove Box Chambers

- Number of Chambers

- Two glove box chambers

- Glove Box Type

- Dispensing isolator

- Pressure Type

- Negative pressure

- Airflow Type

- Turbulent air flow

- Control panel type

- Fully PLC controlled

- Integration possibilities

- Glove Box System

- Number of chambers

- Two glove box chambers

- Filter replacement method

- Bag-in/Bag-out